Preparation method of lithium ion battery negative electrode material spinel porous high-entropy oxide material

A lithium-ion battery and negative electrode material technology, applied in battery electrodes, chemical instruments and methods, negative electrodes, etc., to achieve the effects of high dispersion, fine particle size, and fast combustion synthesis speed

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

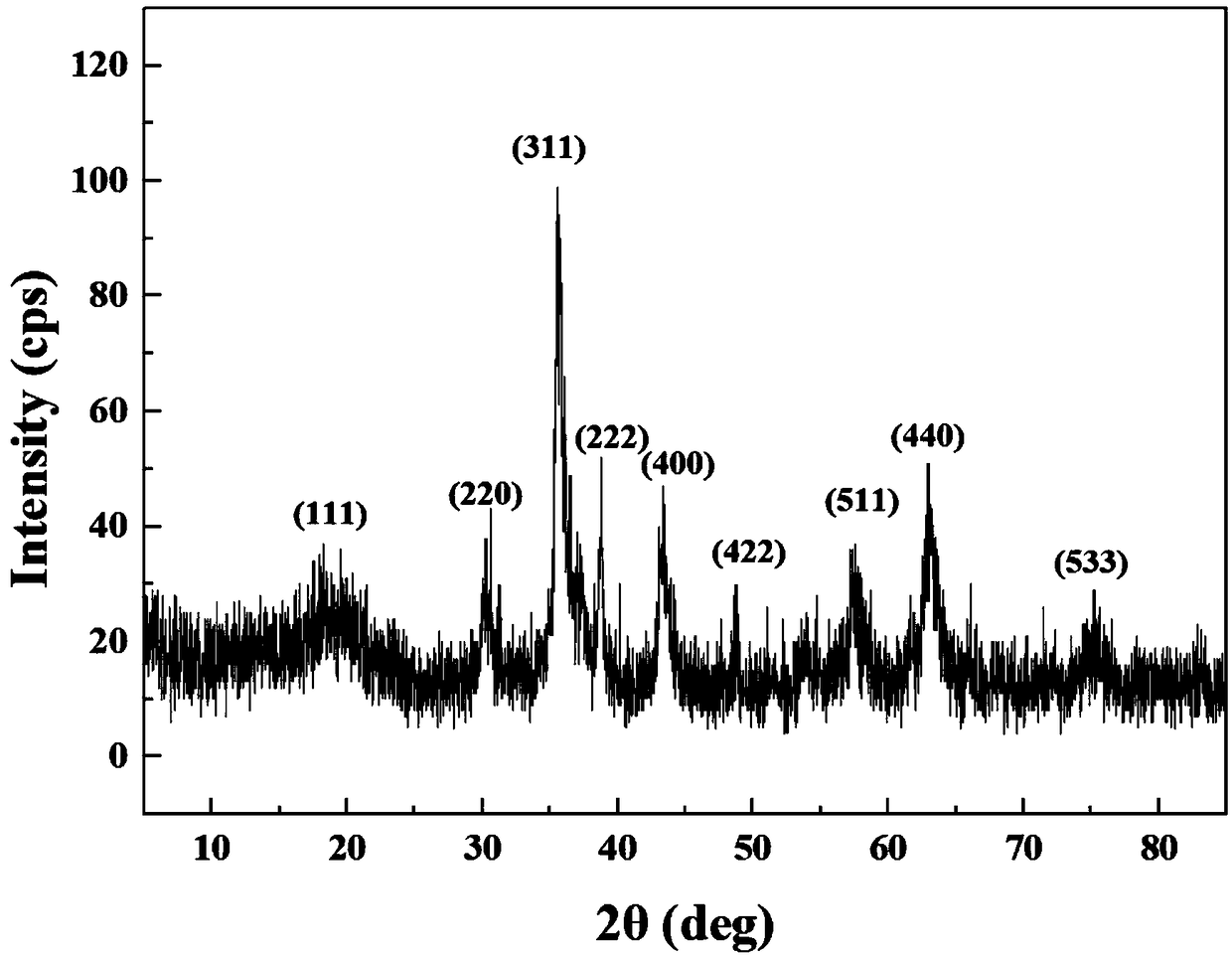

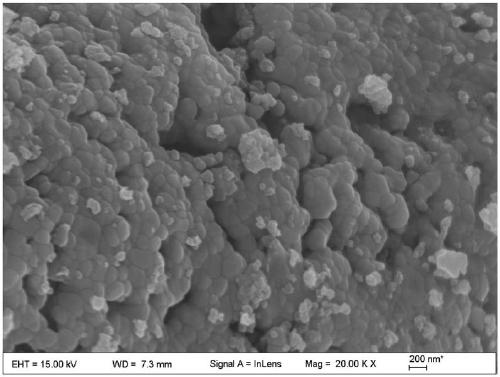

[0023] Weigh 29.01g of Co(NO 3 ) 2 ·6H 2 O, 40.02g of Cr(NO 3 ) 3 9H 2 O, 24.16g of Cu(NO 3 ) 2 ·3H 2 O, 40.4g of Fe(NO 3 ) 3 9H 2 O and 29.08g of Ni(NO 3 ) 2 ·6H 2O was dissolved in 50mL of distilled water and 50mL of ethanol solution, and stirred evenly to obtain a mixed solution containing metal salts; then 38.42g of citric acid and 54.05g of glucose were weighed and added to the above mixed solution, and after stirring evenly, the pH of the mixed solution was adjusted with ammonia water. 8. Obtain a transparent sol; then heat the above transparent sol in an oil bath at 160°C to remove the solvent water to obtain a loose, foamy gel; finally place the above gel in a muffle furnace at 250°C for 30 minutes , to get the final product. XRD spectrum ( figure 1 ) shows that the prepared (CoCrCuFeNi) 3 o 4 The high-entropy oxide material is a spinel structure, and the SEM picture ( figure 2 ) shows that the prepared (CoCrCuFeNi) 3 o 4 The average particle size ...

Embodiment 2

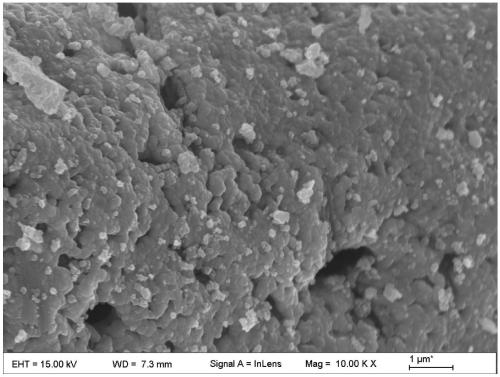

