Green technology for synthesizing ammonium aluminum carbonate hydroxide and pyrolysis thereof to prepare high specific surface alumina

A technology of aluminum ammonium carbonate and green technology, which is applied in the fields of aluminum carbonate compound, alumina/hydroxide preparation, inorganic chemistry, etc., can solve the problems of excessive waste liquid and failure to realize waste liquid recycling, and achieve no waste liquid discharge , reduce emissions and reduce energy consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

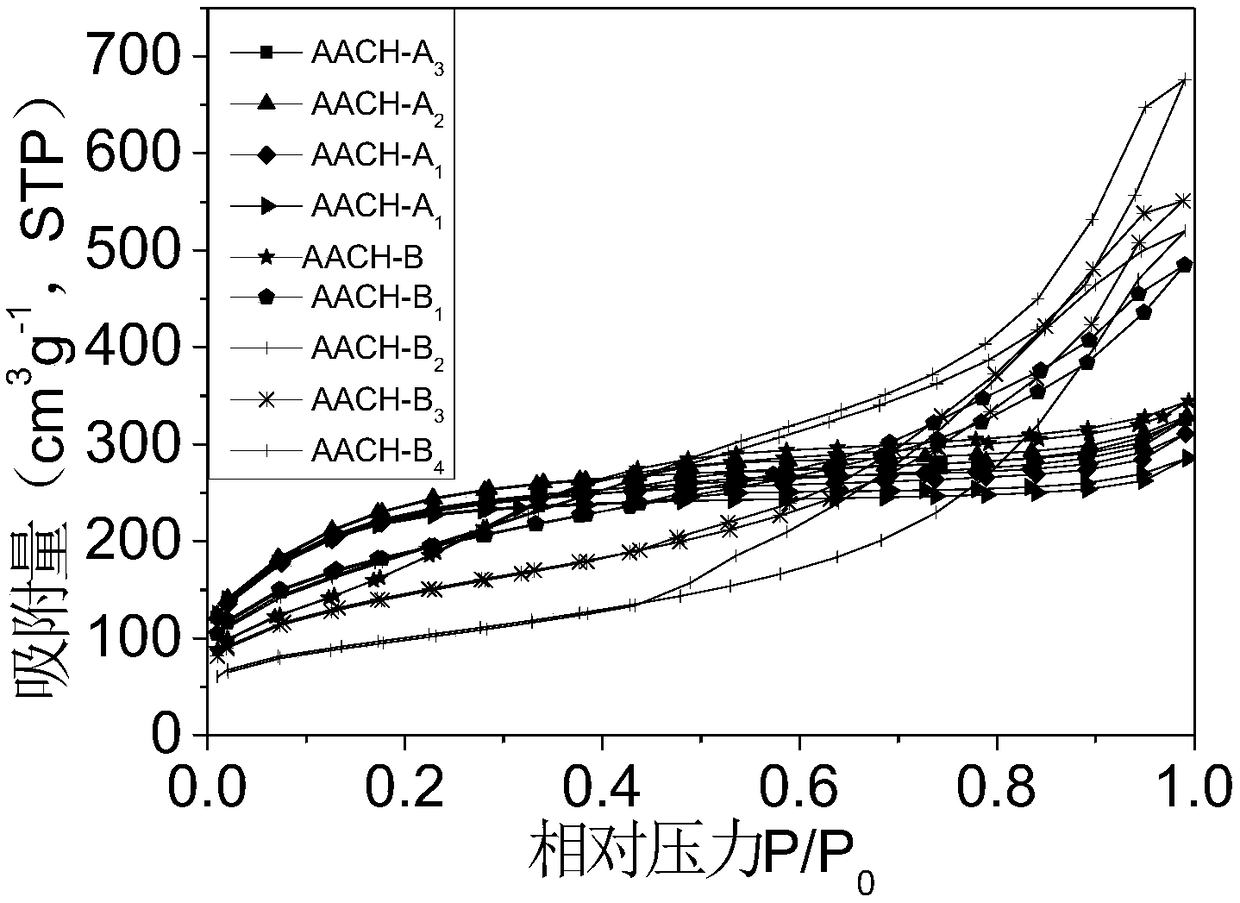

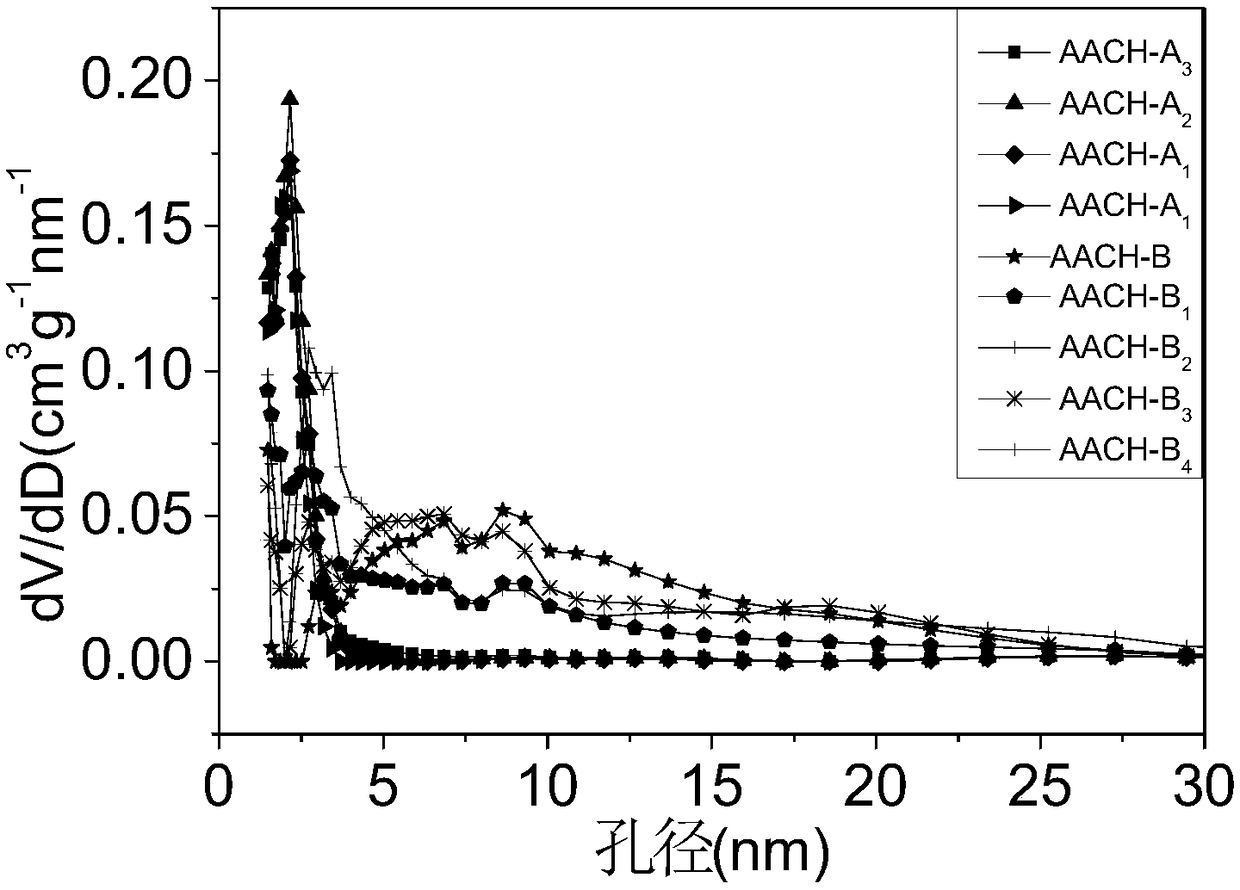

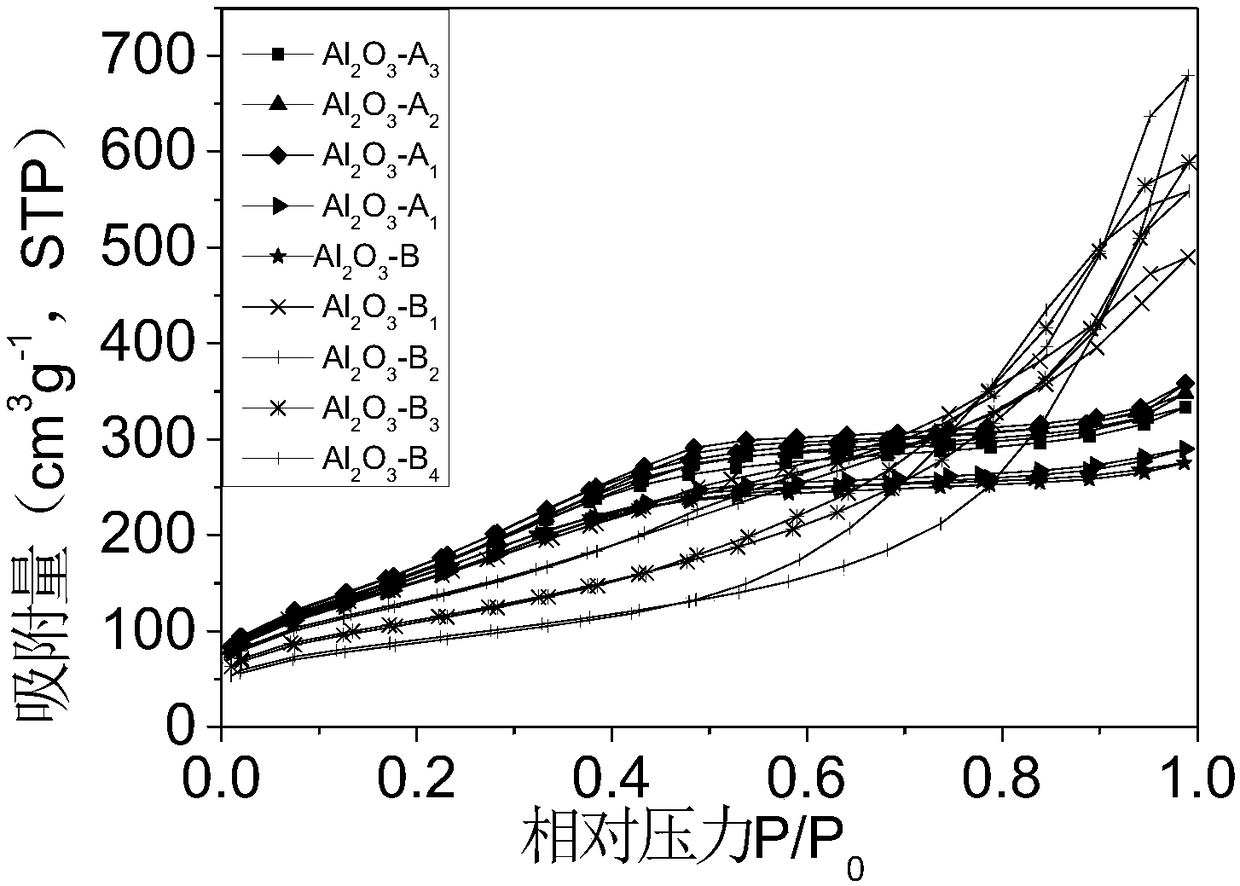

[0020] Example 1: At room temperature, prepare an ammonium carbonate solution with a concentration of 10.5 mol / L, then add a certain amount of pseudo-boehmite according to the molar ratio of ammonium carbonate to Al of 15, and stir for 30 minutes until the solution is