Post-cutting passivation method of silicon-based semiconductor device and silicon-based semiconductor device

A semiconductor and post-passivation technology, which is applied in the field of silicon-based semiconductor devices and post-cutting passivation of silicon-based semiconductor devices, can solve the problems of battery sheet efficiency drop and conversion efficiency drop

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

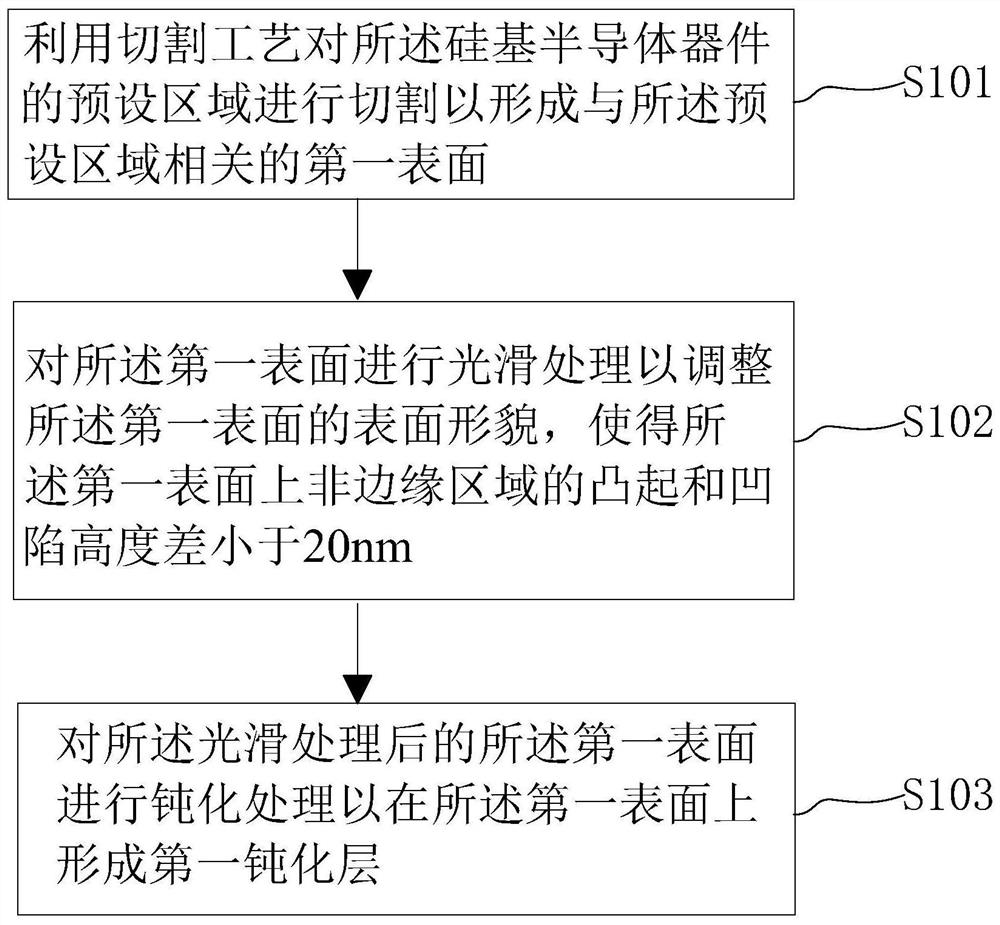

[0134] The first passivation layer is a silicon oxide layer, which can be made by oxidation reaction. Since hot oxygen requires high temperature, it can be combined with surface smoothing treatment steps, the specific steps are as follows.

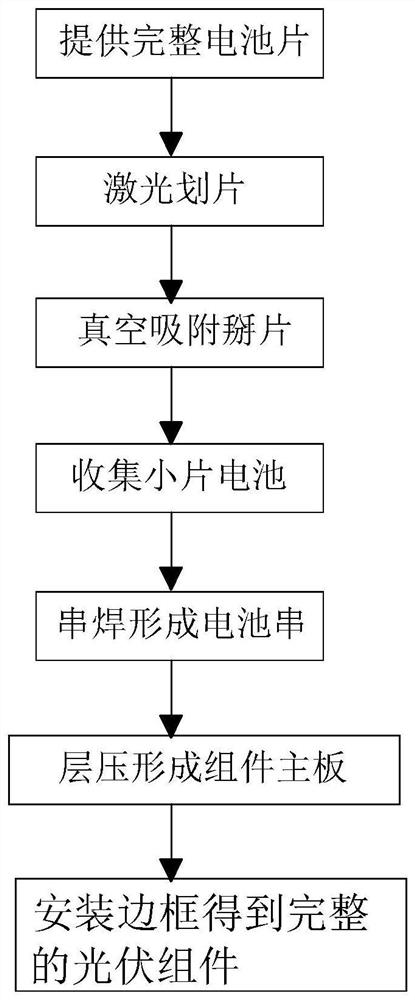

[0135] (1) The complete silicon-based semiconductor device is divided to obtain small silicon-based semiconductor devices.

