Magnesium aluminum hydrotalcite and method for preparing magnesium aluminum hydrotalcite

A magnesium-aluminum hydrotalcite and magnesium-aluminum technology, which is applied in the field of hydrotalcite, can solve the problems of poor crystallinity, complicated methods, and high cost of magnesium-aluminum hydrotalcite, and achieve the effects of low price, wide sources, and high crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

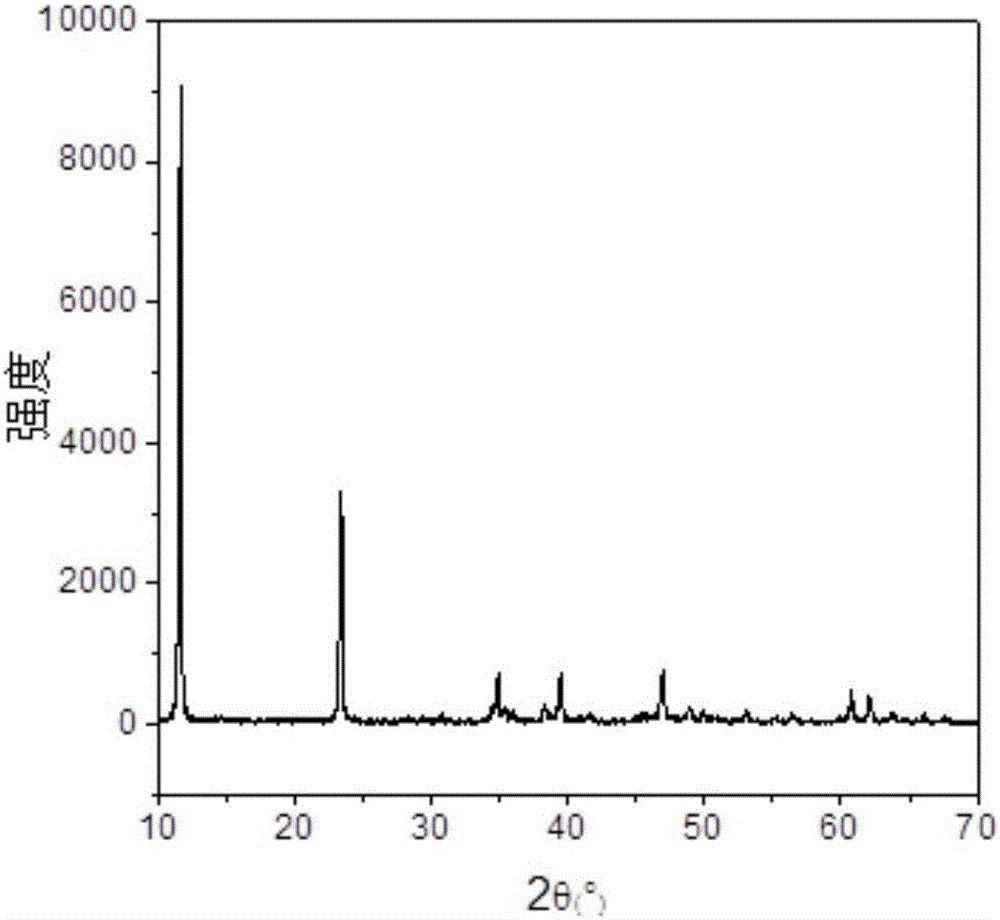

Embodiment 1

[0066] (1) Preparation of sol precursor

[0067] Add 50g of activated magnesium oxide (purchased from Haicheng Huasheng Refractory Co., Ltd., the brand is 90, the same below) into the ball mill tank, add 500ml of water, and pass through the ball mill at a speed of 800r / min for 2 hours to obtain the sol precursor;

[0068] (2) Preparation of magnesium-aluminum composite sol

[0069] Take 100ml of sol precursor, add water to dilute to 2L, add 150g magnesite (purchased from Haicheng Huasheng Refractory Co., Ltd., the brand is 40-70, the same below) and 60g aluminum hydroxide (purchased from Luoyang Zhongchao New Material Co., Ltd. The brand name of the joint stock company is AH-01DG, the same below); after stirring evenly, 5g of acetic acid + 3g of oxalic acid were added to it, and kept at 80°C for 30min to obtain a magnesium-aluminum composite sol. The pH value of the magnesium-aluminum composite sol is 4.3;

[0070] (3) Preparation of magnesium aluminum hydrotalcite slurry by...

