Preparation method for carbonate type hydrotalcite compound powder

A hydrotalcite and carbonate type technology, applied in aluminum carbonate compounds, hydrotalcite, nickel compounds, etc., can solve the problems of slow reaction speed, easy particle size growth, low solubility of raw materials, etc., and achieve accelerated reaction and crystal development. Complete, good dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

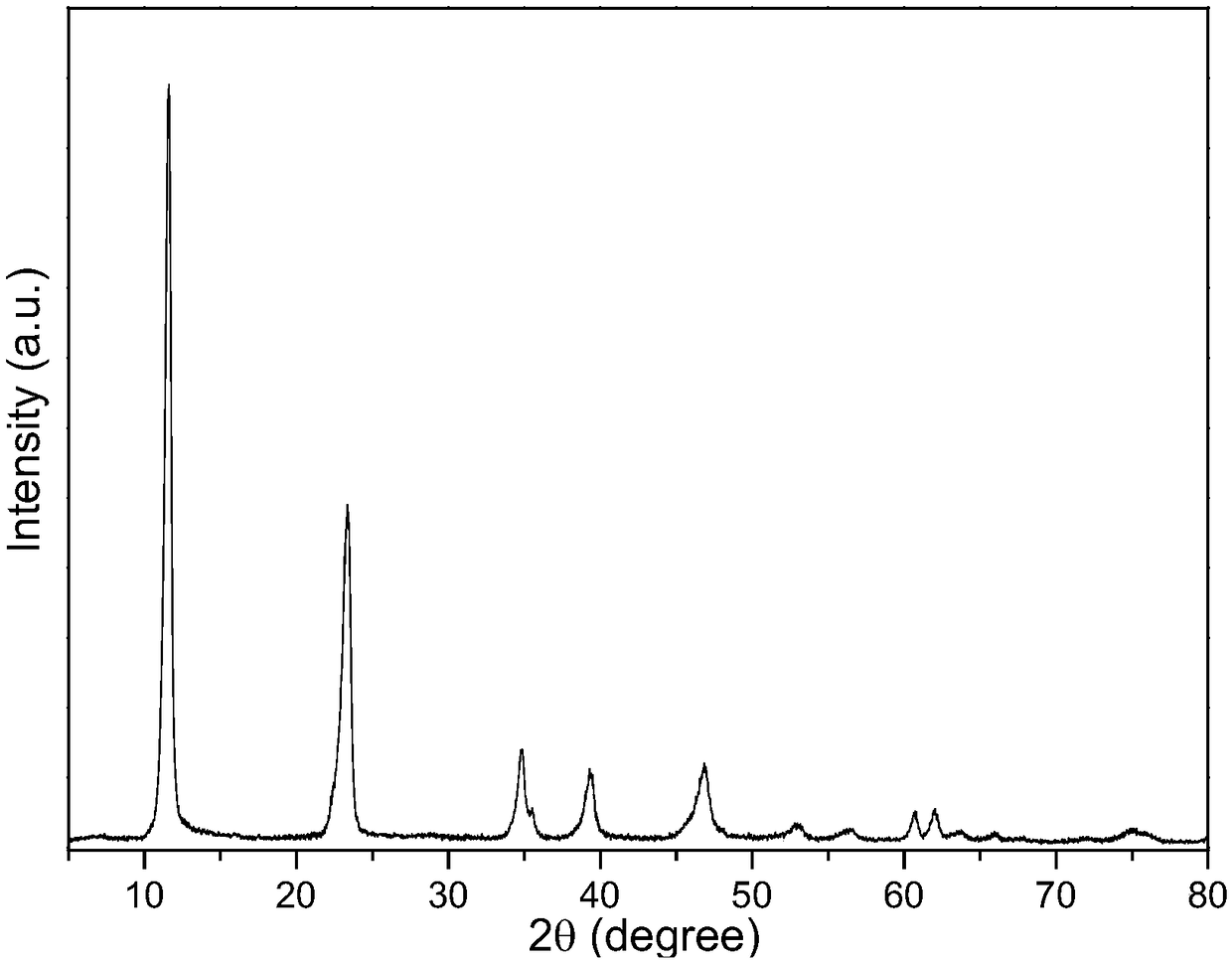

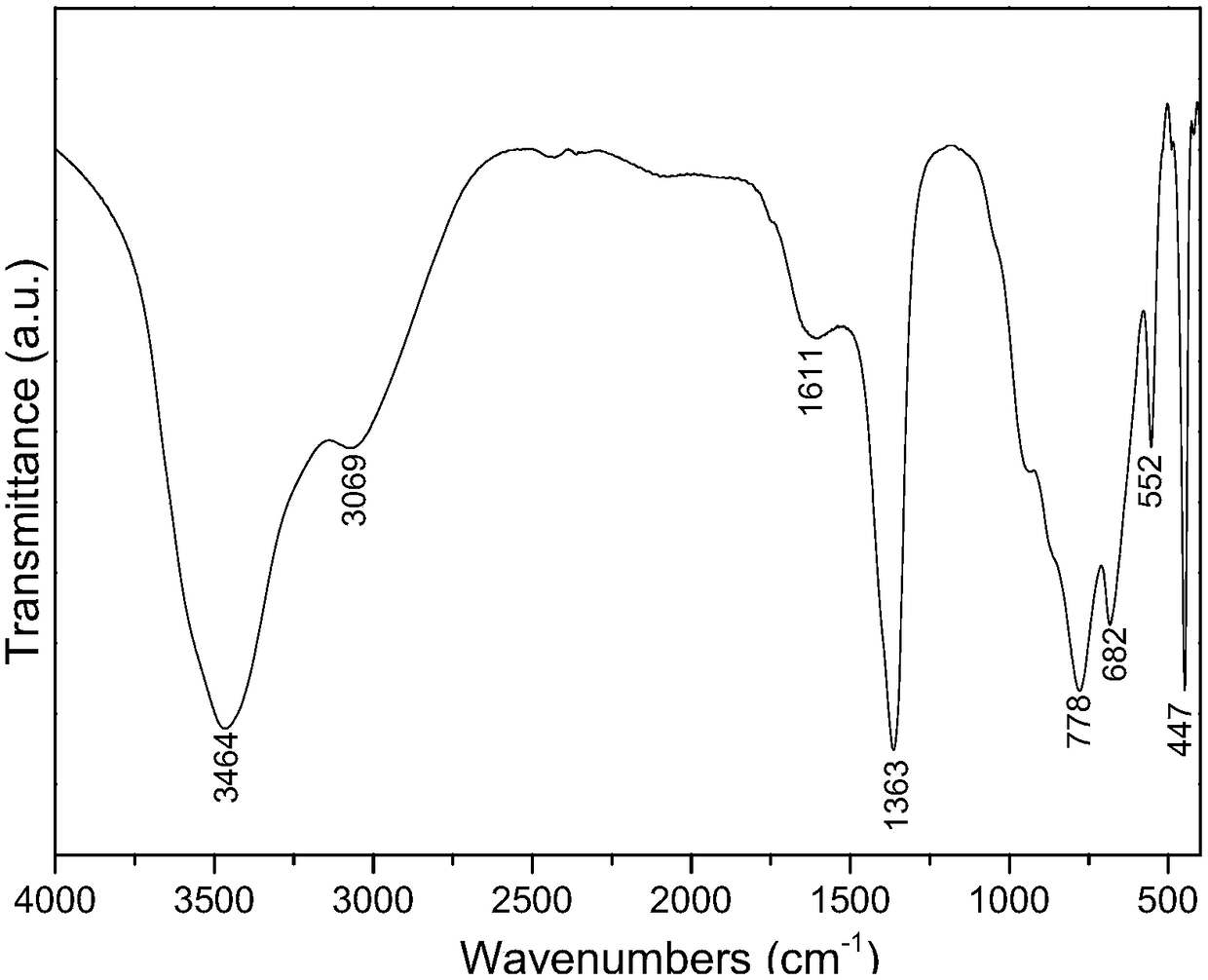

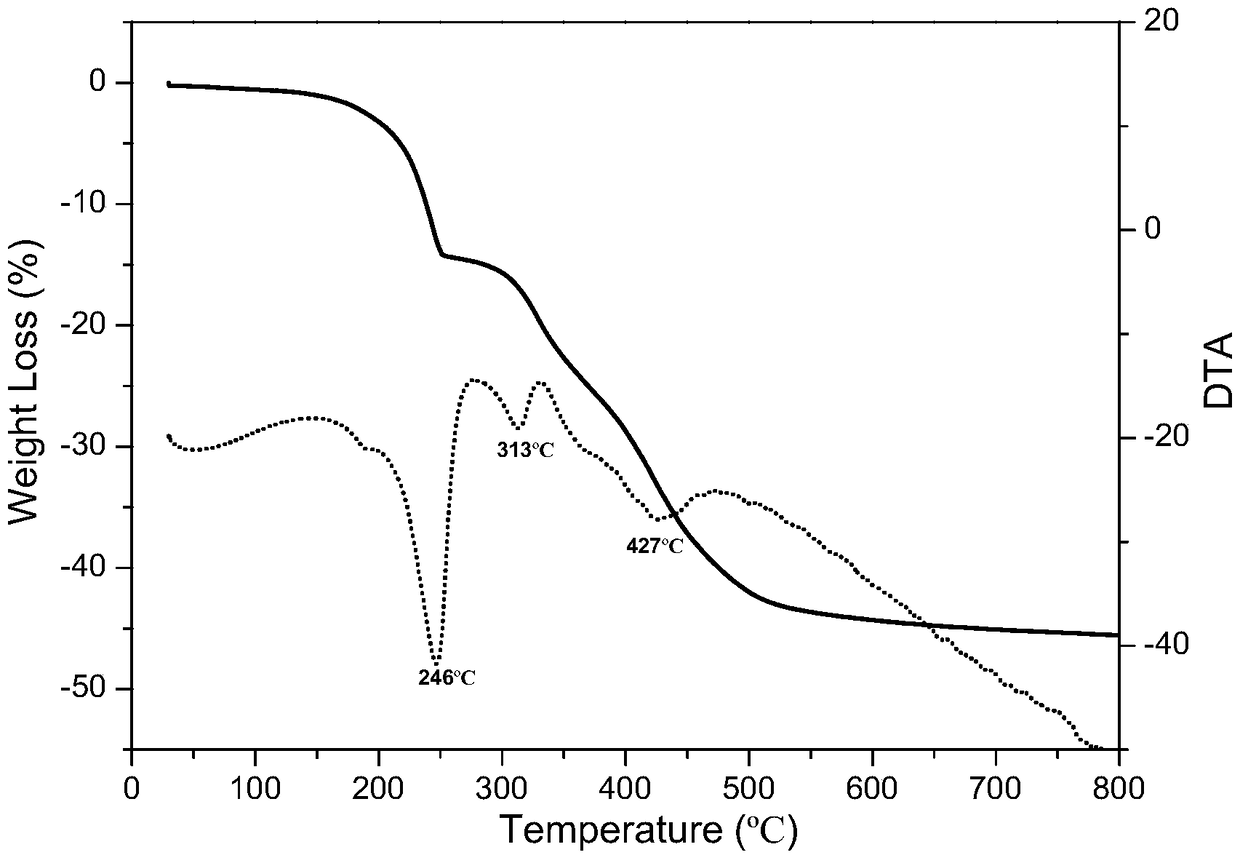

[0040] MgO, Al(OH) 3 , MgCO 3 ·Mg(OH) 2 ·H 2 O was mixed and added to a 1.2L reaction kettle at a molar ratio of 7:4:3, and 975mL of deionized water was added with a solid content of 7.5wt%. After stirring evenly, the temperature was raised to 165°C, and ultrasonically After hydrothermal reaction for 1h, after cooling, the product