Nano spinel type catalyst and preparation method thereof

A nano-spinel and catalyst technology, applied in chemical instruments and methods, physical/chemical process catalysts, combustion methods, etc., can solve the problems of poor control of precipitation end point, large catalyst particle size, affecting catalytic combustion activity, etc. Short test period, low cost, and the effect of reducing production costs

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0037] The embodiment of one aspect of the present invention provides a kind of preparation method of nano spinel type catalyst, comprises the following steps:

[0038] S1: Dissolving the A-position divalent metal nitrate in deionized water and stirring to obtain the A-position divalent metal nitrate solution;

[0039] S2: Dissolve the B-site trivalent metal nitrate in deionized water, and stir to obtain the B-site trivalent metal nitrate solution; slowly add the B-site trivalent metal nitrate solution to the A-site metal nitrate solution, and continue stirring Make it fully mixed to form a mixed solution of A-site and B-site metal nitrates;

[0040] In this step, the A-position divalent metal nitrate solution and the B-position trivalent metal nitrate solution are two kinds of solutions that do not react with each other. In order to make the two form a uniform mixed solution, when adding, it is necessary to add slowly, In order to avoid affecting each other during the additi...

Embodiment 1

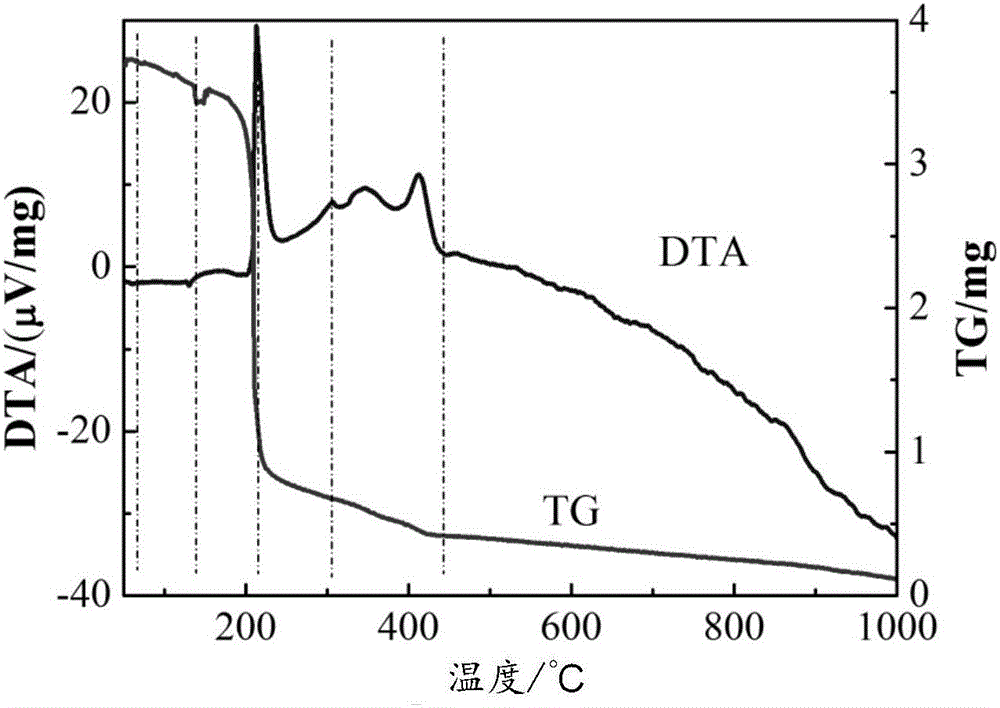

[0057] (1) 18.21g (0.075mol) Cu(NO 3 ) 2 ·3H 2 O was dissolved in 20ml deionized water, and stirred to obtain A solution; (2) 60.6g (0.15mol) Fe(NO 3 ) 3 9H 2 O was dissolved in 50ml of deionized water, and stirred to obtain solution B; solution B was slowly added to solution A, and kept stirring to make it fully mixed to form a mixed solution of A+B; (3) 47.28g (0.225mol) of citric acid monohydrate (C 6 h 8 o 7 ·H 2 O) be dissolved in 30ml deionized water, stir to obtain a citric acid solution; slowly add the citric acid solution to the A+B mixed solution, and keep stirring to make it fully mixed to form a sol precursor solution; (4) adjust the pH value to 7 with ammonia water , and stirred at 70°C for 5 hours, the solution was in a sol state; the sol was aged for 2 hours to form a gel, and the gel was air-dried at 130°C for 12 hours to form a xerogel; (5) Grind the xerogel into powder , placed in a porcelain element dish, ignited with a wooden stick on the surface o...