[0136] (2) Place a small silicon-based semiconductor device in a low-pressure vacuum environment, and use a high-energy particle beam, such as He ions, to bombard the cross-section through an accelerator and focus. At this time, the temperature of the cavity where the silicon-based semiconductor device is located should not exceed 350°C.

[0137] (3) After the high-energy particle beam bombardment, nitrogen, water vapor and oxygen can be sprayed on the section. At this time, the temperature of the silicon-based semiconductor device is 150°C-250°C, and the gaseous water vapor and oxygen react with the silicon surfac...

Embodiment 2

[0141] The first passivation layer is a silicon oxide layer, which can be obtained by an ozone oxidation method, and the specific steps are as follows.

[0142] (1) The complete silicon-based semiconductor device is divided to obtain small silicon-based semiconductor devices.

[0143] (2) Place a small silicon-based semiconductor device in a low-pressure vacuum environment, and use a high-energy particle beam, such as He ions, to bombard the cross-section through an accelerator and focus. At this time, the temperature of the cavity where the silicon-based semiconductor device is located should not exceed 350°C.

[0144] (3) After the high-energy particle beam bombardment, ozone can be sprayed on the cross section. At this time, the silicon-based semiconductor device is still in the low-pressure vacuum chamber, and is not taken out to be in contact with the air, so as to avoid the oxygen in the air from causing a natural oxide layer of extremely poor quality on the silicon-bas...

Embodiment 3

[0148] The first passivation layer is a silicon nitride layer, which can be obtained by chemical deposition, and the specific steps are as follows.

[0149] (1) The complete silicon-based semiconductor device is divided to obtain small silicon-based semiconductor devices.

[0150] (2) Place a small piece of silicon-based semiconductor device in a low-pressure vacuum environment, and use a high-energy particle beam, such as He ions or Ne ions, to bombard the cross-section through an accelerator and focus. At this time, the temperature of the cavity where the silicon-based semiconductor device is located should not exceed 350°C.

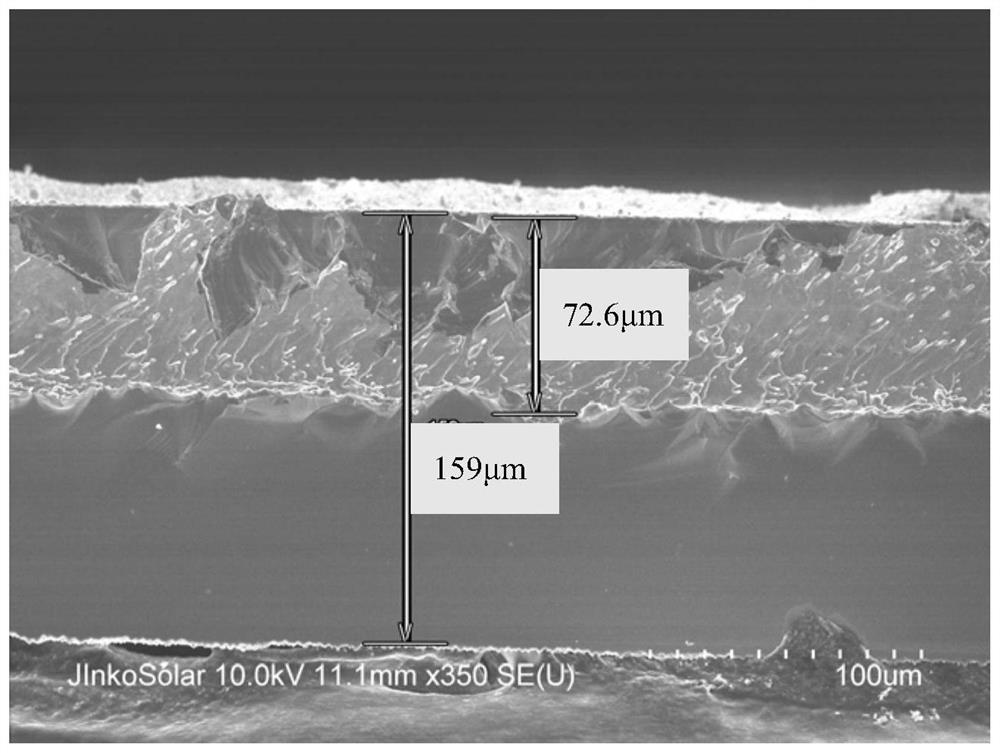

[0151] (3) After the bombardment of the high-energy particle beam is completed, the method of chemical vapor deposition is used to pass the plasma mixed with ammonia gas and silane to the cross-sectional surface to complete the silicon nitride film deposition process. The thickness of the film layer can be set by the reaction time. Preferably, the thi...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com