A flexible substrate and a preparation method thereof

A flexible substrate and film technology, applied in the direction of climate sustainability, final product manufacturing, sustainable manufacturing/processing, etc., can solve the problem of transistor device characteristic failure, flexible display device display quality degradation, and OLED device luminous efficiency. life and other issues, to achieve the effect of extending the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0044] The preparation method of the flexible substrate of the present invention comprises the following steps:

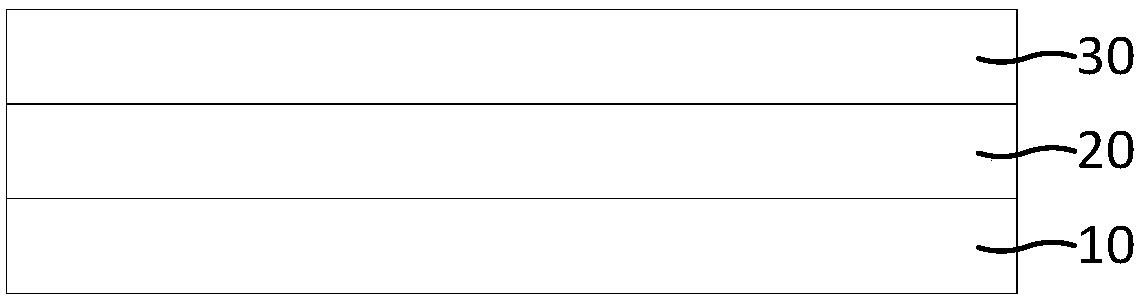

[0045] (1) Prepare an organic polymer precursor, add nanoparticles to the organic polymer precursor, the nanoparticles are selected from at least one substance in titanium oxide, zinc oxide or silicon oxide, and coat it on a hard substrate The organic polymer precursor doped with nanoparticles is heated and cured to obtain the first film layer 10 .

[0046] The hard substrate is used as a carrier to support the subsequent flexible substrate, thin film transistor and OLED module. After the flexible display device is prepared, it is separated from the flexible display device after laser lift-off. As an example, a glass substrate may be used as the hard substrate.

[0047] The organic polymer precursor, that is, the state in which the organic polymer exists before forming the organic polymer film, may be a solution composed of raw materials for the organic polymer, o...

Embodiment

[0056] (1) Prepare the first film layer 10 on the hard substrate.

[0057] Dissolve 4,4'-diaminodiphenyl ether in N,N-dimethylacetamide, and mechanically stir until 4,4'-diaminodiphenyl ether is completely dissolved to obtain a mixed solution; then add to the above mixed solution Add an equimolar amount of 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride, stir mechanically until the 3,3',4,4'-diphenyl ether tetracarboxylic dianhydride is completely dissolved, and continue stirring for 2h~ After 4h, a polyamic acid (PAA) solution was obtained. Then adding nano-SiO to the polyamic acid (PAA) solution 2 , after stirring or ultrasonic dispersion, the nano-SiO 2 Uniformly dispersed in polyamic acid (PAA) solution to obtain the precursor of polyimide (PI) doped with nanoparticles.

[0058] Use a low-speed rotary film coater to coat one surface of a glass substrate, place it in a thermal oven or an IR furnace for heating and curing, and the heating temperature is 150 ° C to 30...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com