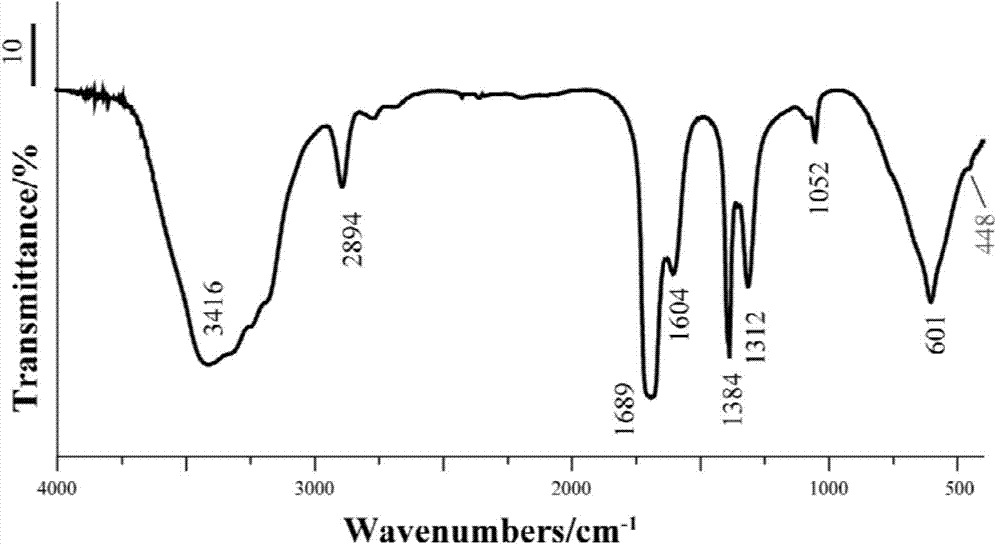

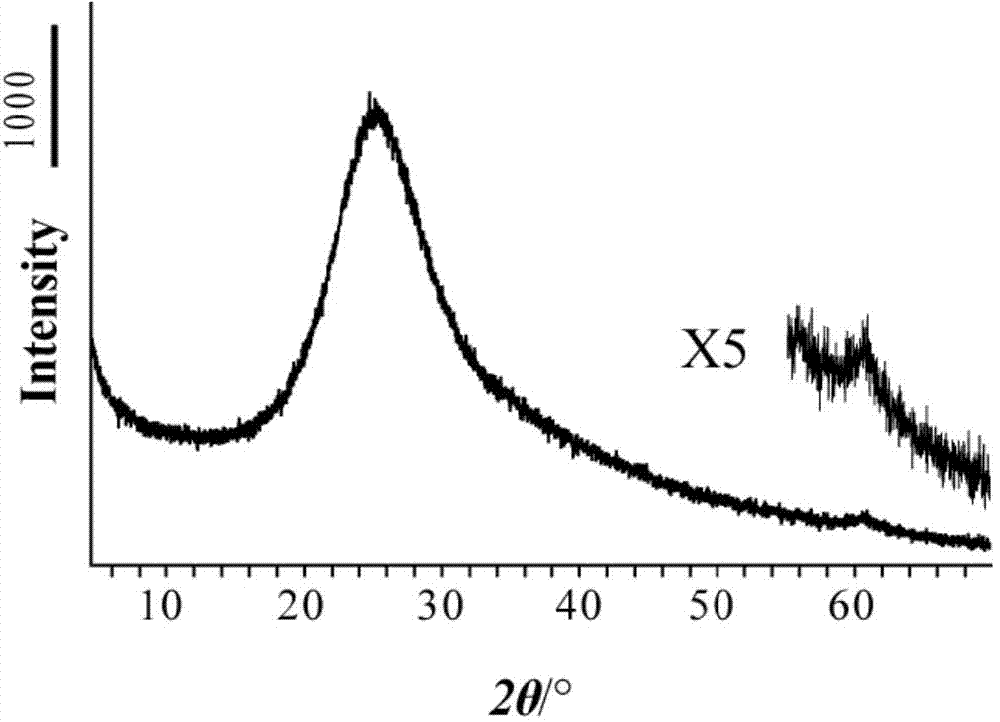

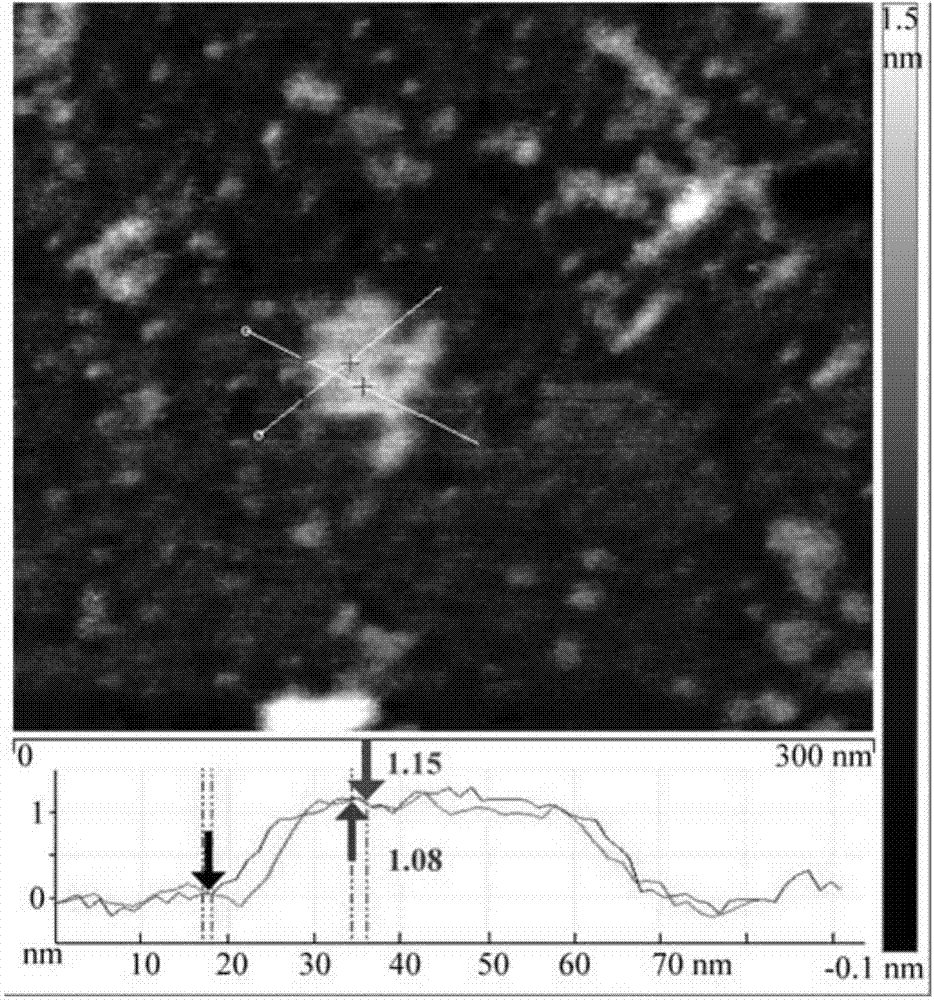

Method for preparing two-dimensional single-layer magnesium-aluminum layered double-metal hydroxide nanosheets

A layered bimetallic and hydroxide technology, applied in the direction of alumina/aluminum hydroxide, nanotechnology, nanotechnology, etc., to achieve the effects of low cost, simple preparation process, and reusable solvents

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The preparation method of the two-dimensional single-layer magnesium-aluminum layered double hydroxide nanosheet comprises the following steps:

[0038] a) After mixing the magnesium salt, aluminum salt and formamide, perform ultrasonic vibration until the mixture becomes a transparent solution to form solution A, wherein the molar ratio of magnesium ions in the magnesium salt to aluminum ions in the aluminum salt is 2:1; It is preferably at least one of magnesium nitrate, magnesium chloride and magnesium sulfate; the aluminum salt includes: at least one of aluminum nitrate, aluminum chloride and aluminum sulfate; and the ratio of the volume of formamide to the molar number of aluminum in the aluminum salt is (2~8)L / mol.

[0039] Since commercially available magnesium nitrate and aluminum nitrate generally have crystal water, magnesium nitrate is preferably magnesium nitrate hexahydrate {Mg(NO 3 ) 2 ·6H 2 O}, aluminum nitrate is preferably aluminum nitrate nonahydrat...

Embodiment 1

[0053] Because commercially available aluminum nitrate and magnesium nitrate are generally with crystal water, therefore, present embodiment uses commercially available magnesium nitrate hexahydrate {Mg(NO 3 ) 2 ·6H 2 O} and aluminum nitrate nonahydrate {Al(NO 3 ) 3 9H 2 O} as raw material to prepare two-dimensional single-layer magnesium-aluminum layered bimetallic hydroxide nanosheets.

