Preparation method of doped black titanium dioxide

A technology of black titanium dioxide and titanium dioxide, applied in chemical instruments and methods, metal/metal oxide/metal hydroxide catalysts, chemical/physical processes, etc., can solve problems such as low yield of hydrothermal reaction and unsuitability for industrial production , to achieve good application prospects, low cost and simple preparation process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

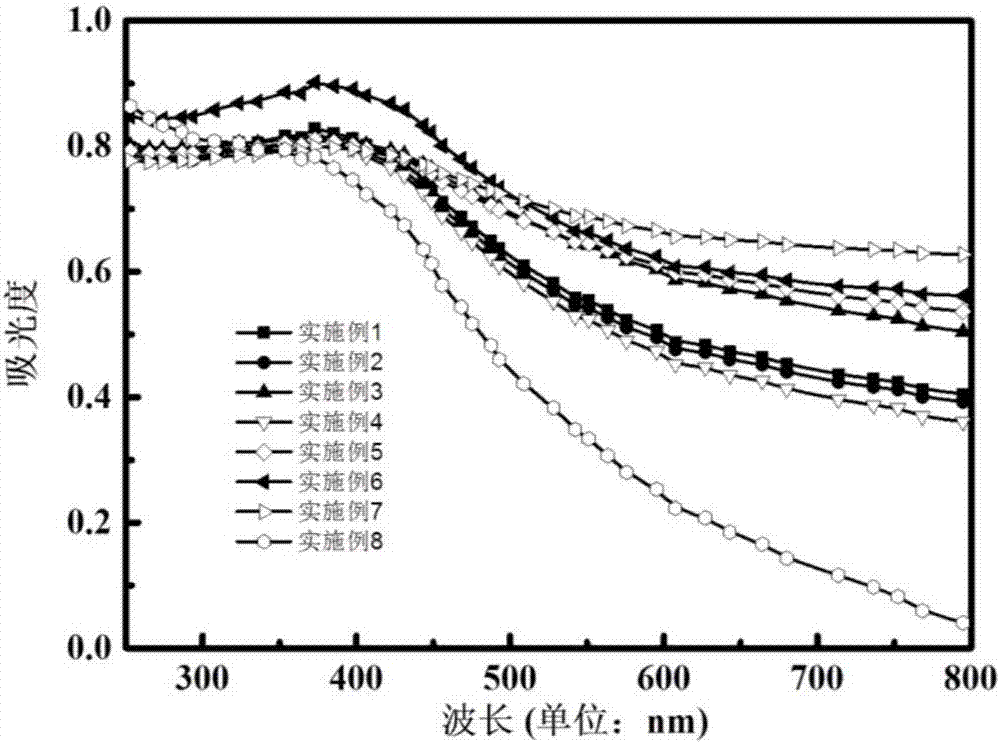

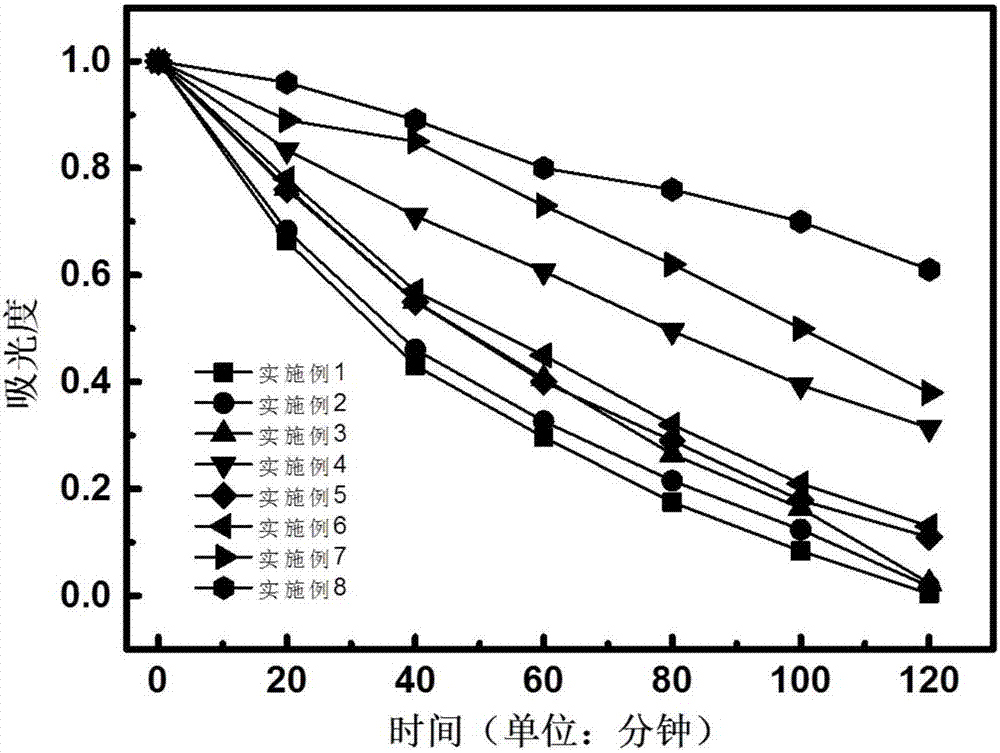

Embodiment 1

[0034] Measure 2.2L of tetrabutyl titanate and mix it with water to form a precipitate. The precipitate is fully washed with deionized water and centrifuged, then fully dried in an oven at 50°C to obtain amorphous titanium oxide;

[0035] Weigh 0.126kg of ferric nitrate nonahydrate and mix it with amorphous titanium oxide (Fe:Ti=0.01:1), mechanically mix it evenly, and place it in a nitrogen atmosphere furnace for annealing at 500°C for 12h;

[0036] After the sample was cooled with the furnace, it was washed with deionized water to remove unreacted nitrate, and after suction filtration, it was dried in an oven at 80°C to obtain Fe 3+ Doped black titanium oxide.

Embodiment 2

[0038] Measure 2.2L of tetrabutyl titanate and mix it with water to form a precipitate. The precipitate is fully washed with deionized water and centrifuged, then fully dried in an oven at 50°C to obtain amorphous titanium oxide;

[0039] Weigh 0.126kg of ferric nitrate nonahydrate and mix it with amorphous titanium oxide (Fe:Ti=0.005:1), mechanically mix it evenly and place it in a nitrogen atmosphere furnace for annealing at 500°C for 12h;

[0040] After the sample was cooled with the furnace, it was washed with deionized water to remove unreacted nitrate, and after suction filtration, it was dried in an oven at 80°C to obtain Fe 3+ Doped black titanium oxide.

Embodiment 3

[0042] Measure 2.2L of tetrabutyl titanate and mix it with water to form a precipitate. The precipitate is fully washed with deionized water and centrifuged, then fully dried in an oven at 50°C to obtain amorphous titanium oxide;

[0043] Weigh 2.52kg of ferric nitrate nonahydrate and mix it with amorphous titanium oxide (Fe:Ti=0.1:1), mechanically mix it evenly and place it in a nitrogen atmosphere furnace for annealing at 500°C for 12h;

[0044] After the sample was cooled with the furnace, it was washed with deionized water to remove unreacted nitrate, and after suction filtration, it was dried in an oven at 80°C to obtain Fe 3+ Doped black titanium oxide.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com