Flame-retardant polyurethane material and preparation method thereof

A polyurethane material and flame retardant technology, which is applied in the field of flame retardant polyurethane material and its preparation, can solve the problems of large addition amount, impact on mechanical properties of compound flame retardant materials, and poor compatibility, so as to improve dispersion and reduce The total amount of heat released and the effect of improving flame retardancy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0030] A method for preparing a flame-retardant polyurethane material, comprising the following steps: adding expandable graphite, ammonium polyphosphate and phytic acid-modified graphene oxide into polyether polyol, stirring evenly, then adding isocyanate, stirring evenly, After foaming, it is cured at room temperature.

[0031] Polyether polyol, isocyanate, expandable graphite (EG), ammonium polyphosphate (APP), phytic acid modified graphene oxide (fGO-p) and graphene oxide (GO) are shown in Table 1.

[0032] Formulation and limiting oxygen index of table 1 polyurethane material

[0033]

[0034] The weight ratio of EG and APP can be 1:1, 2:1, 3:1 or 4:1, but when EG / APP=3:1, the limiting oxygen index is the highest. From Example 4, Comparative Examples 2 and 3, it can be seen that the modified GO has better flame retardancy and its LOI value is 26.5%, which is higher than 25.9% of the unmodified GO.

[0035] Embodiment four, comparative examples one to three are tested...

Embodiment 7

[0045] Modified graphene oxide is octadecylamine-modified graphene oxide (fGO-o), and octadecylamine-modified graphene oxide is prepared by the following method: 2g octadecylamine is ultrasonically dissolved in 100ml In the aqueous solution of 95% (volume fraction) ethanol, obtain solution A; Ultrasonic disperse 2g graphite oxide powder in the deionized water of 100ml, obtain solution B; Then solution A is poured in the there-necked flask, joins in the solution B, Open the condensed water under magnetic stirring, reflux reaction in an oil bath at 100° C. for 20 h, centrifuge, wash and dry, and obtain octadecylamine-modified graphene oxide.

[0046] A kind of flame-retardant polyurethane material, the formula of raw material parts by weight is shown in Table 2.

[0047] Table 2 Polyurethane composite material formula and its corresponding limiting oxygen index

[0048]

[0049] It can be seen from Table 2 that compared with the addition of GO, the addition of FGO can increa...

Embodiment 8

[0053] Modified graphene oxide is IPDI-modified graphene oxide (fGO-i), and the IPDI-modified graphene oxide is prepared by the following method: 2g graphene oxide is ultrasonically dispersed in 100ml of DMF solution, and then dripped with a glue head Add 5 drops of dibutyltin dilaurate (DBTDL) dropwise to the tube, and finally add 2ml of IPDI, stir and react for 22 hours at a constant temperature of 90°C, then filter, wash and dry.

[0054] A method for preparing a flame-retardant polyurethane material, the formula of which is shown in Table 3 in parts by weight of raw materials.

[0055]

[0056]

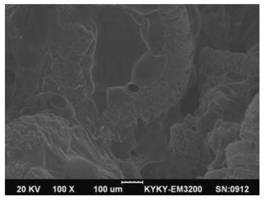

[0057] After modification, because the surface of FGO has unreacted isocyanate groups, it can participate in the foaming reaction of polyurethane, and can be better compatible with the polyurethane matrix, which improves the defect that GO is easy to agglomerate and increases the number of defects in the polyurethane foam structure.

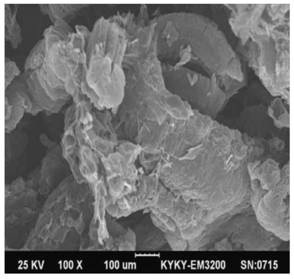

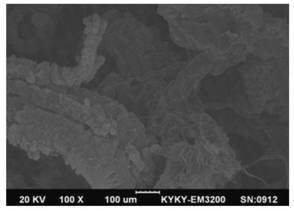

[0058] like Figure 7 and 8 As shown, ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com