Embodiment 2

[0067] (1) 21.8g (0.075mol) Co(NO 3 ) 2 ·6H 2 O was dissolved in 20ml of deionized water, and stirred to obtain A solution; the remaining steps (2)-(6) were the same as in Example 1 to prepare a powdered nano-spinel catalyst.

[0068] The prepared nano spinel type catalyst catalytic combustion activity evaluation method of embodiment 2 is the same as embodiment 1;

[0069] The characterization and catalytic combustion activity evaluation results of the nano spinel type catalyst prepared by embodiment 2 are as follows:

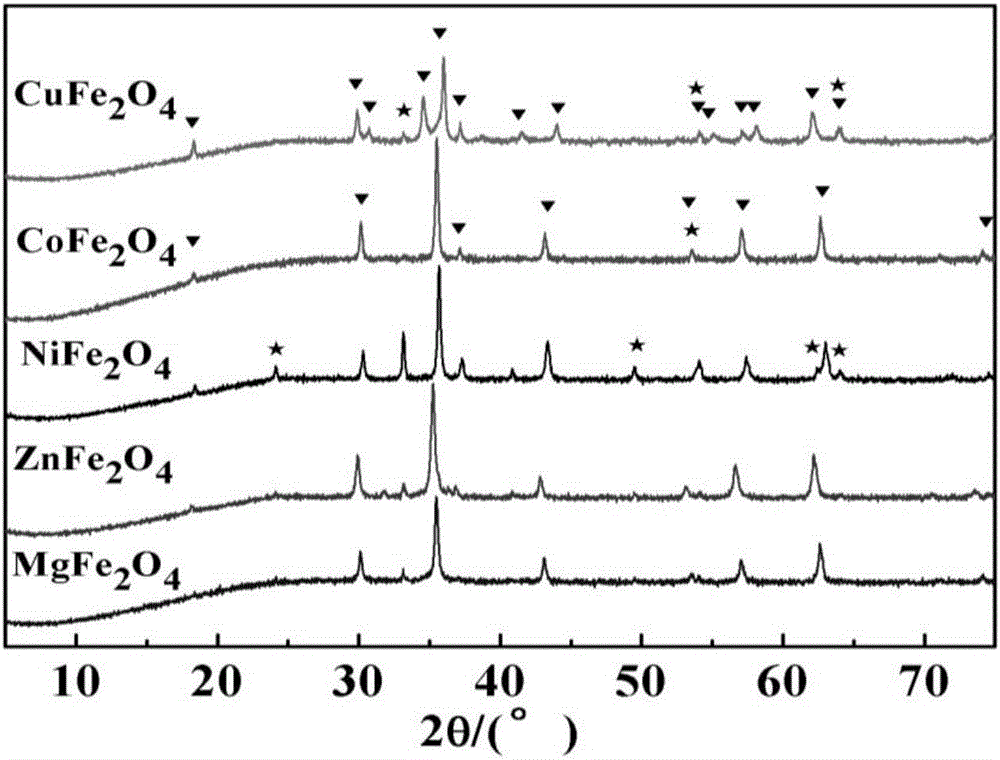

[0070] As can be seen from the X-ray diffraction (XRD) spectrogram, the prepared nano-spinel catalyst in Example 2 is in the CoFe 2 o 4 (JCPDS22-1086) diffraction peak, when 2θ=18.3°, 30.1°, 30.7°, 35.4°, 37.1°, 43.1°, 53.4°, 56.9°, 62.6°, 74.0°, it corresponds to CoFe 2 o 4 (111), (220), (311), (222), (400), (422), (511), (440), (533) crystal planes of spinel cubic Fd-3m crystal group , indicating that the main component of the catalyst prepared in this...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

| Average pore size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com