Method for preparing PVC heat stabilizer by taking vermiculite as raw material

A heat stabilizer and vermiculite technology, applied in chemical instruments and methods, ultra-high pressure application processes, inorganic chemistry, etc., can solve the problems of slow environmental protection process, uneven product quality, and insufficient original product innovation , to achieve the effects of easy promotion, small energy loss, obvious economic and social benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

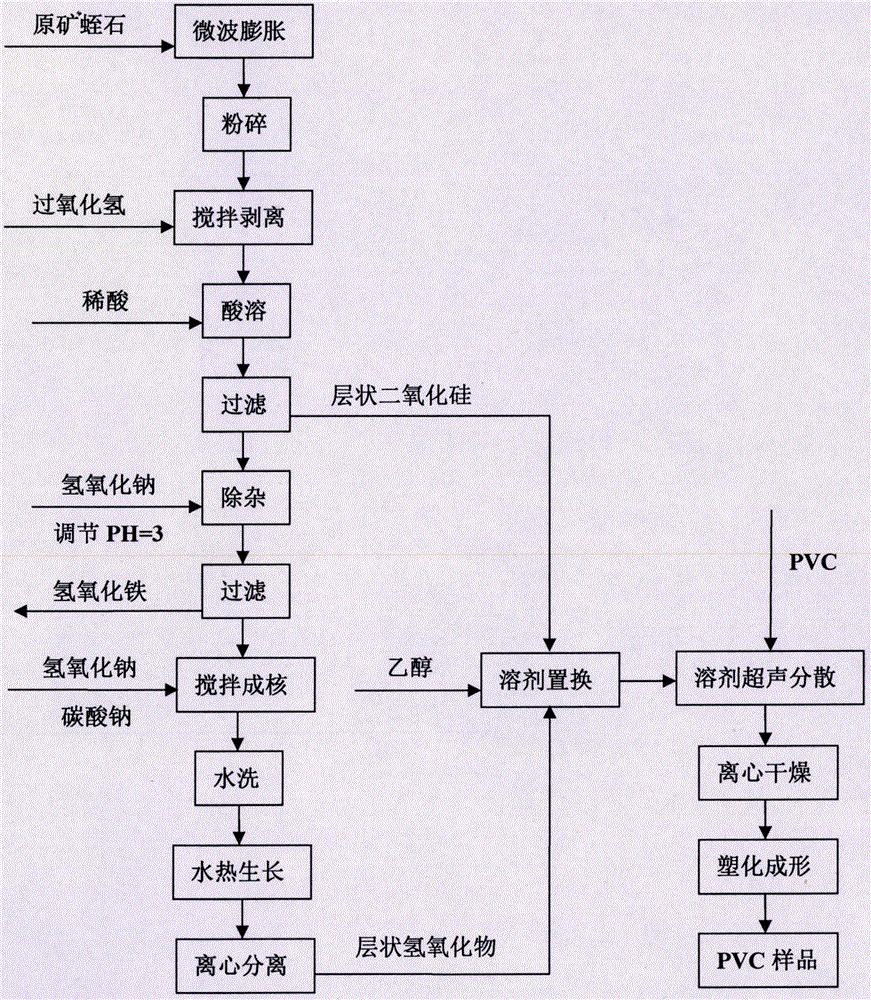

Method used

Image

Examples

Embodiment 1

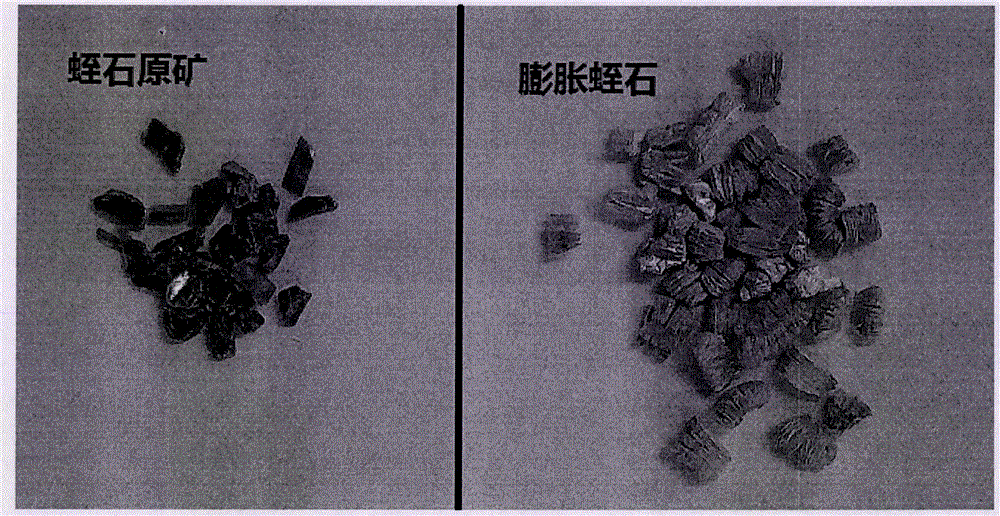

[0034] Take 5 grams of raw vermiculite, crush it to 10 meshes, and expand it under a microwave power of 1500W for 60 seconds to prepare expanded vermiculite. Expanded vermiculite is crushed to 120 mesh, put into 30% hydrogen peroxide solution by weight, stirred and peeled at 80℃, after stirring and peeling for 5 days, adjust the PH value to 1 by adding 0.1mol / L hydrochloric acid, and then at 80 After heating at ℃ for 3.5 hours, centrifugal separation obtains supernatant and solid. The solid is washed to become silica heat stabilizer.

[0035] The supernatant obtained above was adjusted to pH 3 with 0.1 mol / L sodium hydroxide solution, heated at 80°C to flocculate, and filtered to remove the red solid iron hydroxide to obtain the filtrate; in the beaker, put the machine Stir the paddle, adjust the stirring speed to 4000rpm, and gradually pour the 1:1 filtrate and the mixed solution of sodium hydroxide and sodium carbonate (mass concentration of 0.1mol / L sodium hydroxide and 0.05mo...

Embodiment 2

[0040] Take 5 grams of raw vermiculite, crush it to 20 meshes, and expand it under a microwave power of 1200W for 60 seconds to prepare expanded vermiculite. Expanded vermiculite was crushed to 150 mesh, put into 30% hydrogen peroxide solution by weight, stirred and peeled at 80℃, after stirring and peeling for 4 days, adjust the PH value to 1 by adding 0.1mol / L hydrochloric acid, and then at 80 After heating at ℃ for 3 hours, centrifuged to obtain supernatant and solids. The solids are washed to become silica heat stabilizers.

[0041] The supernatant obtained above was adjusted to pH 3 with 0.1 mol / L sodium hydroxide solution, heated at 80°C to flocculate, and filtered to remove the red solid iron hydroxide to obtain the filtrate; in the beaker, put the machine Stir the paddle, adjust the stirring speed to 3500rpm, and gradually pour the 1:1 filtrate and the mixed solution of sodium hydroxide and sodium carbonate (mass concentration of 0.1mol / L sodium hydroxide and 0.05mol / L so...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com