Quantum dots and preparation method thereof

A quantum dot and metal technology, applied in the field of nano-semiconductor material preparation, can solve the problems of poor stability of quantum dots, achieve excellent stability, improve stability, and reduce the effect of process flow

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

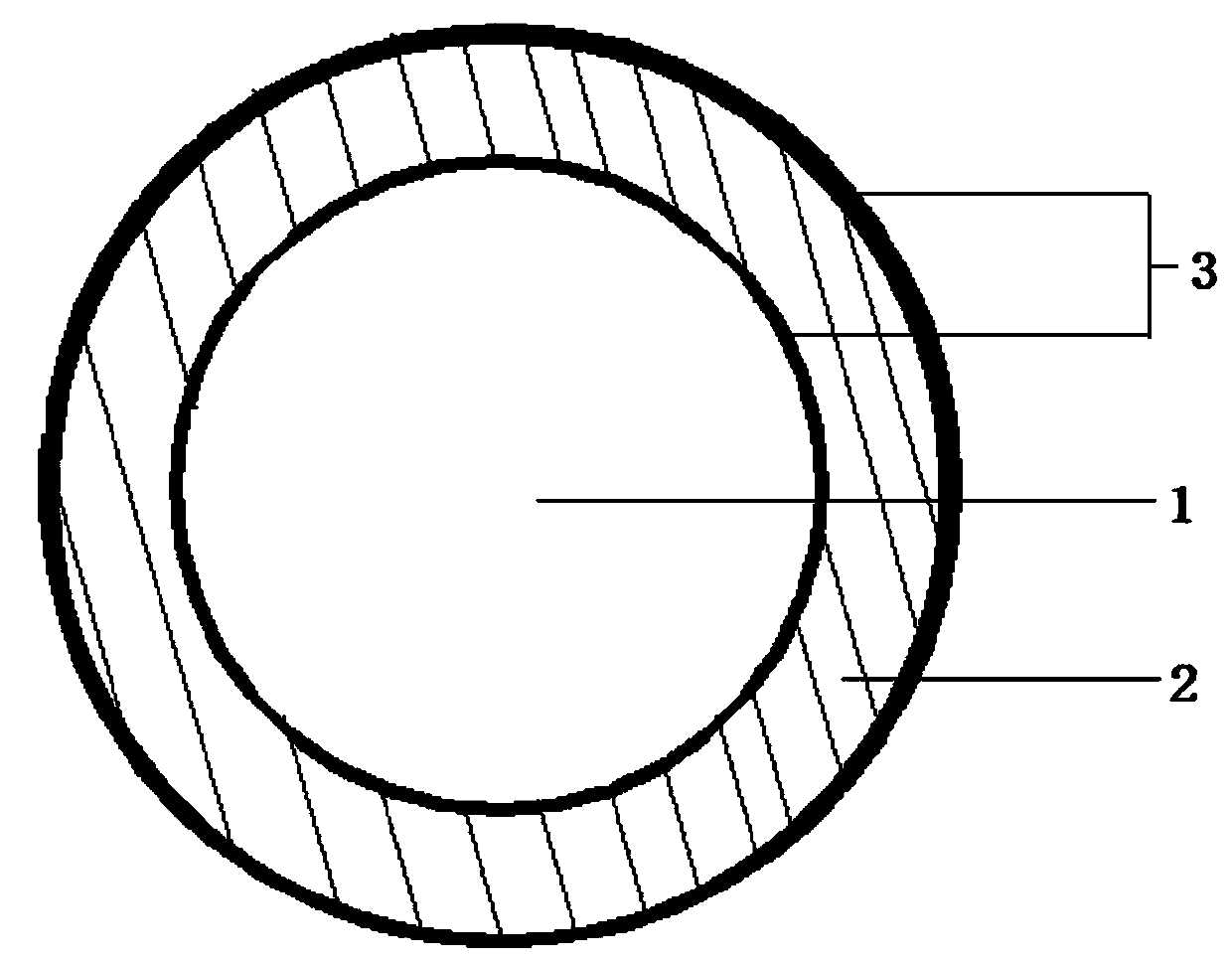

[0040] Embodiments of the present invention provide a quantum dot and a preparation method thereof. The structure of the quantum dot is as figure 1 Shown, the preparation method of this quantum dot comprises the following steps:

[0041] 1) Preparation of quantum dot core 1 solution:

[0042] (a) Weigh 5.0mmol selenium powder and 12mmol sulfur powder and place them in a conical flask, add 10mL tributylphosphine, and ultrasonically vibrate to obtain selenium-sulfur precursor solution A;

[0043] (b) Weigh 15 mmol of zinc oleate solid into 30 mL of octadecene, heat and dissolve in an inert environment to prepare precursor solution B;

[0044] (c) Weigh 1.0 mmol of cadmium oxide and 20 mmol of zinc oxide into a three-neck flask, add 40 mL of oleic acid and 60 mL of octadecene, and heat to 150°C under vacuum to obtain cadmium-zinc precursor solution C. Under the protection of nitrogen, the temperature was raised to 300°C, and solution A was injected into solution C with strong ...

Embodiment 2

[0054] Embodiments of the present invention provide a quantum dot and a preparation method thereof. The preparation method of this quantum dot comprises the steps:

[0055] 1) Preparation of quantum dot core 1 solution:

[0056] (a) Weigh 5.0mmol selenium powder and 12mmol sulfur powder and place them in a conical flask, add 10mL tributylphosphine, and ultrasonically vibrate to obtain selenium-sulfur precursor solution A;

[0057] (b) Weigh 15 mmol of zinc oleate solid into 30 mL of octadecene, heat and dissolve in an inert environment to prepare precursor solution B;

[0058] (c) Weigh 1.0 mmol of cadmium oxide and 20 mmol of zinc oxide into a three-neck flask, add 40 mL of oleic acid and 60 mL of octadecene, and heat to 150°C under vacuum to obtain cadmium-zinc precursor solution C. Under the protection of nitrogen, the temperature was raised to 300°C, and solution A was injected into solution C with strong stirring. After reacting for 10 minutes, the temperature was lower...

Embodiment 3

[0068] Embodiments of the present invention provide a quantum dot and a preparation method thereof. The preparation method of this quantum dot comprises the steps:

[0069] 1) Preparation of quantum dot core 1 solution:

[0070] (a) Weigh 5.0mmol selenium powder and 12mmol sulfur powder and place them in a conical flask, add 10mL tributylphosphine, and ultrasonically vibrate to obtain selenium-sulfur precursor solution A;

[0071] (b) Weigh 15 mmol of zinc oleate solid into 30 mL of octadecene, heat and dissolve in an inert environment to prepare precursor solution B;

[0072] (c) Weigh 1.0 mmol of cadmium oxide and 20 mmol of zinc oxide into a three-neck flask, add 40 mL of oleic acid and 60 mL of octadecene, and heat to 150°C under vacuum to obtain cadmium-zinc precursor solution C. Under the protection of nitrogen, the temperature was raised to 300°C, and solution A was injected into solution C with strong stirring. After reacting for 10 minutes, the temperature was lower...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com