[0054] It should be emphasized that whether aluminum nitrate and magnesium nitrate have water of crystallization has no influence on the present invention, so aluminum nitrate and magnesium nitrate without water of crystallization can also be used to realize the technical solution to be invented.

[0055] Concrete preparation process is as follows:

[0056] 2.05g (8mmol) Mg(NO 3 ) 2 ·6H 2 O and 1.50g (4mmol) Al(NO 3 ) 3 9H 2 O was dissolved in 15ml of formamide, and ultrasonically stirred until the solution was transparent to form solution A. Dissolve 1.92g (48mmol) NaOH in 35mL ...

Embodiment 2

[0058] 0.76g (8mmol) MgCl 2 and 0.53g (4mmol) AlCl 3 Dissolve in 8ml of formamide and stir ultrasonically until the solution becomes transparent to form solution A. According to the ratio of the amount of sodium hydroxide to aluminum ion being 9:1, 1.44g (36mmol) NaOH was gradually added to solution A, and stirred vigorously for 60min until it was completely dissolved to obtain a colloidal mixture. After the obtained colloidal mixed solution was centrifuged at a speed of 15000 rad / min for 3 min, the colloidal substance in the lower layer was redispersed in 40 mL of formamide and stirred until uniformly dispersed, then the dispersion was transferred to a 100 mL polytetrafluoroethylene reaction kettle, 20 ℃ for 72 hours to obtain a two-dimensional single-layer magnesium-aluminum layered double metal hydroxide nanosheet dispersion.

[0059] It should be noted that when obtaining the two-dimensional single-layer magnesium-aluminum layered double hydroxide nanosheet dispersion li...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com