Alumina recovery

一种氧化铝、氢氧化物的技术,应用在铝酸盐/氧化铝/氢氧化铝纯化、碱金属铝酸盐/氧化铝/氢氧化铝制备、无机化学等方向

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

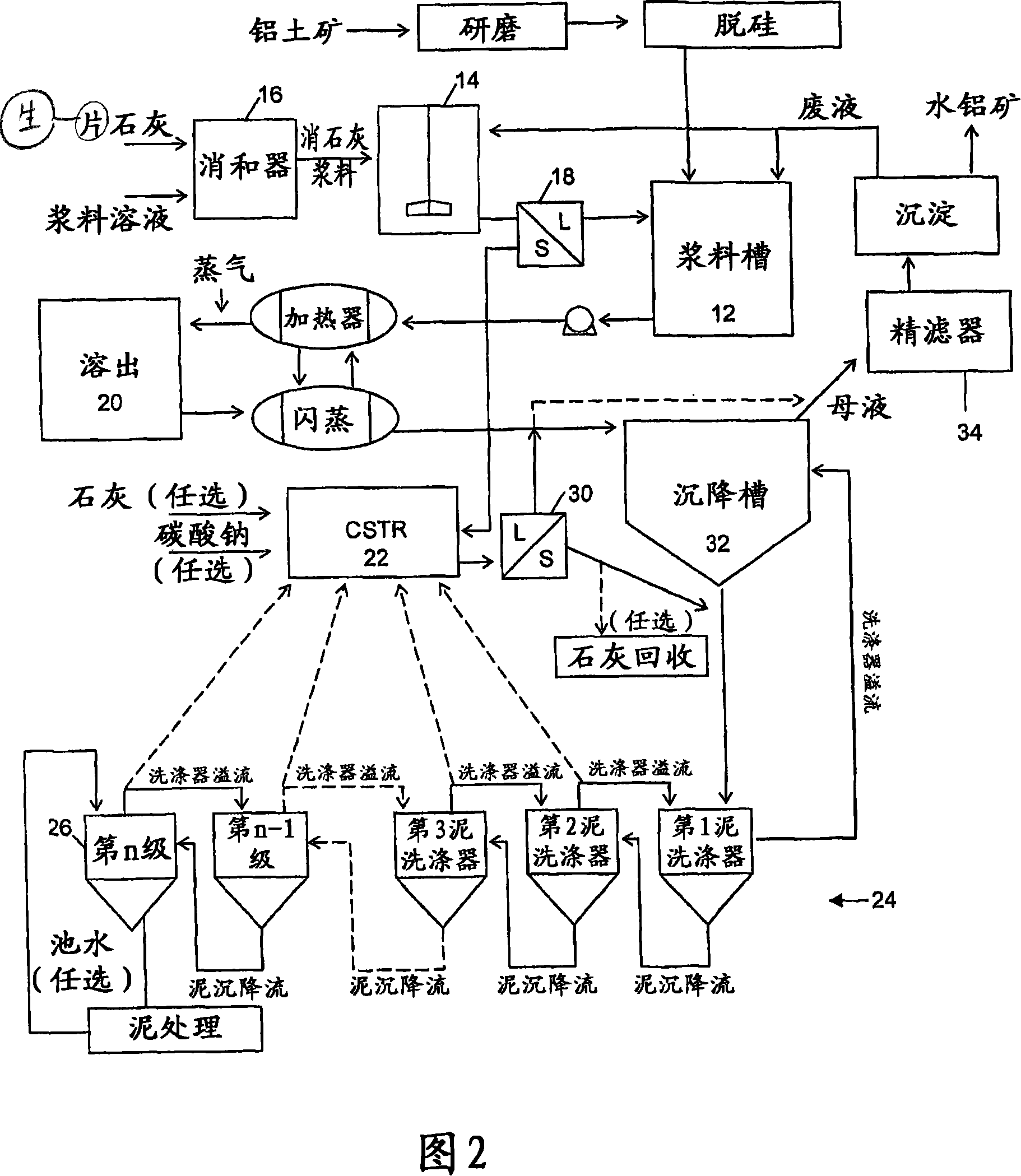

[0062] Example 1: Recovery of alumina from stripped feed

[0063] A first embodiment of the present invention is illustrated in the simplified process flow diagram of FIG. 2 . The bauxite is ground and desiliconized in the usual manner and then supplied to the slurry tank 12 for slurrying prior to dissolution. A effluent stream from the sedimentation is also fed to the slurry tank 12 using the conventional Bayer process. In this embodiment of the invention, the first liquid is transferred to reaction vessel 14 after precipitation in the form of all or part of the waste liquid stream. The stirring conditions within the reaction vessel 14 are not critical, but the contents of the reaction vessel 14 should preferably be completely suspended.

[0064] A slaked lime slurry is formed in the slaker 16 by adding quicklime and a slurry solution to the slaker 16 . This slaked lime slurry is then added to reaction vessel 14, where it reacts with the aluminate ions in the first liquid...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com