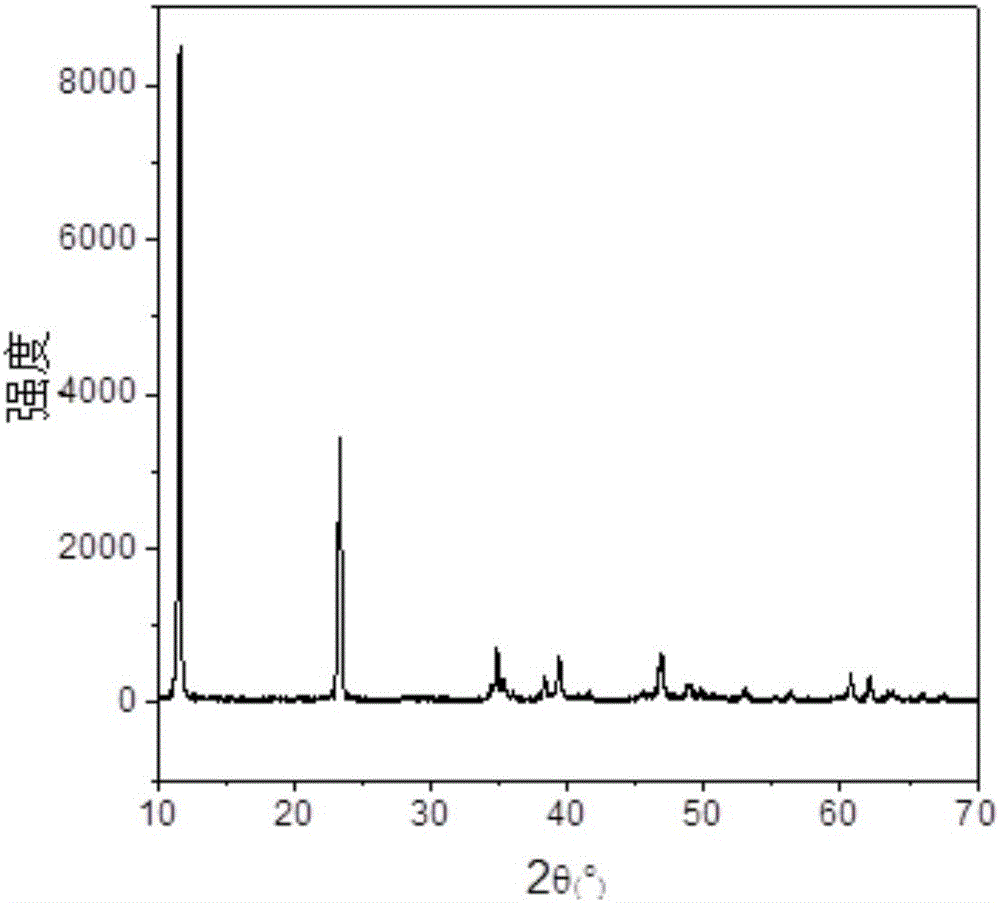

Embodiment 2

[0075] (1) Preparation of sol precursor

[0076] Add 50 g of active magnesium oxide into a ball mill jar, add 150 ml of water, and mill for 2 hours at a speed of 800 r / min in a ball mill to obtain a sol precursor.

[0077] (2) Preparation of magnesium-aluminum composite sol

[0078] Take 100ml of sol precursor and add water to dilute to 2L, add 100g of magnesite, 30g of active magnesium oxide and 60g of aluminum hydroxide to it; stir evenly, add 5g of oxalic acid and 2ml of nitric acid with a concentration of 3mol / L to it, at 30°C Insulated for 300 minutes to obtain magnesium-aluminum composite sol. The pH value of the magnesium-aluminum composite sol is 3.8;

[0079] (3) Preparation of magnesium aluminum hydrotalcite slurry by hydrothermal method

[0080] The magnesium-aluminum composite sol that step (2) obtains is joined in the autoclave (pressure is 2MPa), and adds 54g Na wherein 2 CO 3 and 30g of sodium acetate, hydrothermally reacting at 220°C for 2h, after filterin...

