Intercalated hydrotalcite containing double bond organic anion and its uses as heat stabilizer

An organic anion and hydrotalcite technology, which is applied in the treatment of hydrotalcite and dyed low-molecular organic compounds, can solve the problems of not giving full play to the chemical composition of hydrotalcite laminates and the controllability of anion species between layers.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

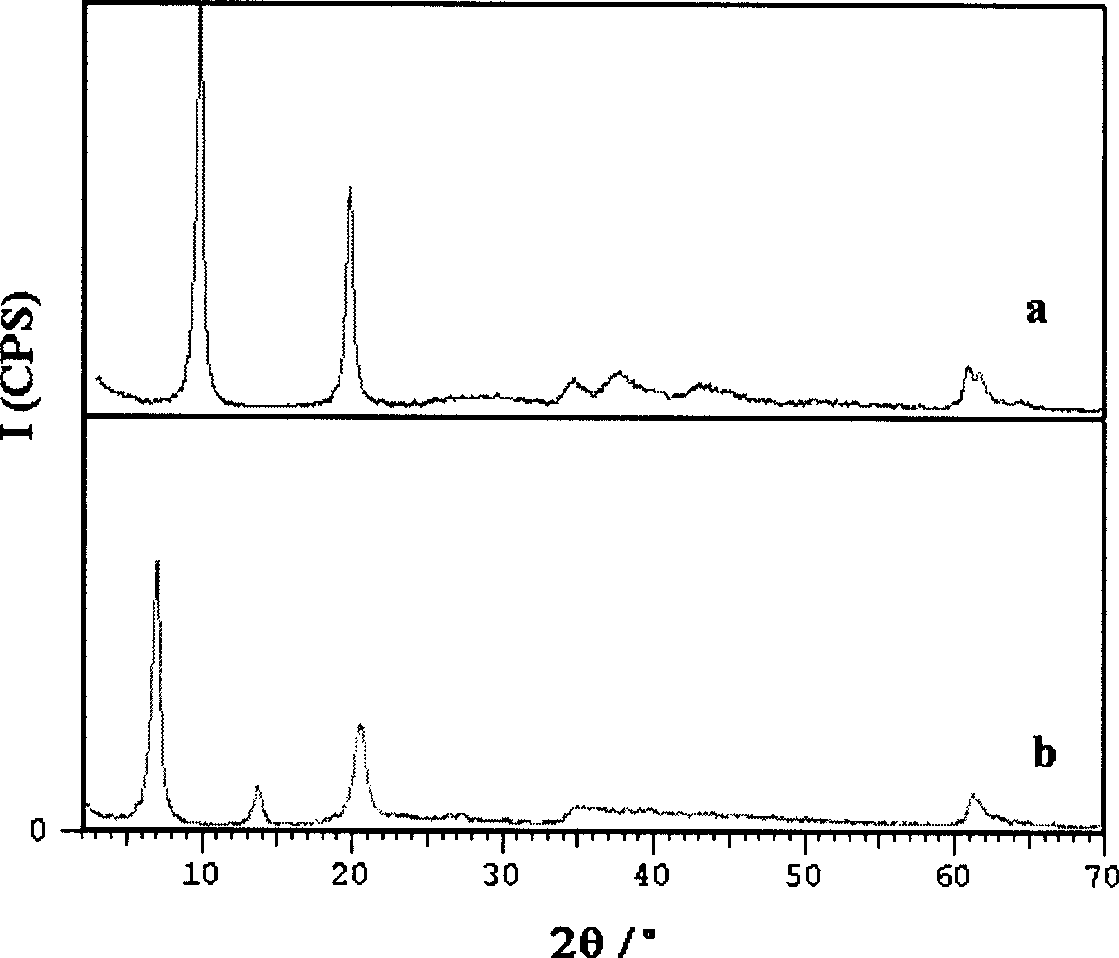

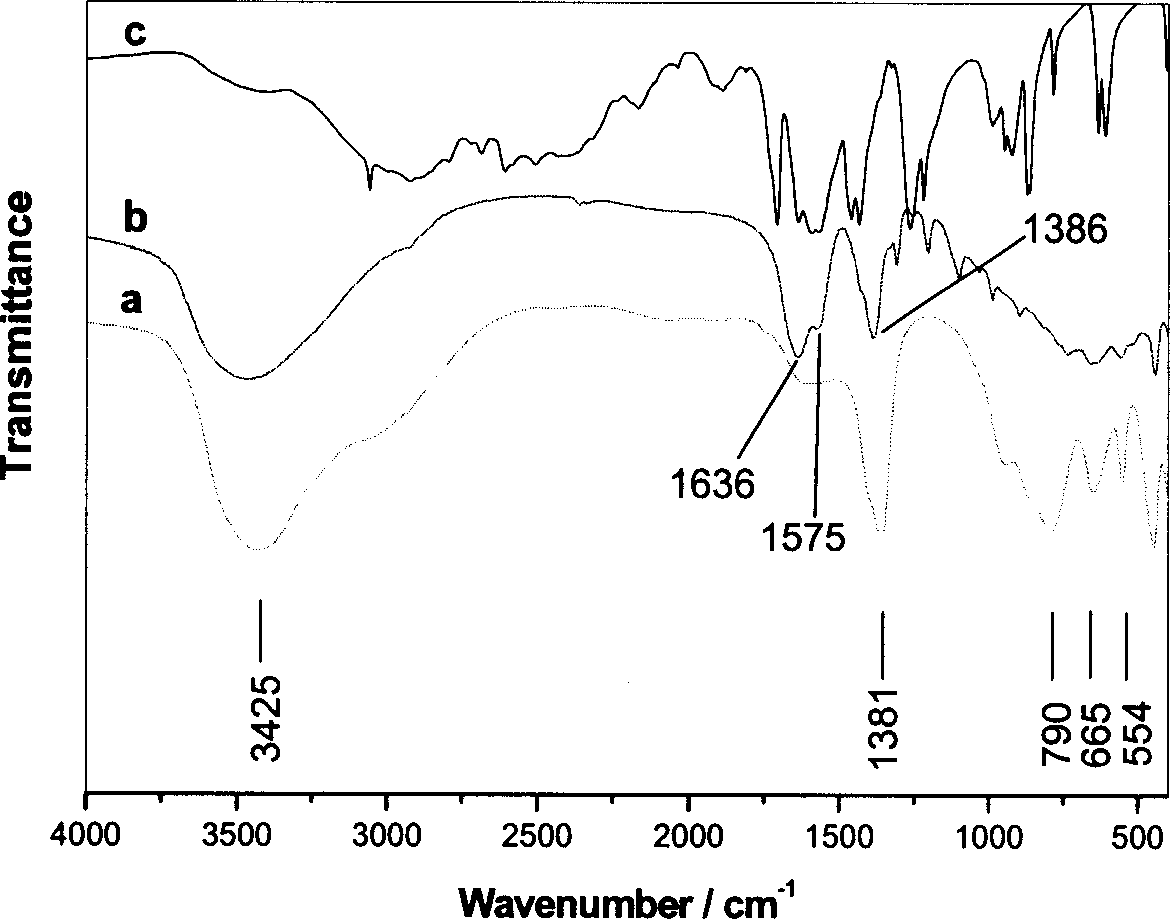

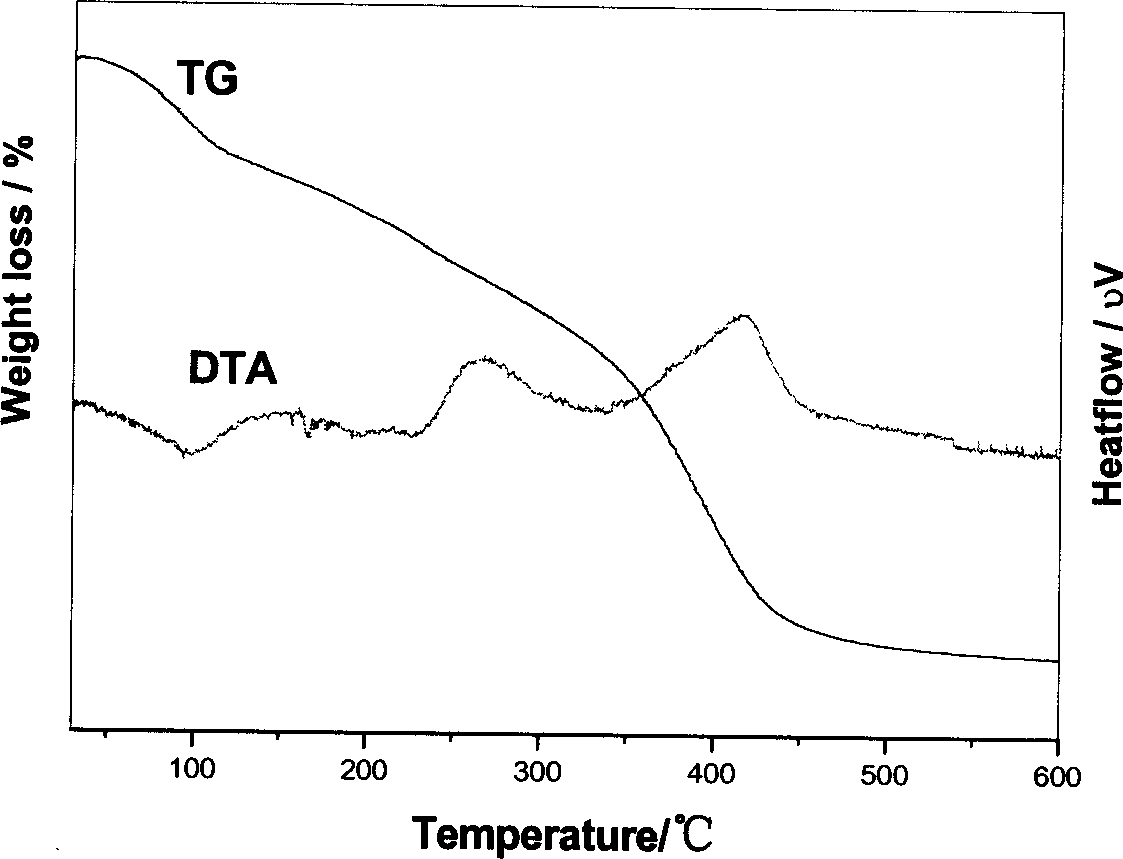

Embodiment 1

[0029] Step A. 10.26g Mg(NO 3 ) 2 ·6H 2 O and 7.50g Al(NO 3 ) 3 9H 2 O dissolves in deCO 2 50ml of mixed salt solution was prepared in deionized water, and 4.8g of NaOH was dissolved in deCO 2 50ml of alkaline solution was prepared in deionized water. Add the two solutions into the reactor simultaneously and react for 3min. 2 Reflux and crystallize at 100°C for 6 hours under protection, filter, and deCO 2 Washed with deionized water to obtain 4.87g Mg:Al=2:1 hydrotalcite precursor filter cake MgAl-NO 3 -LDHs.

