Calcium-aluminum hydrotalcite and preparation method thereof

A calcium-aluminum hydrotalcite, calcium source technology, applied in chemical instruments and methods, aluminum compounds, aluminum carbonate compounds, etc. Problems such as low utilization of talc atoms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0025] The invention provides a preparation method of calcium aluminum hydrotalcite, comprising the following steps:

[0026] (1) mixing a calcium source, an aluminum source, a stabilizer and water to obtain a mixed material liquid, and reacting the mixed material liquid to obtain an intermediate slurry;

[0027] The anions in the mixture liquid contain OH - and a complex anion; the complex anion comprises Cl - , F - , SO 4 2- , NO 3 -, PO 4 3- and HPO 4 2- one or more of

[0028] (2) mixing the intermediate slurry with an alkaline salt solution for crystallization to obtain calcium-aluminum hydrotalcite.

[0029] In the present invention, unless otherwise specified, all components are commercially available products well known to those skilled in the art.

[0030] In the present invention, calcium source, aluminum source, stabilizer and water are mixed to obtain a mixed material liquid, and the mixed material liquid is reacted to obtain an intermediate slurry. In ...

Embodiment 1

[0042] Dissolve 236.2g of calcium nitrate tetrahydrate and 187.6g of aluminum nitrate nonahydrate in 1000mL of water to make a mixed salt solution, while dissolving 140g of sodium hydroxide and 87.6g of sodium chloride in 500mL of water to make a stabilizer solution, then Mix the mixed salt solution and the stabilizer solution, and react at 130° C. for 2 hours to obtain an intermediate slurry.

[0043] Dissolve 26.5g of anhydrous sodium carbonate in 500mL of water to obtain a sodium carbonate solution, then mix the intermediate slurry with the sodium carbonate solution, crystallize at 160°C for 14h, then cool to 80°C and filter, collect the obtained filtrate and return to Used for the preparation of the intermediate slurry, the obtained filter cake is dried at 60° C. and then pulverized to obtain calcium-aluminum hydrotalcite.

