Nano magnesium-aluminum hydrotalcite and preparation method thereof

A technology of nano-magnesium and aluminum water, which is applied in the field of materials, can solve problems such as easy agglomeration and uneven mixing of precursor powders, and achieve the effects of good repeatability, good dispersion, and cost-saving production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

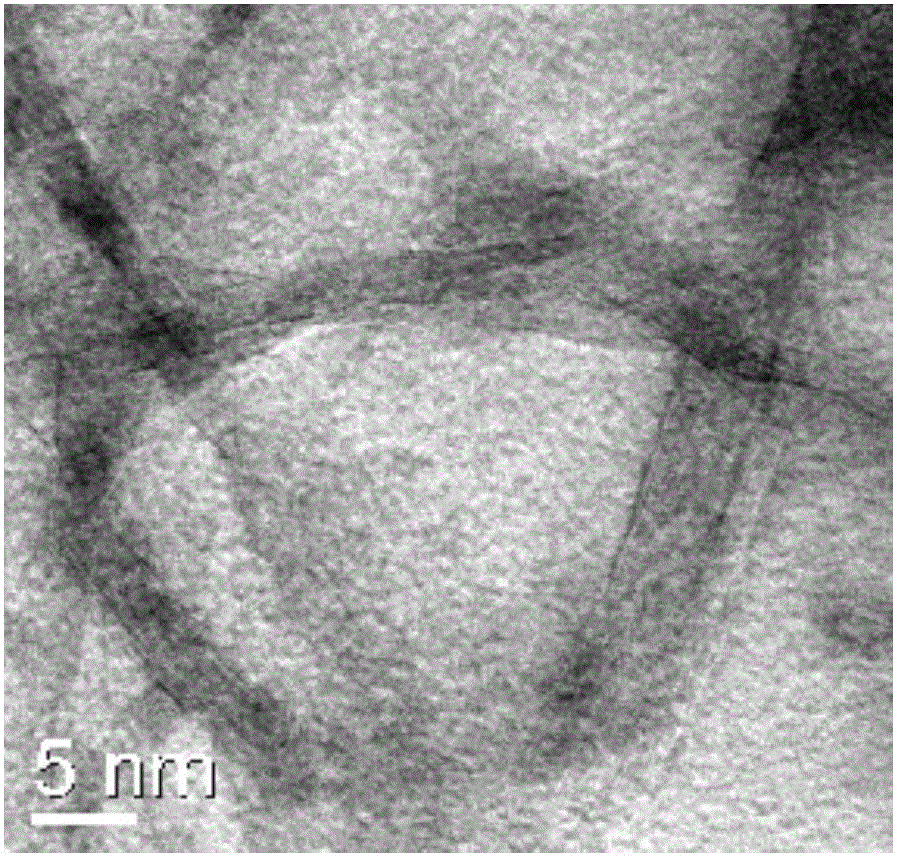

Image

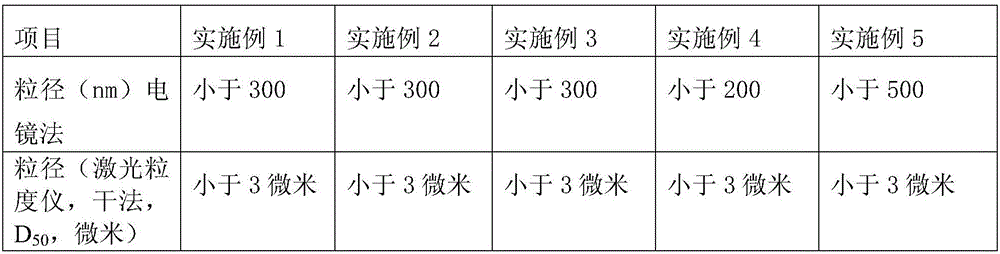

Examples

Embodiment 1

[0037] A nano-magnesium-aluminum hydrotalcite, with magnesium chloride, aluminum chloride, sodium carbonate and sodium hydroxide as the main raw materials, adding foaming agent sodium oleate, first preparing the precursor filter cake through bubble liquid film reaction, and then hydrothermally Made by reaction, filtration, washing and drying.

[0038] The method for preparing nano magnesium aluminum hydrotalcite comprises the following steps:

[0039] 1) Add magnesium chloride and aluminum chloride to a certain amount of water to form Mg 2+ The concentration is 2mol / l, Al 3+ A mixed salt solution with a concentration of 0.8mol / l;

[0040] 2) Add sodium carbonate and sodium hydroxide to a certain amount of water to configure CO 3 2- The concentration is 1mol / l, OH - A mixed alkali solution with a concentration of 6.8mol / l;

[0041] 3) adding the foaming aid sodium oleate into a certain amount of water to form a sodium oleate solution with a concentration of 3g / l;

[0042...

Embodiment 2

[0048] A kind of nano-magnesium aluminum hydrotalcite, with magnesium chloride, aluminum chloride, sodium carbonate and sodium hydroxide as main raw materials, adding foaming aid sodium stearate, first preparing precursor filter cake through bubble liquid film reaction, and then passing water Made by heat reaction, filtration, washing and drying.

[0049] The method for preparing nano magnesium aluminum hydrotalcite comprises the following steps:

[0050] 1) Add magnesium chloride and aluminum chloride to a certain amount of water to form Mg 2+ The concentration is 2mol / l, Al 3+ A mixed salt solution with a concentration of 1mol / l;

[0051] 2) Add sodium carbonate and sodium hydroxide to a certain amount of water to configure CO 3 2- The concentration is 1.5mol / l, OH - A mixed alkali solution with a concentration of 5.6mol / l;

[0052] 3) adding the foaming aid sodium stearate into a certain amount of water to form a sodium stearate solution with a concentration of 3 g / l;...

Embodiment 3

[0059] A nano-magnesium-aluminum hydrotalcite, with magnesium chloride, aluminum chloride, sodium carbonate and sodium hydroxide as the main raw materials, adding foaming agent sodium laurate, first preparing the precursor filter cake through bubble liquid film reaction, and then hydrothermally Made by reaction, filtration, washing and drying.

[0060] The method for preparing nano magnesium aluminum hydrotalcite comprises the following steps:

[0061] 1) Add magnesium chloride and aluminum chloride to a certain amount of water to form Mg 2+ The concentration is 2.25mol / l, Al 3+ A mixed salt solution with a concentration of 1mol / l;

[0062] 2) Add sodium carbonate and sodium hydroxide to a certain amount of water to configure CO 3 2- The concentration is 0.6mol / l, OH - A mixed alkali solution with a concentration of 4.8mol / l;

[0063] 3) adding the foaming aid sodium laurate into a certain amount of water to form a sodium laurate solution with a concentration of 3g / l;

...

PUM

| Property | Measurement | Unit |

|---|---|---|

| concentration | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com