[0030] Step B. Disperse the above-mentioned hydrotalcite precursor filter cake in 20ml ethylene glycol, dissolve 2.32g maleic acid in 2.0ml ethylene glycol, control the pH>4.0, add the ethylene glycol solution of maleic acid dropwise The hydrotalcite precursor is heated to the reflux temperature in the ethylene glycol dispersion liquid, reacted for 6 hours, washed and dried to obtain the maleic acid intercalated hydrotalcite. Determined by elemental analysis,...

Embodiment 2

[0033] Step A. 8.20g Mg(NO 3 ) 2 ·6H 2 O, 3.17g Zn(NO 3 ) 2 ·6H 2 O and 8.00gAl(NO 3 ) 3 9H 2 O dissolves in deCO 2 80ml of mixed salt solution was prepared in deionized water, and 1.60g of NaOH was dissolved in deCO 2 80ml of alkaline solution was prepared in deionized water. Add the two solutions into the reactor simultaneously and react for 3min. 2 Crystallized at 80°C for 6 hours under protection, filtered, and deCO 2 Washed with deionized water to obtain 5.63g Mg:Zn:Al=3:2:1 precursor filter cake MgZnAl-NO 3 -LDHs.

[0034] Step B. Combine the above MgZnAl-NO 3 -The LDHs precursor filter cake is dispersed in 10ml of ethylene glycol, 4.96g of maleic acid is dissolved in 10ml of ethylene glycol to control the pH>4.0, and the ethylene glycol solution of maleic acid is added dropwise to the hydrotalcite precursor In the ethylene glycol dispersion, heated to reflux, reacted for 1 hour, washed and dried to obtain maleic acid intercalated hydrotalcite, determined b...

Embodiment 3

[0038] Step A. 7.68g Mg(NO 3 ) 2 ·6H 2 O, 8.92g Zn(NO 3 ) 2 ·6H 2 O and 11.25gAl(NO 3 ) 3 9H 2 O dissolves in deCO 2 40ml of mixed salt solution was prepared in deionized water, and 5.28g of NaOH was dissolved in deCO2 2 40ml of alkaline solution was prepared in deionized water. Add the two solutions into the reactor simultaneously and react for 3min. 2 Reflux crystallization at 100°C for 6 hours under protection. The obtained product was deCO 2 Washed with deionized water and filtered to obtain 8.54g MgZnAl-NO of Mg: Zn: Al=1:1:1 3 - LDHs precursor filter cake.

[0039] Step B. Combine the above MgZnAl-NO 3 - The LDHs precursor filter cake is dispersed in 13ml of ethylene glycol, 5.22g of maleic acid is dissolved in 9ml of ethylene glycol, and the pH is controlled to be > 4.0, and the ethylene glycol solution of maleic acid is added dropwise to the ethylene glycol of the hydrotalcite precursor In the diol dispersion liquid, heated to reflux, reacted for 4 hours...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Decomposition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com