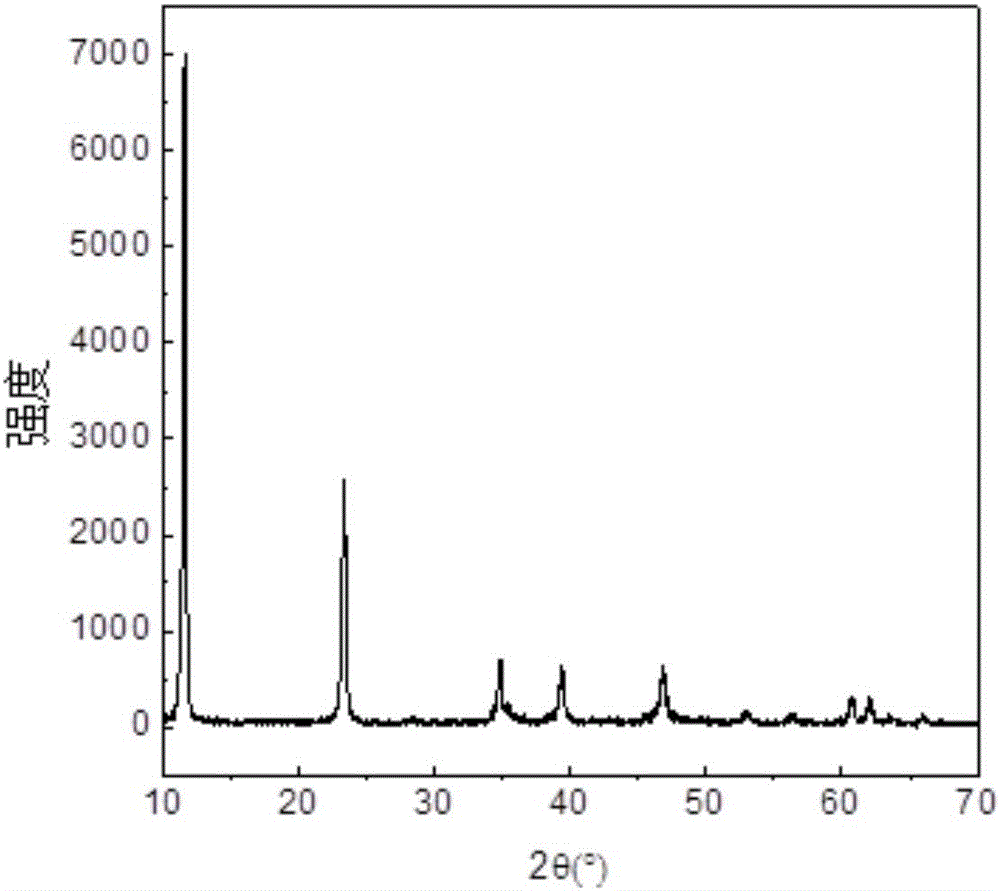

Embodiment 3

[0084] (1) Preparation of sol precursor

[0085] Add 30g of activated magnesium oxide and 20g of aluminum hydroxide into a ball mill jar, add 250ml of water, and mill for 2 hours at a speed of 800r / min in a ball mill to obtain a sol precursor.

[0086] (2) Preparation of magnesium-aluminum composite sol

[0087] Take 100ml of the sol precursor and dilute it to 2L with water, add 150g of magnesite and 60g of aluminum hydroxide to it; stir well, add 2ml of hydrochloric acid with a concentration of 3mol / L and 3g of oxalic acid into it, and keep it at 50°C for 60min to obtain magnesium aluminum Composite sol. The pH value of the magnesium-aluminum composite sol is 4.3.

[0088] (3) Preparation of magnesium aluminum hydrotalcite slurry by hydrothermal method

[0089] Add the magnesium-aluminum composite sol obtained in step (2) into a high-pressure reactor (pressure of 0.5MPa), and add 65g of oxalic acid and 20g of citric acid to it, and conduct a hydrothermal reaction at 150°C ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com