Steel-concrete mixing type anti-shearing connecting piece

A technology of shear connectors and reinforced concrete, which is applied in the direction of construction and building construction, and can solve the problems of large amount of double-hole steel plate steel, unfavorable joint concrete stress, and complex construction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In conjunction with the accompanying drawings, the following embodiments of the present invention are given, but the present invention is not limited to the following embodiments, and it covers the modifications and equivalents described in the patent and within the scope of the claims.

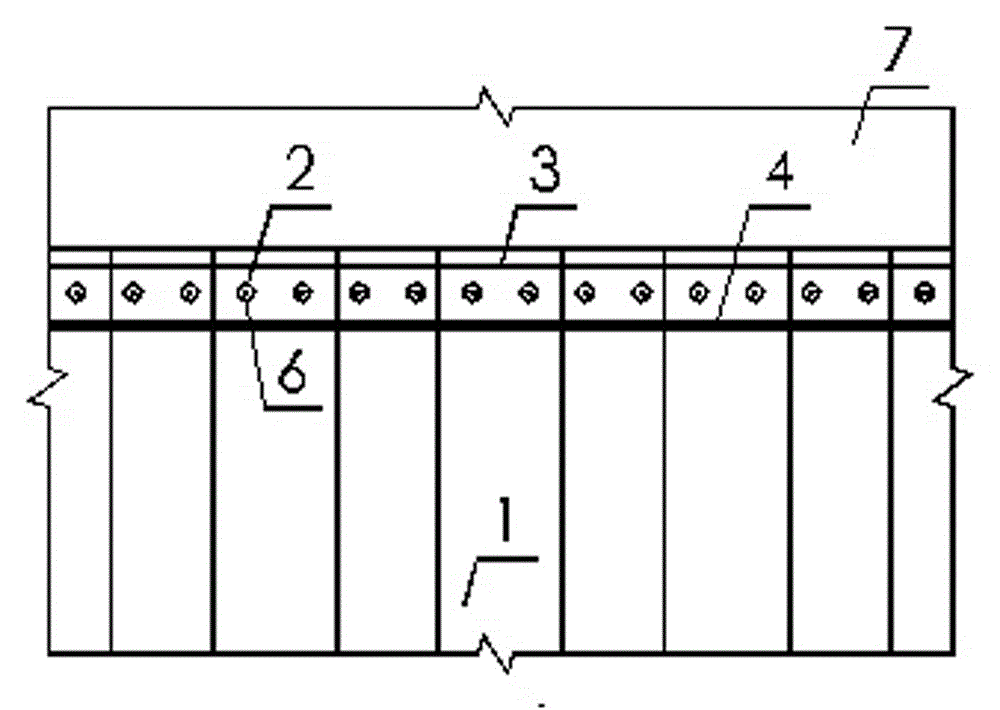

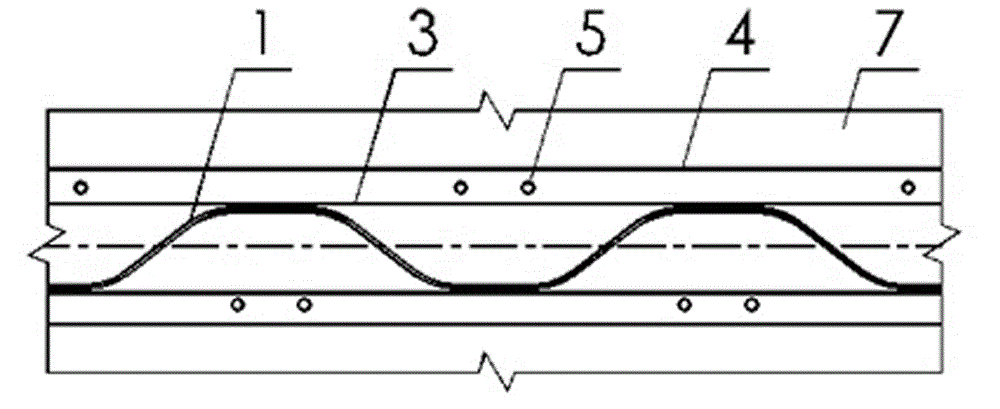

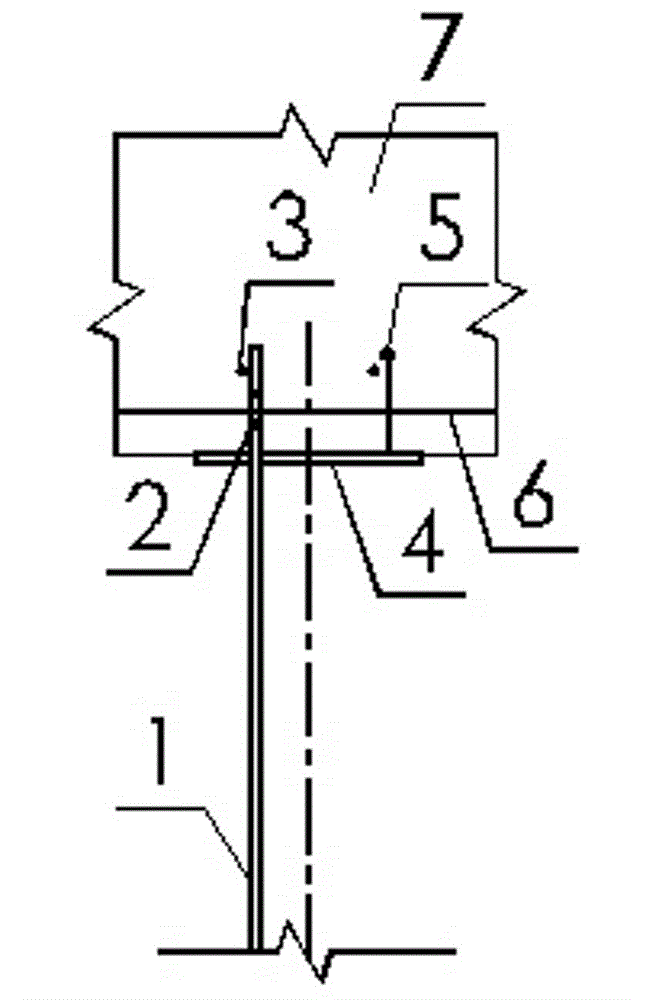

[0022] Figure 1~3 Shown is a steel-concrete hybrid shear connection suitable for the connection between a corrugated steel web and a concrete roof. Open a hole 2 on the top of the corrugated steel web 1, and weld one or more combined steel bars 3 (also known as reinforcing bars) longitudinally along the two sides of the corrugated steel web 1 on the upper part of the opening 2 to restrain the corrugated steel web The longitudinal deformation of the combined steel bar 3 is located at the joint surface of the corrugated steel web 1 and the concrete roof 7 . When each side is provided with two or more combined reinforcing bars 3, the two or more combined reinforcing bars are arranged up...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com