Reagent for wet coating of high-nickel ternary positive electrode material as well as preparation method and application of reagent

A technology of wet coating and positive electrode materials, which is applied in the direction of chemical instruments and methods, electrical components, battery electrodes, etc., can solve the problems of cycle diving, material performance degradation, affecting material cycle life and safety performance, etc., and achieve the goal of blocking corrosion Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

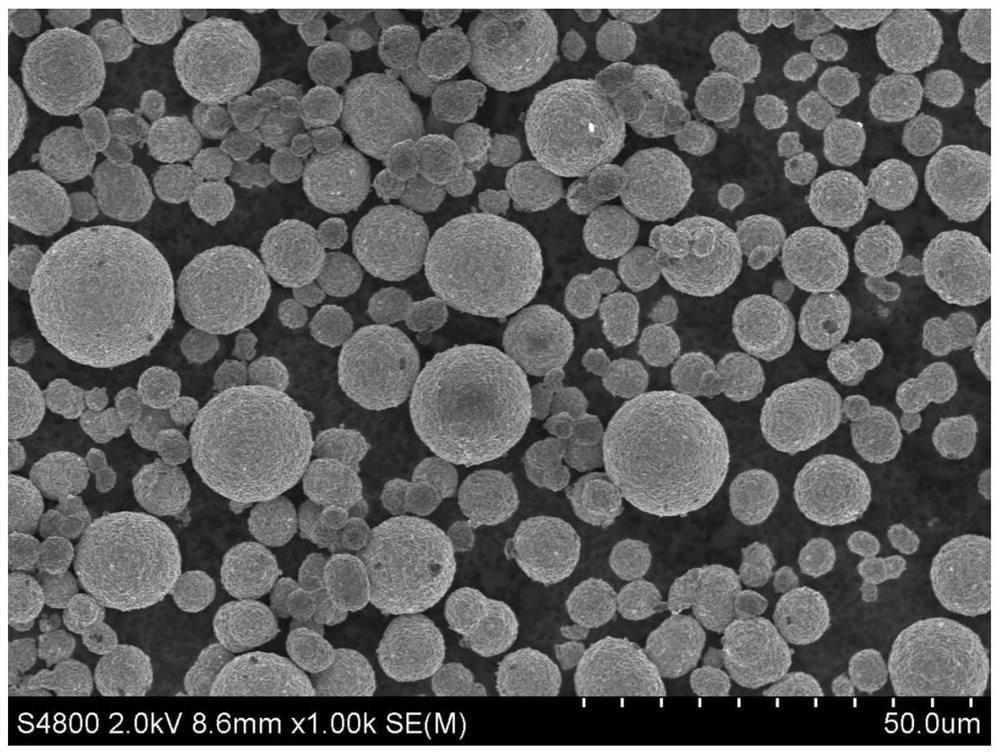

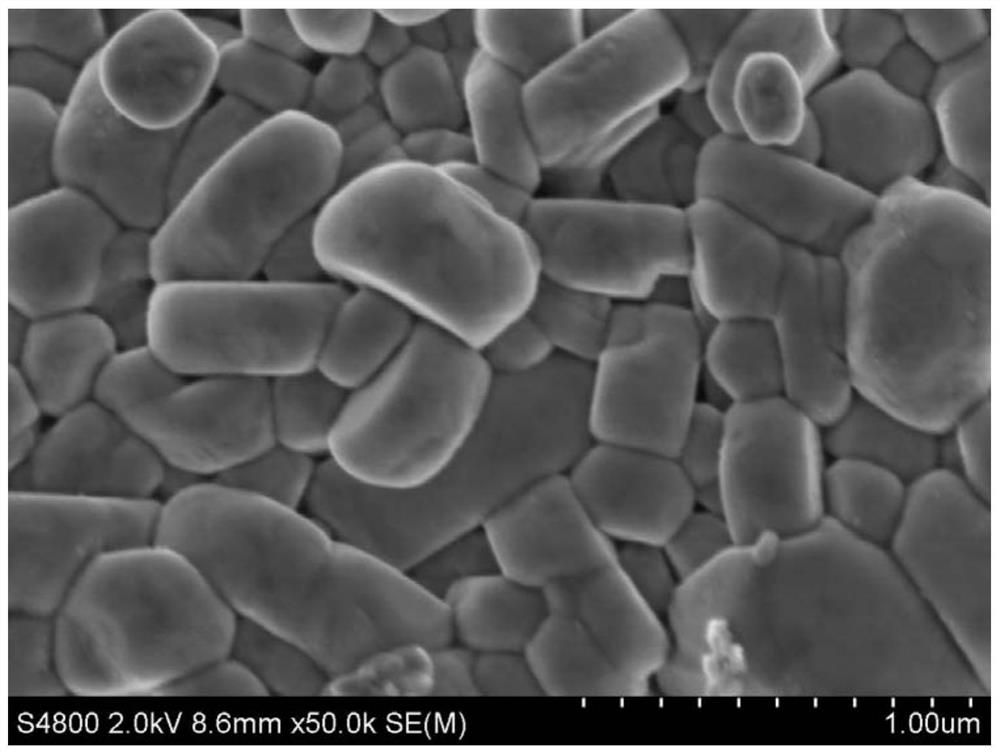

Image

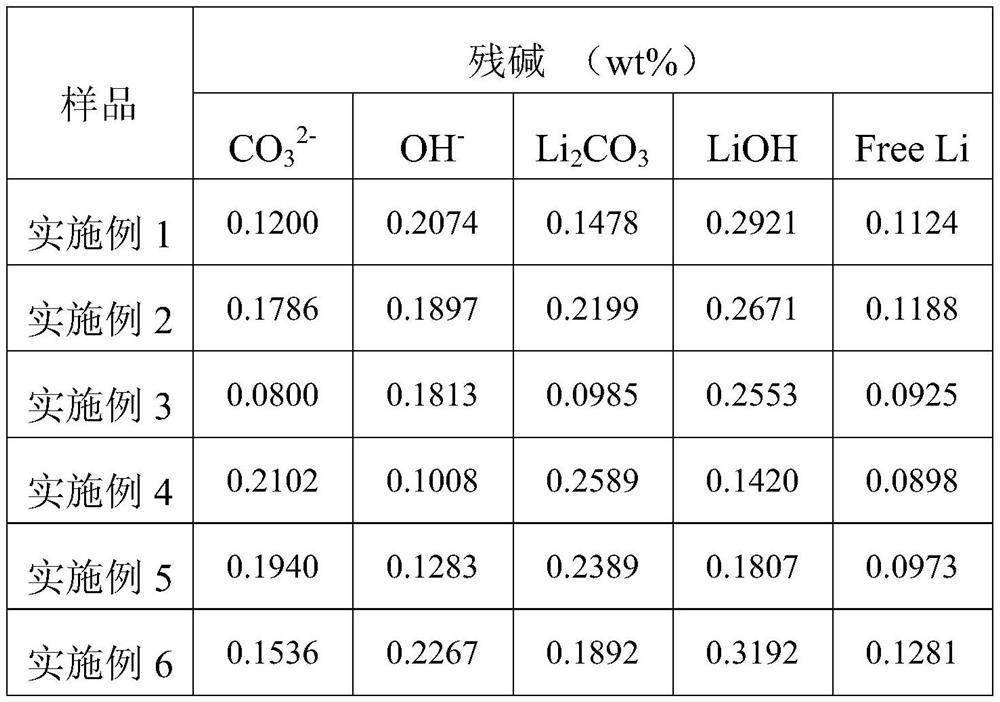

Examples

Embodiment 1

[0035] Al is preferred 2 (SO 4 ) 3 , MgSO 4 , Mn(CH 3 COO) 2 , MnSO 4 and Li 2 CO 3According to the molar ratio of metal ions aluminum ion, magnesium ion, manganese ion, manganese ion and lithium ion 1:1:0.5:0.5:1, weigh the mass respectively, dissolve them in 1L deionized water, stir in the reaction kettle at 30°C for 2h, and let stand A mixed salt solution with a total metal molar mass of 0.25 mol / L was obtained, which was recorded as reagent 1 for wet coating.

[0036] application:

[0037] S1. Put Ni 0.83 co 0.12 mn 0.05 (OH) 2 The ternary precursor is packed in a bowl, and pre-oxidized in an oxygen atmosphere furnace at 400°C for 2 hours to obtain a composite metal oxide; the average particle size of the nickel-cobalt-containing ternary precursor is 10.0um, and the specific surface area is 5m 2 / g, bulk density is 1.72g / cm 3 , the tap density is 2.05g / cm 3 ;

[0038] S2. Mix the composite metal oxide with battery-grade lithium hydroxide monohydrate at a li...

Embodiment 2

[0042] Al(NO 3 ) 3 , Ti(SO 4 ) 2 , NH 4 h 2 PO 4 and LiNO 3 Weigh the masses of aluminum ions, titanium ions, phosphorus ions and lithium ions respectively, dissolve them in 1L of deionized water and stir in a reactor at 20°C for 5 hours, and after standing still, the molar mass (the sum of the molar weights of metal ions and phosphorus ions) is 0.20 mol / L mixed salt solution, recorded as reagent 2 for wet coating.

