Method for preparing bar-shaped ammonium aluminum carbonate without template agent

An ammonium aluminum carbonate, template-free technology, applied in aluminum carbonate compounds, chemical instruments and methods, inorganic chemistry and other directions, can solve the problems of high preparation cost, complex preparation process, environmental pollution, etc., and achieves simple preparation method and simplified preparation. Process and environment-friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

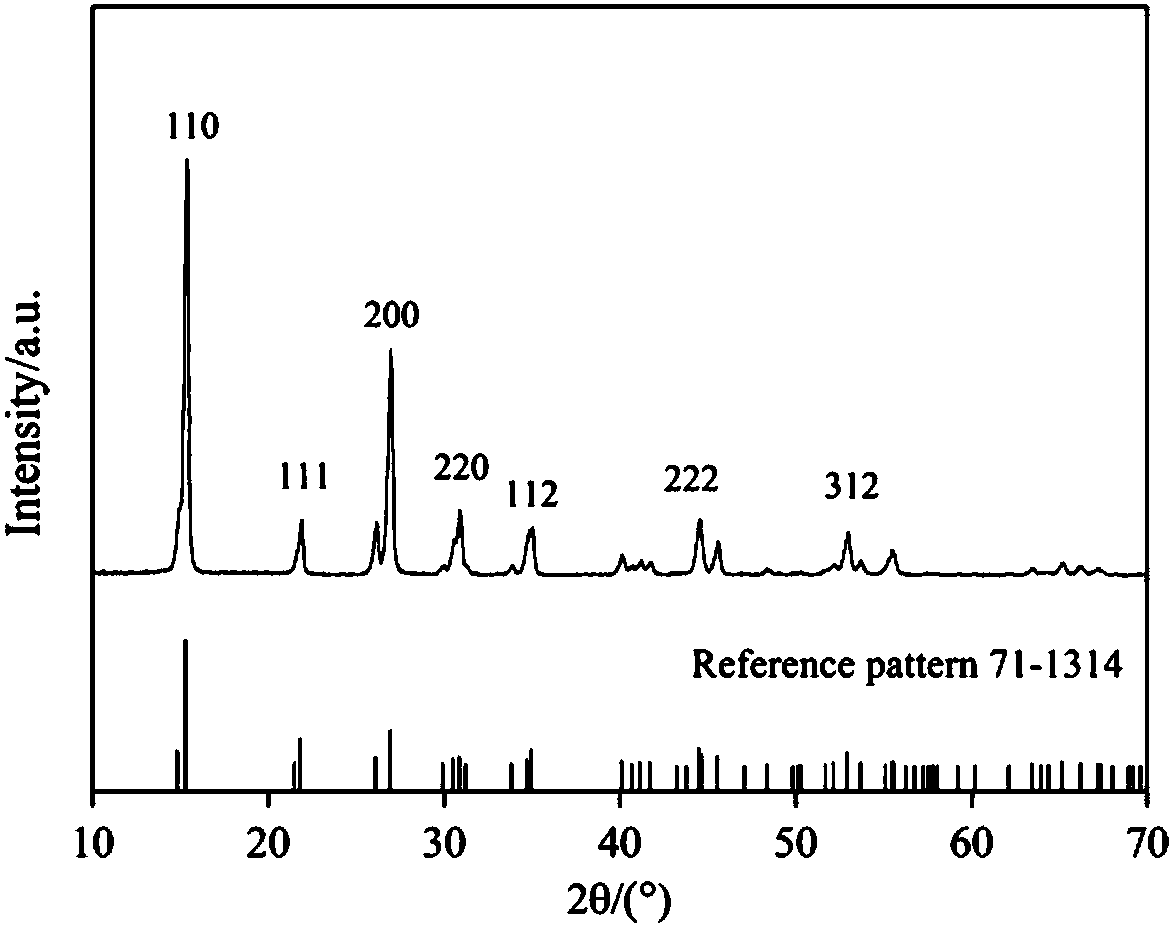

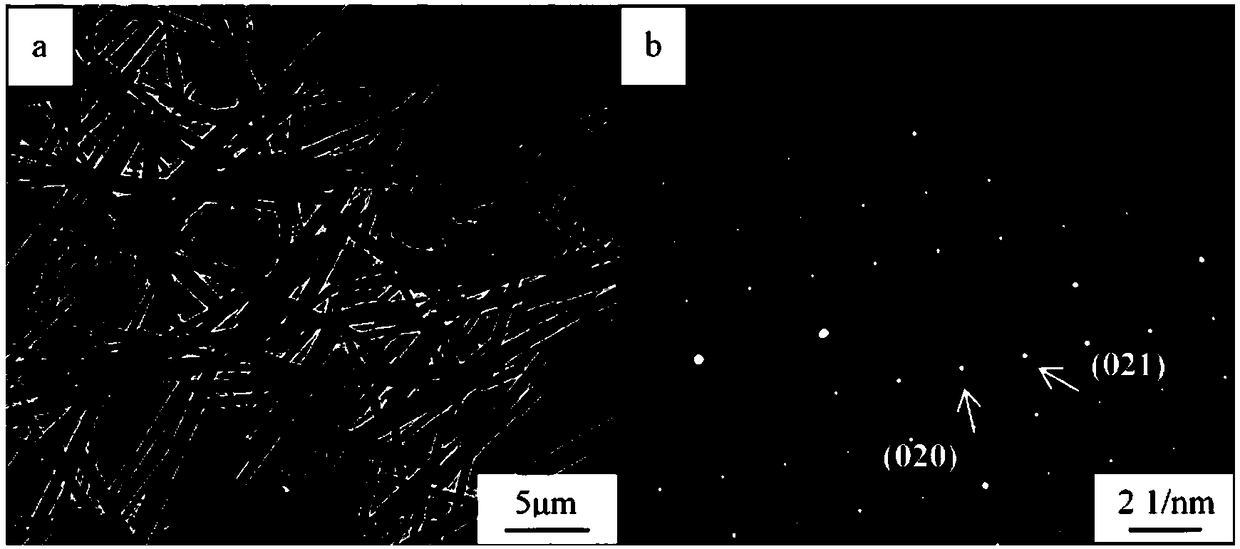

[0032] In this embodiment, a method for preparing rod-shaped ammonium aluminum carbonate without a template is to use aluminum nitrate as the aluminum source and urea as the precipitating agent to synthesize rod-shaped ammonium aluminum carbonate by hydrothermal method.

[0033] A kind of preparation rod aluminum ammonium carbonate without template, its preparation process is specifically as follows:

[0034] Weigh 4g of aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 9.6g urea (n 硝酸铝 :n 尿素 =1:15) was dissolved in 20mL of distilled water, and the mixed solution was stirred for 30 minutes, so that the reactant was fully dissolved to obtain a reaction mixed solution, and then the gained reaction mixture solution was transferred to a high-pressure hydrothermal reaction kettle, and the high-pressure hydrothermal reaction The kettle was sealed and reacted in an oven at 180°C for 12 hours, then the high-pressure hydrothermal reaction kettle was naturally cooled to room temperature, fi...

Embodiment 2

[0036] A kind of preparation rod aluminum ammonium carbonate without template, its preparation process is specifically as follows:

[0037] Weigh 4g of aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 8.32g urea (n 硝酸铝 :n 尿素 =1:13) was dissolved in 20mL of distilled water, and the mixed solution was stirred for 30 minutes so that the reactants were fully dissolved to obtain a reaction mixed solution, then the resulting reaction mixture solution was transferred to a high-pressure hydrothermal reaction kettle, and the high-pressure hydrothermal reaction The kettle was sealed and reacted in an oven at 160°C for 16 hours, then the high-pressure hydrothermal reactor was naturally cooled to room temperature, filtered and the precipitate was retained, and the product was repeatedly washed with absolute ethanol and distilled water to remove the reaction by-products, and the resulting solid product was Dry it in a vacuum oven at 70°C for 12 hours, and naturally cool to room temperature to...

Embodiment 3

[0039] A kind of preparation rod aluminum ammonium carbonate without template, its preparation process is specifically as follows:

[0040] Weigh 4g of aluminum nitrate (Al(NO 3 ) 3 9H 2 O) and 11.52g urea (n 硝酸铝 :n 尿素 =1:18) was dissolved in 20mL of distilled water, and the mixed solution was stirred for 60 minutes so that the reactant was fully dissolved to obtain a reaction mixed solution, and then the gained reaction mixture solution was transferred to a high-pressure hydrothermal reaction kettle, and the high-pressure hydrothermal reaction The kettle was sealed and reacted in an oven at 200°C for 8 hours, then the high-pressure hydrothermal reactor was naturally cooled to room temperature, filtered and the precipitate was retained, and the product was repeatedly washed with absolute ethanol and distilled water to remove the reaction by-products, and the obtained solid product was Dry it in a vacuum oven at 80°C for 20 hours, and naturally cool to room temperature to o...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com