was separated from solid and liquid and dried to obtain MgAl-CO 3 2- -LDHs powder. By XRD results such as figure 1 As shown, the peak shape of each characteristic diffraction peak is sharp, the baseline is smooth, and there is no impurity peak, indicating that the product has a single crystal phase and good crystallinity. Utilize infrared spectrum to carry out qualitative analysis to this sample, the result is as follows figure 2 As shown, 3464cm -1 The absorption peak at is due to the stretching vibration of hydroxyl groups on the laminate. 3069cm -1 The absorption peak at is caused by the interlayer CO 3 2- Due to hydrogen bonding with...

Embodiment 2

[0044] Mg(OH) 2 , Al(OH) 3 , MgCO 3 ·Mg(OH) 2 ·H 2 O was mixed and added to a 1.2L reactor at a molar ratio of 4:2:1, and 975mL of deionized water was added with a solid content of 5wt%. After stirring evenly, the temperature was raised to 120°C, and ultrasonic hydrothermal heating was carried out at an ultrasonic power of 1200W. After reacting for 0.5h, after cooling, the product was separated from solid and liquid and dried to obtain MgAl-CO 3 2- -LDHs powder. The average particle size D of the product 50 = 1.81 μm (P[X] = 85.3%), the agglomeration index was 3.5.

Embodiment 3

[0046] Ca(OH) 2 , Al(OH) 3 , CaCO 3 Mix them into a 1.2L reactor according to the molar ratio of 28:11:2, add 975mL of deionized water with a solid content of 20wt%, stir evenly, heat up to 200°C, and perform ultrasonic hydrothermal reaction at 500W ultrasonic power 8h, after cooling, the product was separated from solid and liquid and dried to obtain CaAl-CO 3 2- -LDHs powder, the average particle size of the product D 50 = 3.67 μm (P[X] = 78%), the agglomeration index was 4.1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com