An intelligent aluminum magnesium carbonate crystallization system

A crystallization system, a technology of aluminum magnesium carbonate, applied in the field of aluminum magnesium carbonate production, can solve the problems of insufficient reaction, slow material reaction rate, poor stirring effect, etc., and achieve good stirring effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

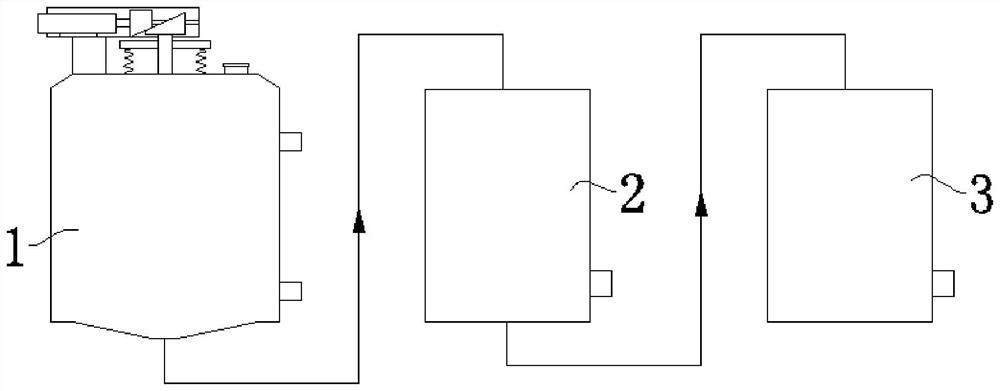

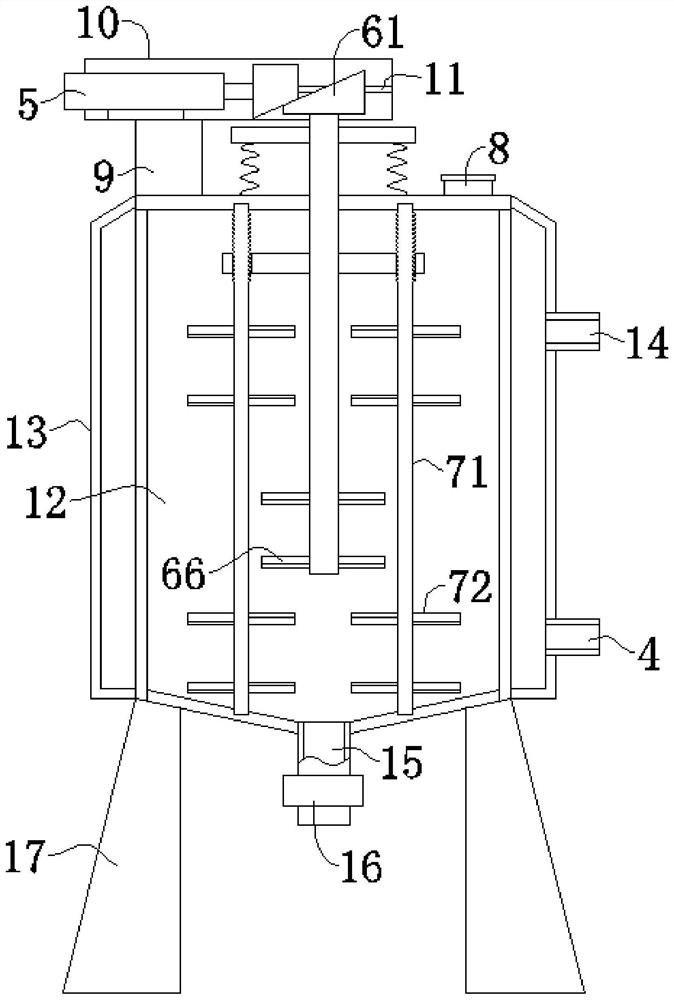

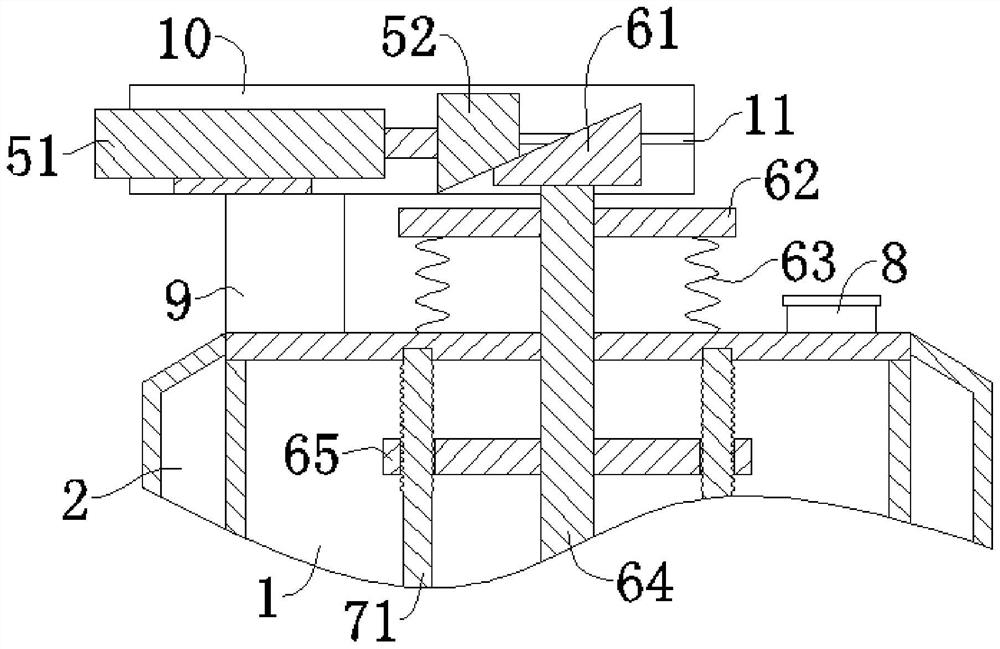

[0028] Example: an intelligent aluminum magnesium carbonate crystallization system, such as Figure 1-3 As shown, it includes a reactor 1, a filtering device 2 and a drying device 3 that are connected in sequence. The reaction kettle 1 includes a cylindrical kettle body 12 , a discharge port 15 is provided at the bottom of the kettle body 12 , and a valve 16 is installed at the discharge port 15 . The filtering device 2 is used to filter the material discharged from the outlet 15 of the reaction kettle 1, and the drying device 3 is used to dry the solid particles obtained after filtering by the filtering device 2 to obtain aluminum magnesium carbonate. The top side of the kettle body 12 is provided with a feeding port 8, and the outer surface of the kettle body 12 is covered with a jacket 13. The jacket 13 is provided with a heat medium inlet 4 and a heat medium outlet 14 for the heat medium to enter and exit. The heat medium can be Circulating hot water, circulating steam or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com