Highly-heatproof polyamide composition and preparation method thereof

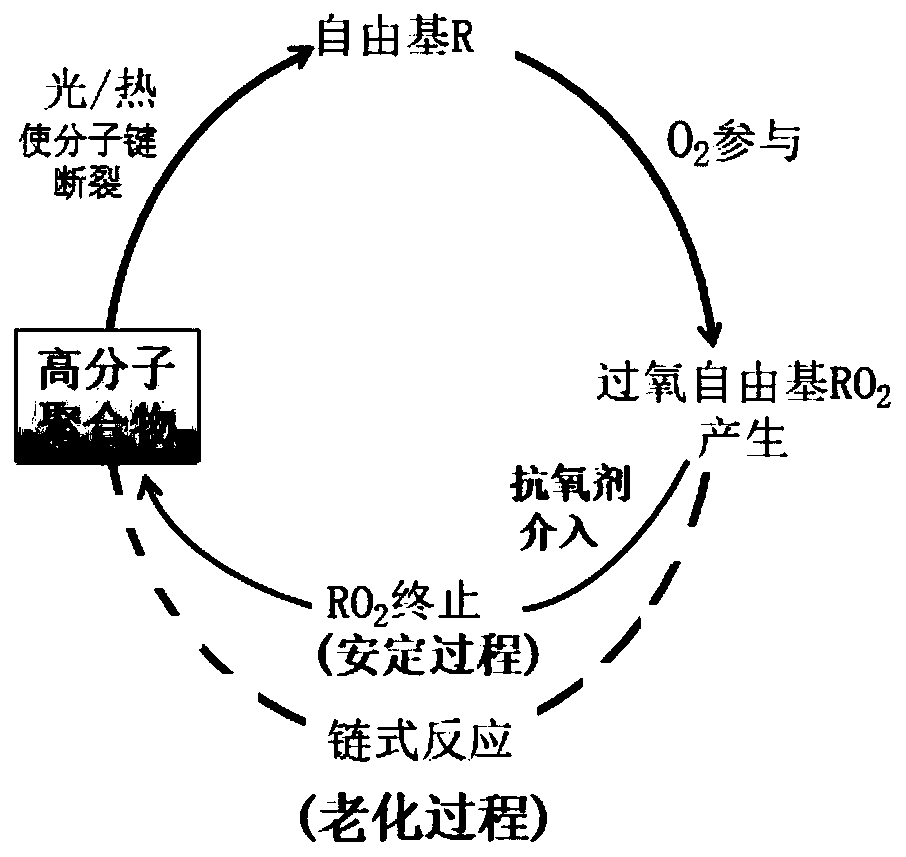

A polyamide composition, high heat-resistant technology, applied in the field of high heat-resistant polyamide composition and its preparation, can solve the problems of insufficient high-temperature thermal aging performance and mechanical properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

