Prepn of doped magnetic ferrite material

A magnetic material and ferrite technology, which is applied in the field of preparation of doped ferrite magnetic materials, can solve the problems of difficult precise control of doping amount, long relative sintering time, high sintering phase temperature, etc., to shorten the production cycle, Shorter sintering time and better repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0016] Embodiment one: take by weighing Ni(NO) that chemical purity is 98% 3 ) 2 ·6H 2 O 112.66 g, Zn with a purity of 99% (NO 3 ) 2 ·6H 2 O 76.06 g, Fe(NO 3 ) 3 9H 2 O 521.76 g, 99% pure C 6 h 8 o 7 ·H 2 O 400.89 grams and the salt Co(NO 3 )·6H 2 O appropriate amount; use 354ml of deionized water to configure an aqueous solution respectively. Fix the wide-mouth cup in the thermostat, and control the temperature at the best 60°C. Slowly pour the prepared solution into the wide-mouth cup in sequence, and stir at constant temperature for about 60 minutes. While stirring, use a dropper Add ethylenediamine dropwise to adjust the pH value of the solution to 5-7. At this time, the wet gel solution turns dark green. Put the prepared wet gel solution directly on the electric furnace for evaporation, remove most of the water, put the gel in the sintering furnace, and pre-fire at 500°C for 15 minutes as needed. At this point, the gel turns into a reddish-brown fluffy pow...

Embodiment 2

[0017] Embodiment 2: The preparation method is the same as that of Embodiment 1, except that copper nitrate is used for doping with metal nitrate, and the sintering temperature is 1100°C.