[0025] Weigh 29.01g of Co(NO 3 ) 2 ·6H 2 O, 40.02g of Cr(NO 3 ) 3 9H 2 O, 24.16g of Cu(NO 3 ) 2 ·3H 2 O, 40.4g of Fe(NO 3 ) 3 9H 2 O and 29.08g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 50mL of distilled water, and stirred evenly to obtain a mixed solution containing metal salts; then 180.16g of glucose, 1.8g of ammonium nitrate and 1.8g of ammonium acetate were weighed and added to the above mixed solution, and after stirring evenly, the pH of the mixed solution was adjusted with ammonia water to 7. Obtain a transparent sol; then heat the above transparent sol in a water bath at 90°C to remove the solvent water to obtain a loose, foamy gel; finally place the above gel in a muffle furnace at 500°C for 15 minutes, to get the final product. SEM image ( image 3 ) shows that the prepared (CoCrCuFeNi) 3 o 4 The average particle size of the high-entropy oxide material is 80nm, the morphology is spherical and has a porous structure.

Embodiment 3

[0027] Weigh 43.66g of Co(NO 3 ) 2 ·6H 2 O, 60.02g of Cr(NO 3 ) 3 9H 2 O, 36.24g of Cu(NO 3 ) 2 ·3H 2 O, 60.6g of Fe(NO 3 ) 3 9H 2 O and 43.62g of Ni(NO 3 ) 2 ·6H 2 O was dissolved in 80mL of distilled water and 20mL of ethanol solution, and stirred evenly to obtain a mixed solution containing metal salts; then 168.9g of tartaric acid and 3.38g of ammonium nitrate were added to the above mixed solution, stirred evenly, and the pH of the mixed solution was adjusted to 7 with ammonia water , to obtain a transparent sol; then heat the above transparent sol in an oil bath at 120°C to remove solvent water and obtain a loose, foamy gel; finally place the above gel in a microwave oven with an input power of 600W for 8 minutes , to get the final product. SEM image ( Figure 4 ) shows that the prepared (CoCrCuFeNi) 3 o 4 The average particle size of the high-entropy oxide material is 60nm, the morphology is spherical and has a porous structure.

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| The average particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com