[0043] application:

[0044] S1. Put Ni 0.80 co 0.10 mn 0.10 (OH) 2 The ternary precursor is packed in a bowl, and pre-oxidized in an air atmosphere furnace at 450°C for 6 hours to obtain a composite metal oxide; the average particle size of the nickel-cobalt-containing ternary precursor is 10.5um, and the specific surface area is 8m 2 / g, bulk density 1.75g / cm 3 , the tap density is 2.10g / cm 3 ;

[0045] S2. Mix the composite metal oxide with battery-grade lithium hydroxide monohydrate at a lithium-to-metal molar ratio of 1.06:1, and add ZrO with a...

Embodiment 3

[0049] Al[OCH(CH 3 ) 2 ] 3 and CTAB were weighed according to the molar ratio of aluminum and bromide ions of 2:1, dissolved in 1L of 75% ethanol solution respectively, stirred at 60°C for 3 hours, and weighed according to the molar ratio of aluminum and silicon ions of 1:1. 8 h 20 o 4 The Si solution was slowly dropped into the mixed solution and continued to stir for 7 hours. After standing still, a mixed salt solution with a total metal molar mass of 0.5 mol / L was obtained, which was recorded as reagent 3 for wet coating.

[0050] application:

[0051] S1. Put Ni 0.88 co 0.09 al 0.03 (OH) 2 The ternary precursor is packed in a bowl, and pre-oxidized in an air atmosphere furnace at 650°C for 4 hours to obtain a composite metal oxide; the average particle size of the nickel-cobalt-containing ternary precursor is 11.0um, and the specific surface area is 9m 2 / g, bulk density is 1.8g / cm 3 , the tap density is 2.25g / cm 3 ;

[0052] S2. Mix the composite metal oxide w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average particle size | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Bulk density | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com