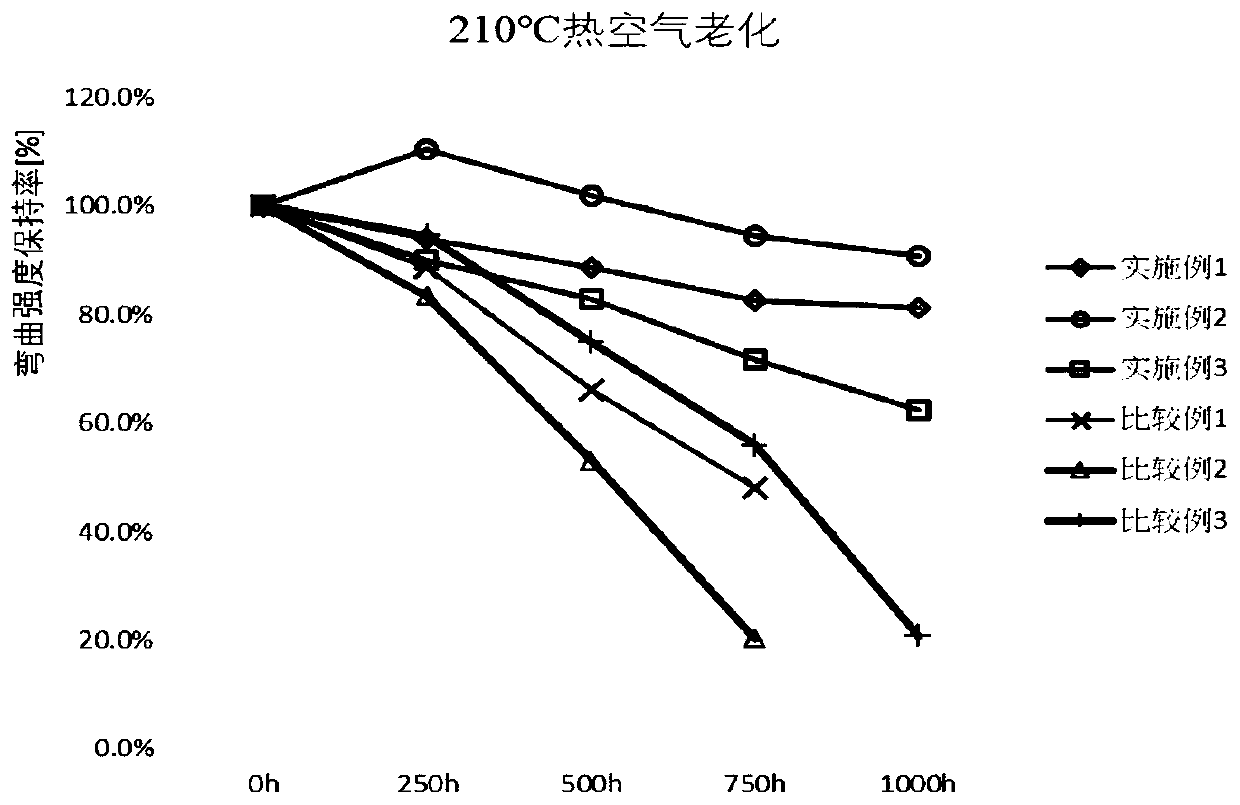

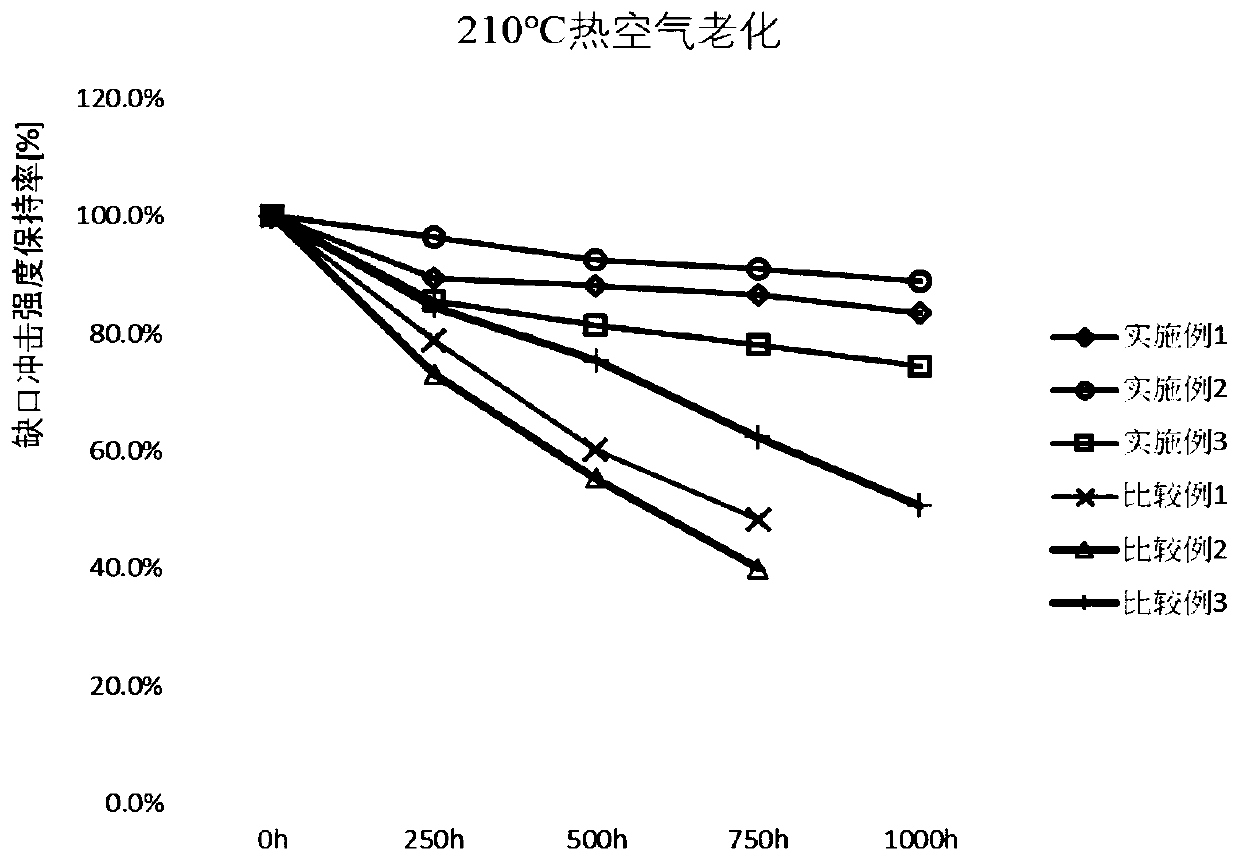

Examples

Embodiment Construction

[0060] The present invention is further illustrated by the following examples. It should be understood that the following examples are for illustrative purposes only, and are not intended to limit the present invention.

[0061] The following materials were used in Examples and Comparative Examples:

[0062] PA66-1 refers to a PA66 resin having about 50 mmol / kg of amino terminal groups and about 80 mmol / kg of carboxyl terminal groups, a relative viscosity of 2.7, a melting point of 260° C., and a glass transition temperature of 60° C., commercially available.

[0063] PA66-2 refers to a PA66 resin having about 85 mmol / kg of amino terminal groups and about 45 mmol / kg of carboxyl terminal groups, a relative viscosity of 2.7, a melting point of 260° C., and a glass transition temperature of 60° C., commercially available.

[0064] PA6 refers to PA6 resin, with a relative viscosity of 2.7, a melting point of 220°C, and a glass transition temperature of 55°C, a commercially availa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Melting point | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

| Melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com