uniform. Transfer the uniform turbid liquid into a crystallization kettle for crystallization at 100°C for 24 hours, filter and wash the crystallized solid, and dry it at 100°C for 12 hours to obtain ammonium aluminum carbonate, which is designated as AACH-A. The resulting liquid is marked as mother liquor (1). The obtained AACH-A specific surface area is 732.7m 2 g, total pore volume 0.4cm 3 g, the average pore diameter is 2.4nm. The resulting AACH-A in N 2 In the atmosphere, the temperature was raised to 300°C at a rate of 2°C / min, and then roasted at a constant temperature for 2 hours, and then the temperature was raised to 500°C in a muffle furnace at a rate of 2°C / min, and roasted at a constant temperatur...

Embodiment 2

[0024] Example 2: At room temperature, prepare a urea solution with a concentration of 10.5 mol / L, then add a certain amount of pseudo-boehmite according to the molar ratio of urea to Al of 15, and stir for 30 minutes until the solution is uniform. Transfer the uniform turbid liquid into a crystallization kettle for crystallization at 100°C for 24 hours, filter and wash the crystallized solid, and dry it at 100°C for 12 hours to obtain ammonium aluminum carbonate, which is designated as AACH-B. The resulting liquid is marked as mother liquor ①. The obtained AACH-B specific surface area is 724.6m 2 g, total pore volume 0.4cm 3 g, the average pore diameter is 2.4nm. The resulting AACH-B in N 2 In the atmosphere, the temperature was raised to 300°C at a rate of 2°C / min, and then roasted at a constant temperature for 2 hours, and then the temperature was raised to 500°C in a muffle furnace at a rate of 2°C / min, and roasted at a constant temperature for 3 hours, the obtained Al ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Specific surface area | aaaaa | aaaaa |

| Pore volume | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com