Surface modified positive pole material of lithium ion cell and preparation method thereof

A technology for lithium ion batteries and positive electrode materials, which is applied in the field of the preparation of positive electrode materials, can solve the problems of increased cost and process complexity, unfavorable large-scale production, unfeasible industrialization, etc., and achieves easy industrial production, low cost, and good cycle. performance effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] The preparation method of described lithium ion battery cathode material, comprises the following steps:

[0029] (1) uniformly mixing the additive and the positive active material to obtain a uniform mixture of the positive active material and the additive;

[0030] (2) compressing the mixture of the positive electrode active material and the additive obtained in (1) into a block under a pressure of 3 to 20 MPa;

[0031] (3) The mixture of positive electrode active material and additives compressed into blocks in (2) is first heated to temperature 1, temperature 1 is 50°C to 400°C, and the reaction time is 0.1 to 8.0 hours; then raised to temperature 2, The temperature 2 is 200° C. to 900° C., and the reaction time is 0.1 to 8.0 hours; thereby obtaining the positive electrode material of the lithium ion battery.

[0032]The added element in the additive may be 0.1-15% by weight of the positive electrode active material.

[0033] The principle of the surface coating m...

Embodiment 1

[0036] Preparation of a surface-coated modified lithium-ion battery positive electrode material: Li / Mn molar ratio 1:0.9~1.1 2 CO 3 and electrolytic MnO 2 After uniform mixing in a ball mill, heat treatment at 750°C for 20 hours to obtain lithium manganate LiMn with an average particle size of 10-15 μm 2 o 4 1. Mix aluminum nitrate and lithium manganate with the weight of aluminum accounting for 1.5% of lithium manganate, and then press them into blocks under a pressure of 10 MPa. Then, the positive electrode material of the present invention was obtained after treatment at 120° C. and 500° C. for 2 h, respectively.