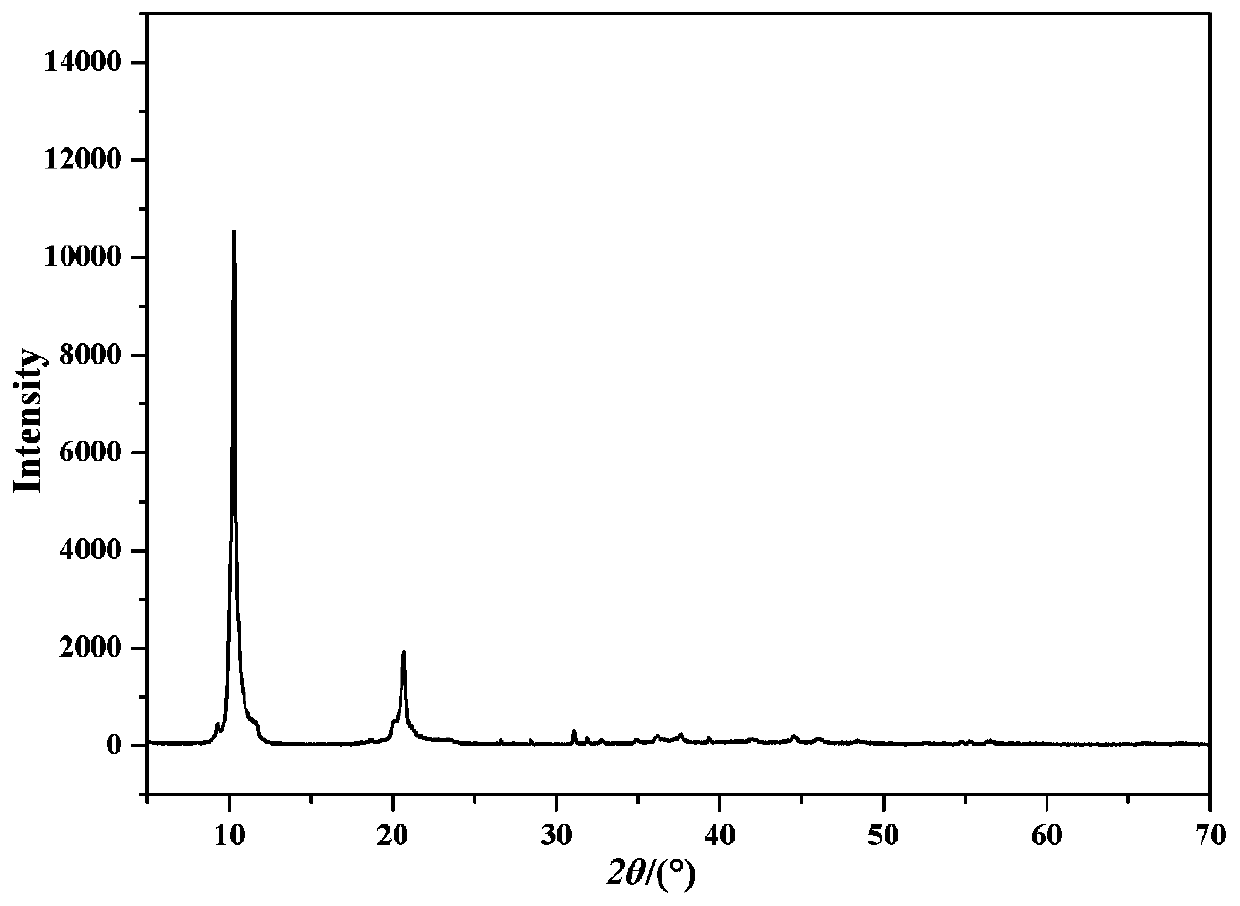

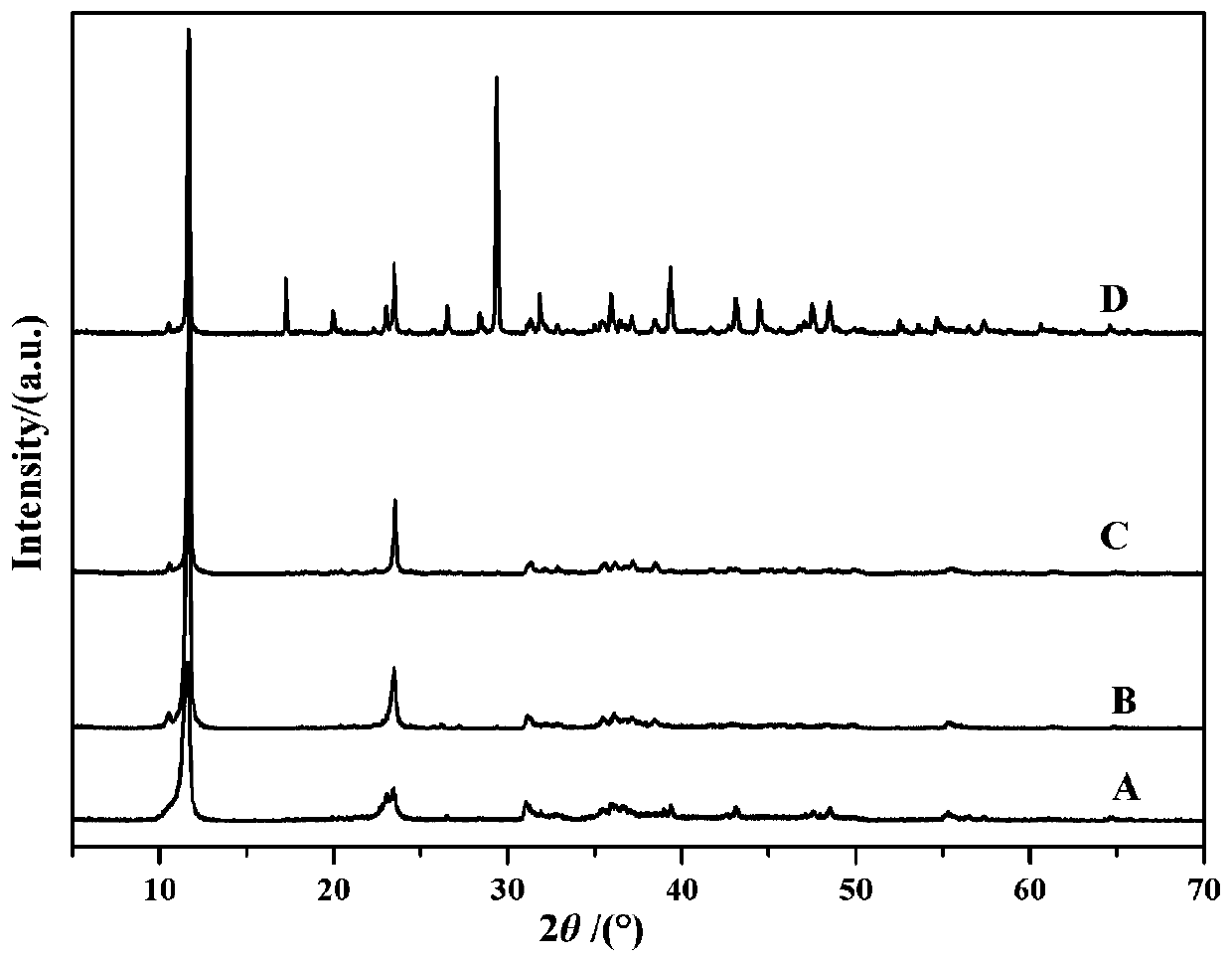

[0044] The intermediate slurry of Example 1 is filtered, dried and ground to obtain an intermediate solid substance, which is subjected to an XRD test...

Embodiment 2

[0046] 74g of calcium hydroxide and 39g of aluminum hydroxide were added to 1800mL of the filtrate recovered in Example 1. The anion concentration of the stabilizer in the filtrate was 2.72mol / L, and reacted at 110°C for 3h to obtain an intermediate slurry.

[0047] Dissolve 21g of sodium bicarbonate in 500mL of water to obtain a sodium bicarbonate solution, then mix the intermediate slurry with the sodium bicarbonate solution, crystallize at 140°C for 10h, then cool to 80°C and press filter to collect the resulting filtrate It is recovered and reused for the preparation of intermediate slurry, and the obtained filter cake is dried at 60° C. and then pulverized to obtain calcium-aluminum hydrotalcite.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com