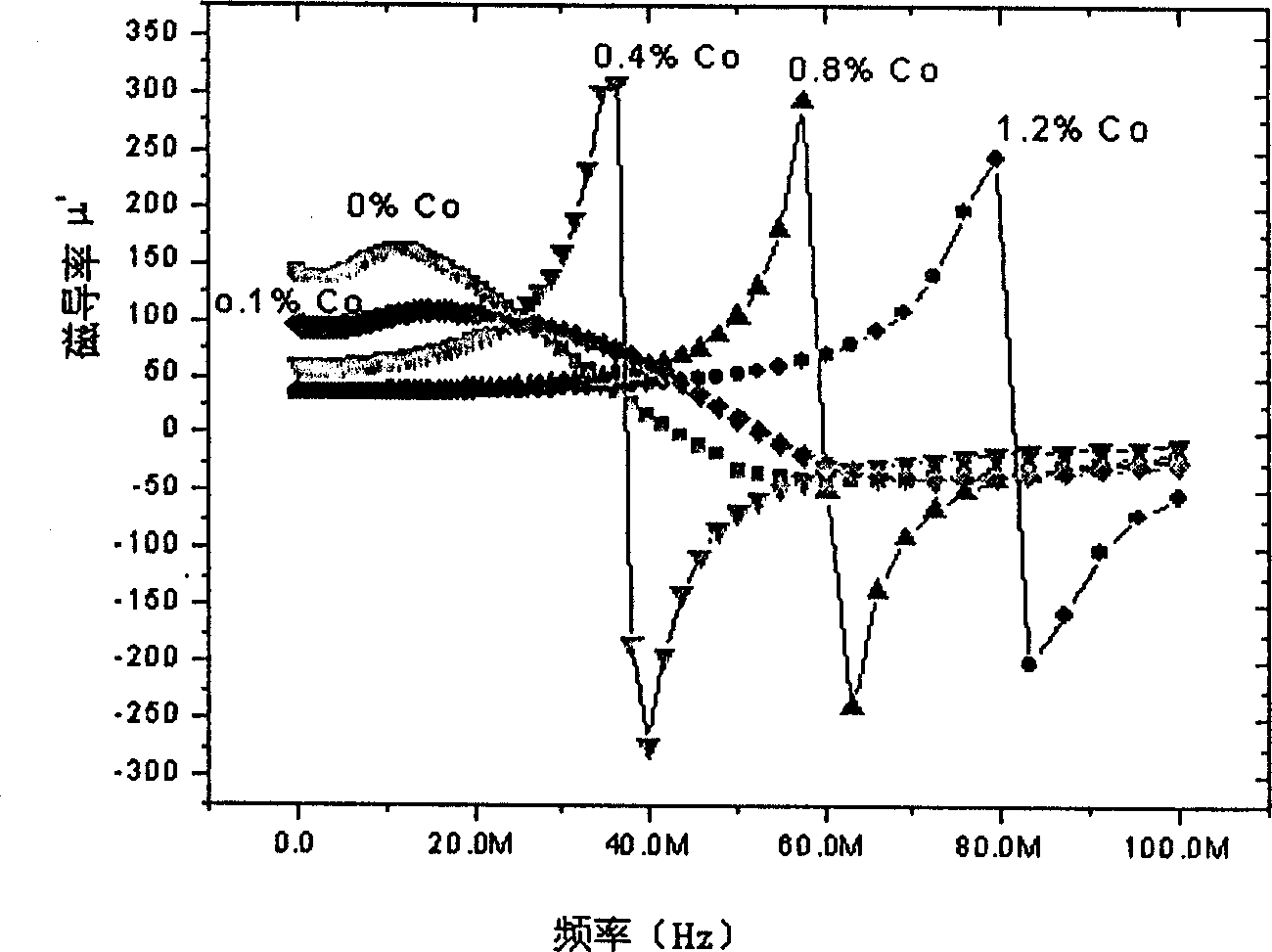

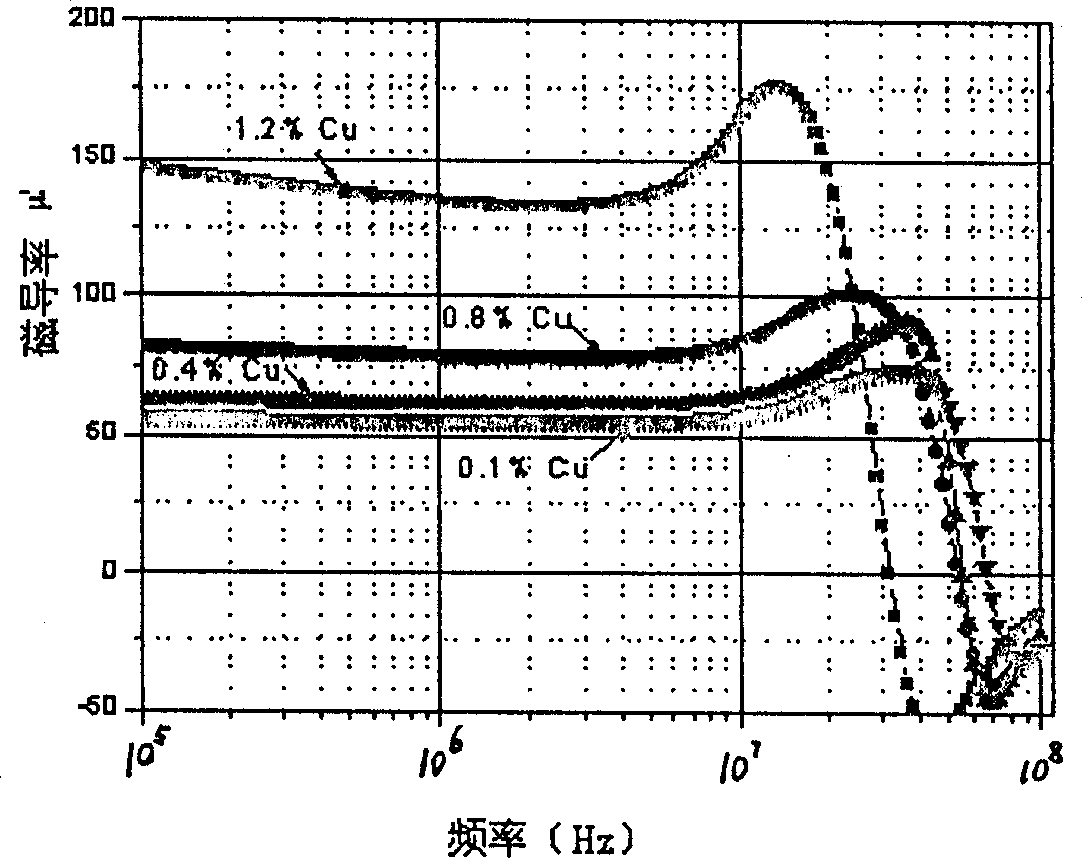

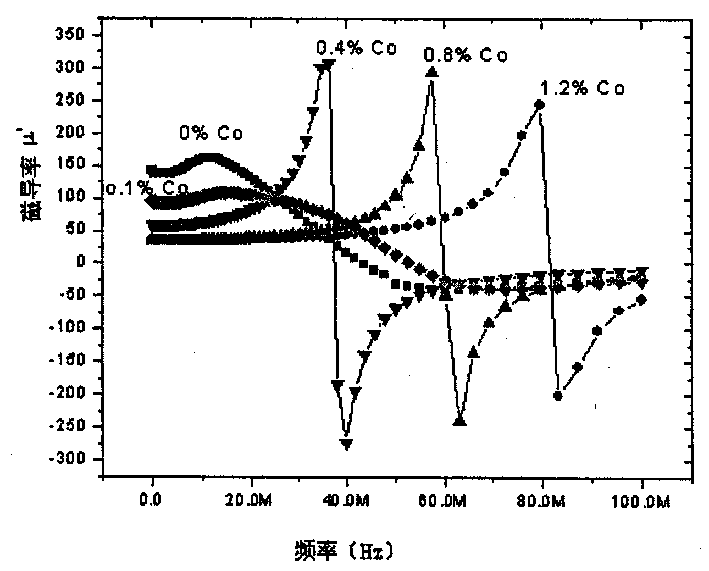

[0018] According to the magnetic spectrum of the different cobalt-doped and copper-doped ferrite magnetic materials prepared by the inventive method, see figure 1 and figure 2 . From figure 1 and figure 2 It can be seen from the figure that, for the doped ferrite magnetic material prepared by the method of the present invention, the influence of the slight change of the dopant on the electromagnetic properties of the final sample can be detected and controlled, and the process is stable, easy to repeat, and the performance Stablize.

[0019] The method of the invention is not only applicable to the doping of various soluble salt solutions of alkaline earth metals, main metals, transition metals, nonmetals and rare earth elements, but also can be used for mixed doping of two or more el...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com