Vertical substrate grown cyclodextrin intercalation hydrotalcite film and preparation thereof

A technology of cyclodextrin and hydrotalcite, which is applied in the direction of hydrotalcite, chemical instruments and methods, coatings, etc., to achieve the effect of strong action and not easy to fall off

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0024] Step A: Cut the aluminum sheet into 10cm×10cm pieces, ultrasonically clean them in absolute ethanol and deionized water for 3 minutes, then put them in 0.1M NaOH solution for 2 minutes, and rinse them with deionized water. The cleaned aluminum sheet was used as the anode, the lead sheet was used as the cathode, and 1M H 2 SO 4 The solution is used as electrolyte, and it is oxidized at constant pressure. The working voltage is 20V, and the oxidation area of the aluminum sheet is about 100cm 2 , the oxidation current is 2A, the electrolysis time is 1h, and the electrolysis temperature is room temperature, so that an anodized aluminum oxide layer is formed on the surface of metal aluminum. During the oxidation process, small bubbles (H 2 ) produced, the surface of the anodized aluminum sheet after drying is white (for Al 2 o 3 film color). The samples were washed with a large amount of deionized water and dried at 70°C for later use.

[0025] Step B: take by weigh...

Embodiment 2

[0028] Step A: Obtain an AAO / Al substrate according to the method of Step A in Example 1.

[0029] Step B: take by weighing 2.974g Zn (NO 3 ) 2 ·6H 2O (0.1mol), 0.5g carboxymethylcyclodextrin (degree of substitution 4.1) and 4.8g NH 4 NO 3 (0.6mol) was dissolved in deionized water to make 100ml reaction synthesis solution, and then 1% NH 3 ·H 2 O adjusts the pH of the reaction synthesis liquid to 6.5. An anodized aluminum oxide / aluminum (AAO / Al) substrate with a size of 1 cm×2 cm was vertically suspended in the above reaction synthesis liquid, and reacted at 75° C. for 48 h. After the reaction, the sample is taken out, rinsed with deionized water, and dried at room temperature to obtain a cyclodextrin-intercalated hydrotalcite film.