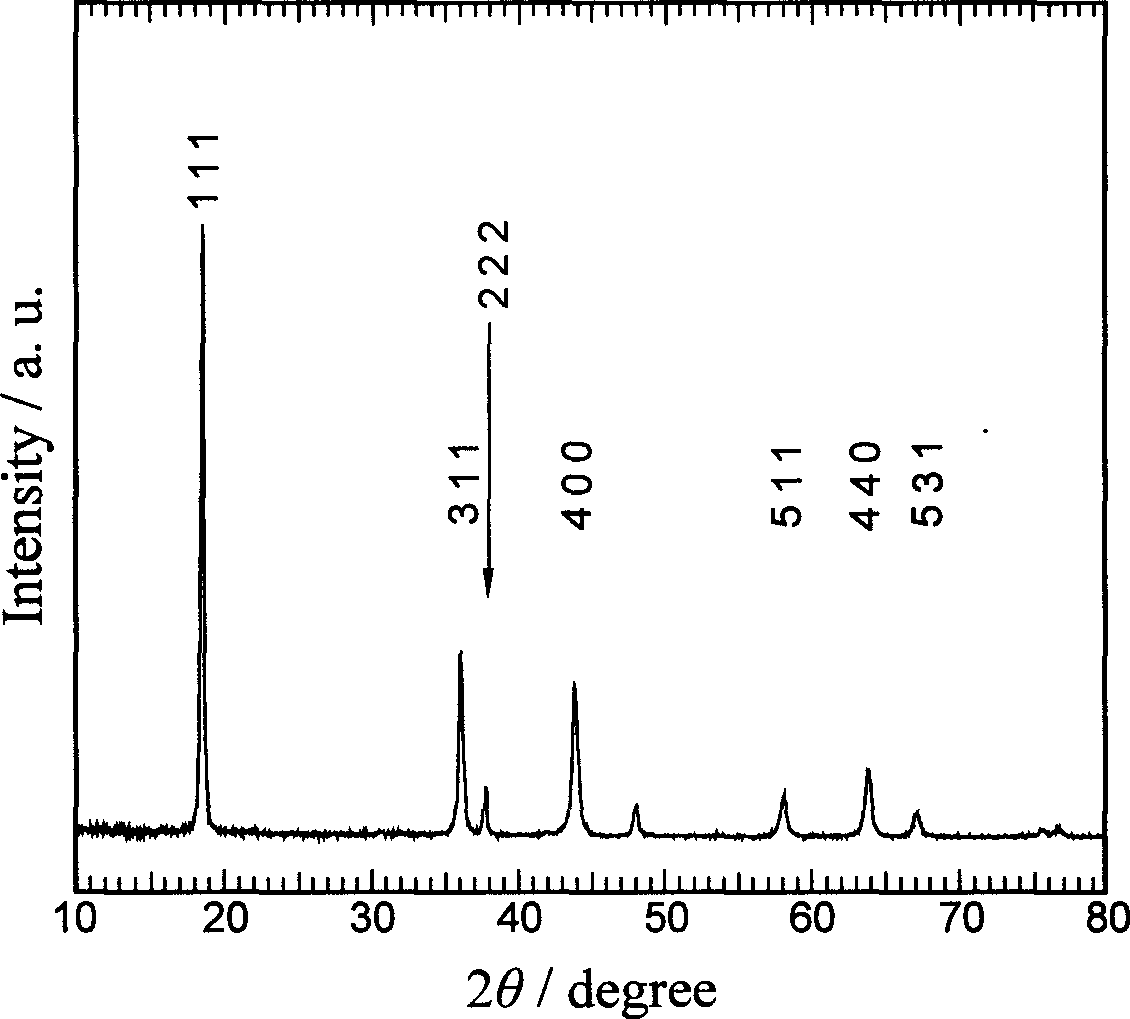

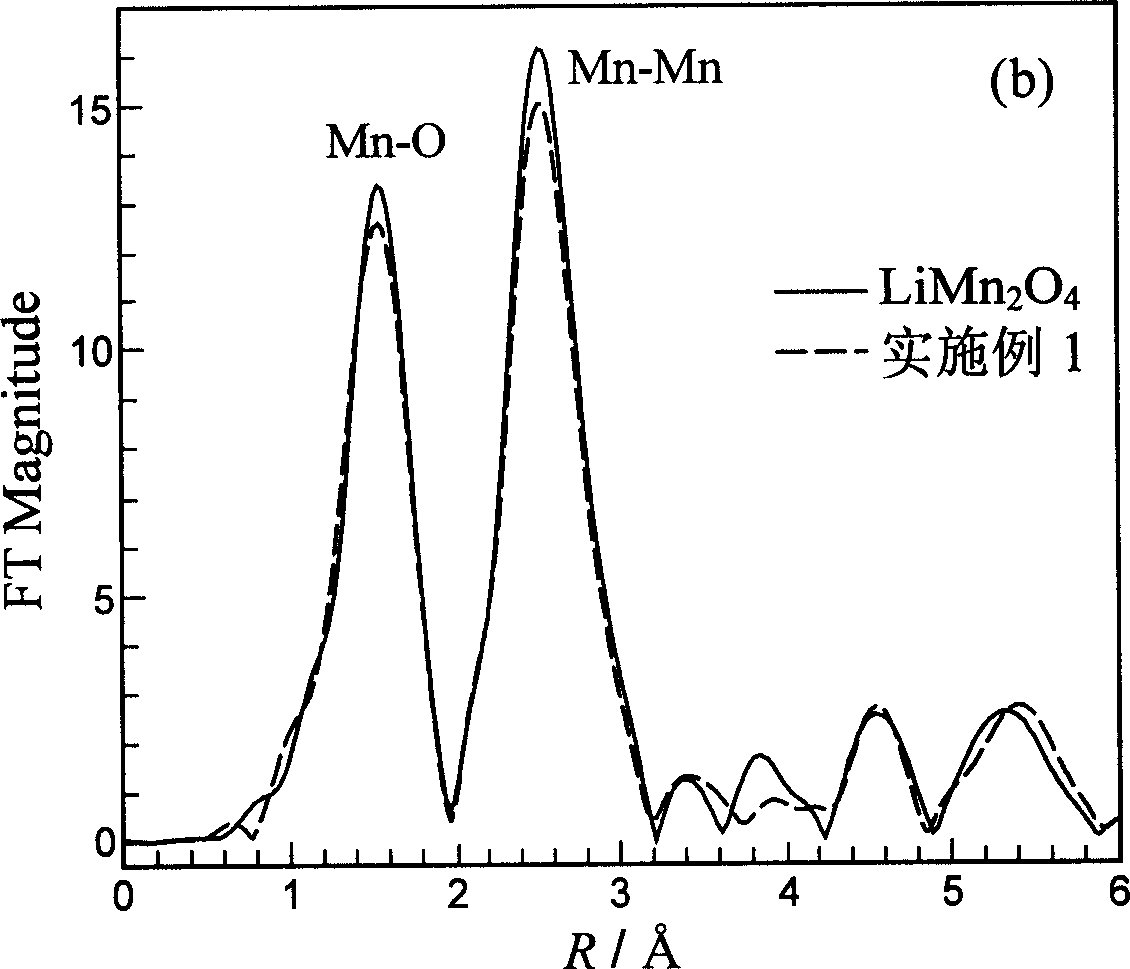

[0037] The obtained surface-coated modified LiMn was measured 2 o 4 Its XRD spectrum is shown in figure 1 , compared with the standard card, it is a spinel structure with intact crystal form, and no other diffraction peaks are observed.

[0038] The obtained surface-coated modified LiMn was measured 2 o 4 Its TEM photo. It can be seen from the figure th...

Embodiment 2

[0043] Preparation of a surface-coated modified lithium-ion battery cathode material: the same as in Example 1 except that the additive was changed from aluminum nitrate to zinc nitrate.

[0044] Example 2 has an initial discharge capacity of 120mA h / g at room temperature, and after 50 cycles at a rate of 0.5C, the capacity retention rate is 97.5%. The initial discharge capacity at 55°C was 115mA h / g, and there was no decay after 45 charge-discharge cycles, and the capacity increased to 116mA h / g.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com