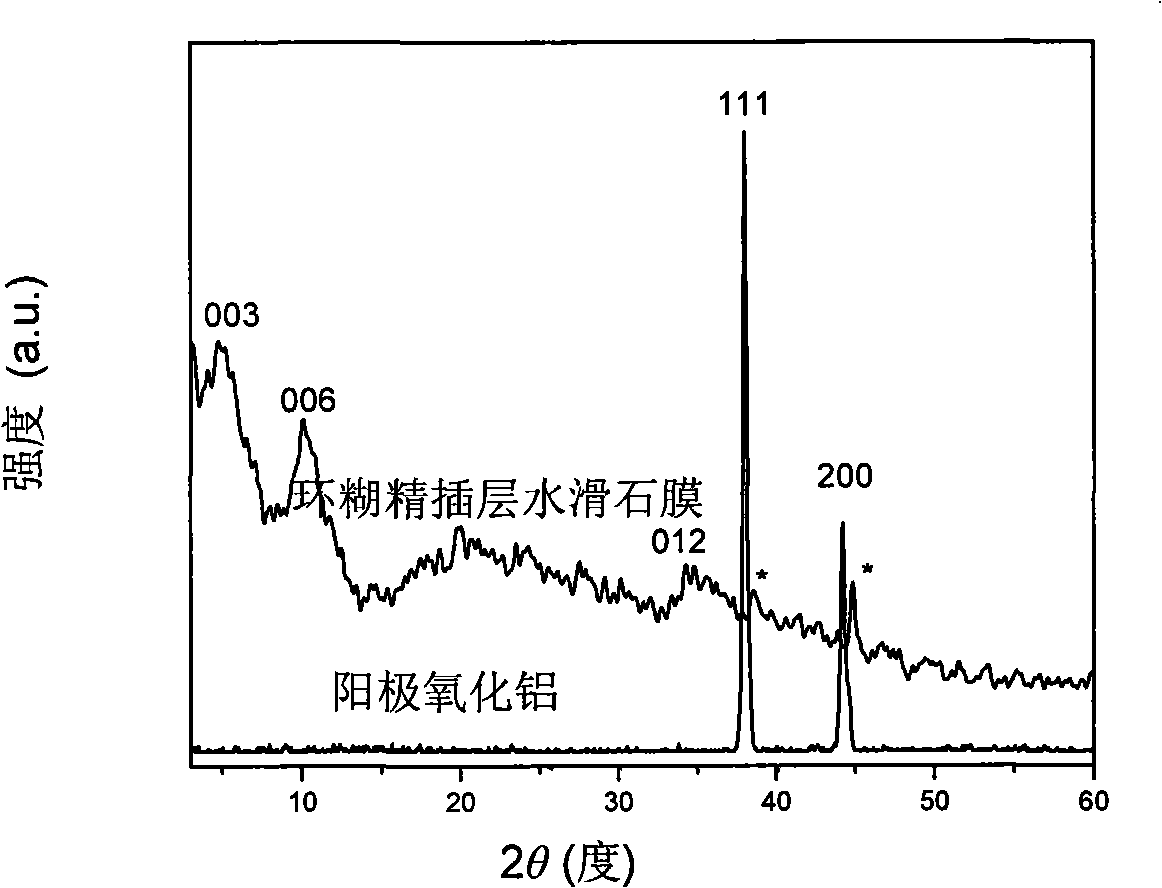

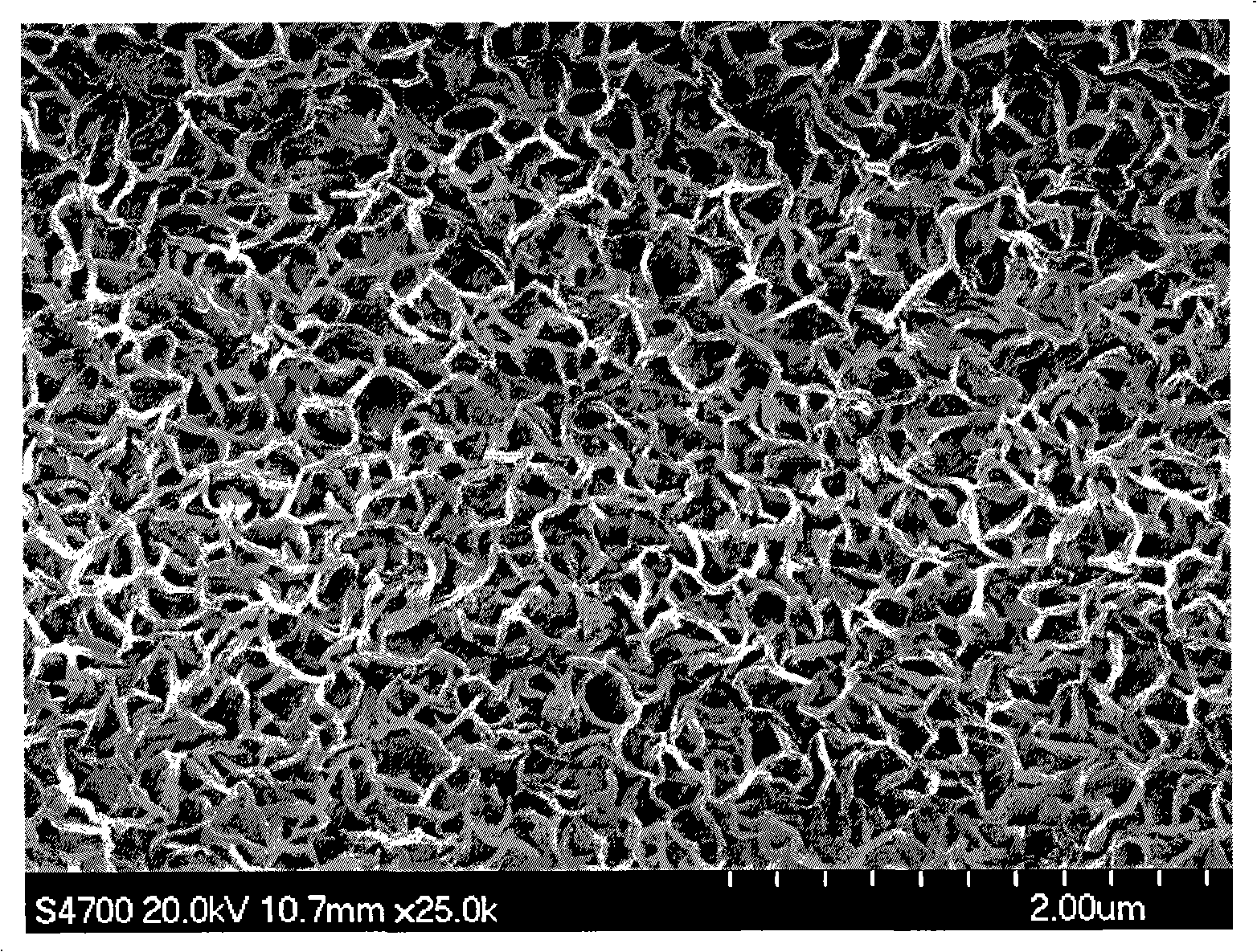

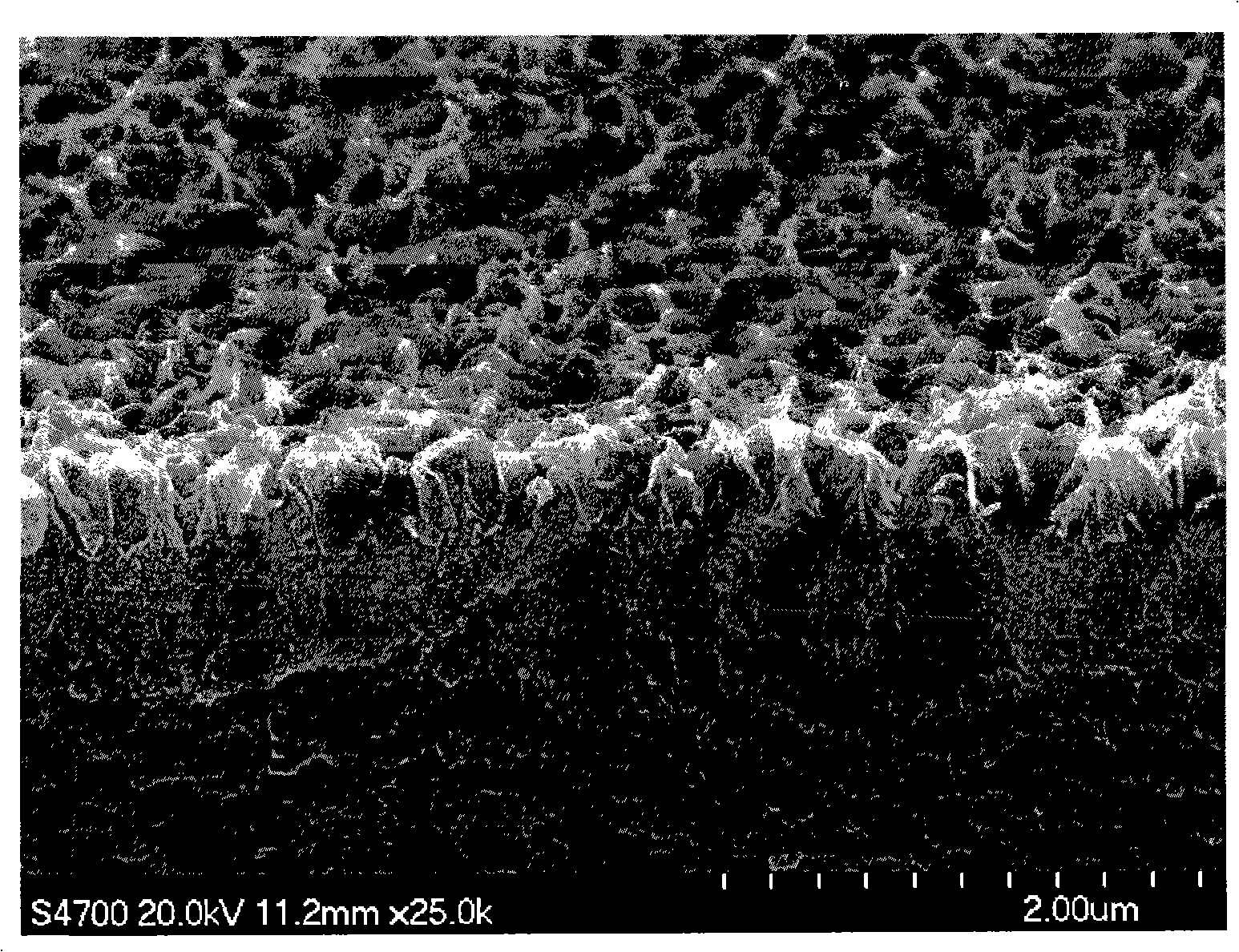

[0030] It can be seen from the X-ray diffraction pattern that the cyclodextrin-intercalated hydrotalcite prepared by the in-situ growth method, carboxymethyl-β-cyclodextrin can enter the interlayer of the hydrotalcite film, and the interla...

Embodiment 3

[0032] Step A: Obtain an AAO / Al substrate according to the method of Step A in Example 1.

[0033] Step B: Weigh 2.932g Co(NO 3 ) 2 ·6H 2 O (0.1mol), 0.5g carboxymethylcyclodextrin (degree of substitution 4.1) and 4.8g NH 4 NO 3 (0.6mol) was dissolved in deionized water to make 100ml reaction synthesis solution, and then 1% NH 3 ·H 2 O adjusts the pH of the reaction synthesis liquid to 6.5. An anodized aluminum oxide / aluminum (AAO / Al) substrate with a size of 1 cm×2 cm was vertically suspended in the above reaction synthesis liquid, and reacted at 75° C. for 48 h. After the reaction, the sample is taken out, rinsed with deionized water, and dried at room temperature to obtain a cyclodextrin-intercalated hydrotalcite film.

[0034] It can be seen from the X-ray diffraction pattern that the cyclodextrin-intercalated hydrotalcite prepared by the in-situ growth method, carboxymethyl-β-cyclodextrin enters the interlayer of the hydrotalcite film through ion exchange, and the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com