Viscoelastic body anti-mildew and anticorrosion adhesive for buried pipelines, adhesive tape and preparation method thereof

A buried pipeline, viscoelastic technology, applied in viscoelastic anti-mildew anti-corrosion tape and its preparation, viscoelastic anti-mildew anti-corrosion adhesive field, can solve the inconvenience of repairing wounds, strict construction requirements, poor UV resistance and other problems, to achieve the effect of excellent anti-mold and anti-corrosion performance, improve peel strength, and prevent mold erosion.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0050] The viscoelastic anti-mildew and anti-corrosion glue used for buried pipelines in this embodiment consists of the following components in parts by mass:

[0051]

[0052]

[0053] The preparation method of the viscoelastic anti-mildew and anti-corrosion adhesive used for buried pipelines in this embodiment comprises the following steps:

[0054] (1) Accurately take each component according to the mass parts, add the polymer viscoelastic material, reinforcing glue, antioxidant, plasticizer into the kneader, and knead for 1 hour under the condition of vacuumizing and 150°C;

[0055] (2) Add fillers and pigments, and continue kneading for 1 hour under vacuum at 130°C;

[0056] (3) Cool down to 100°C, add antifungal agent, and continue kneading for 20 minutes under vacuum conditions to obtain the product.

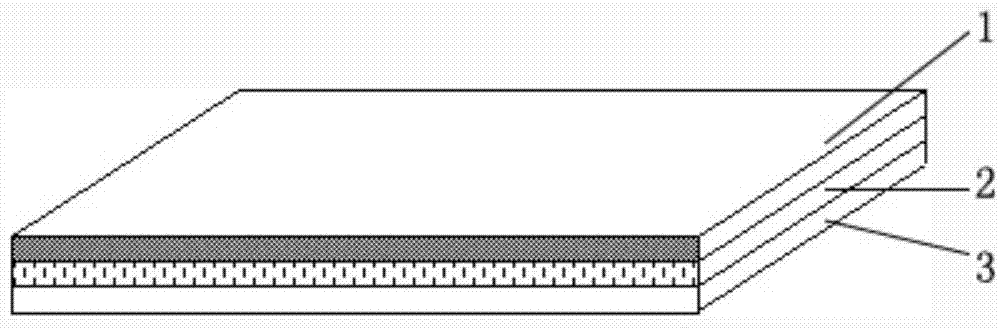

[0057] In this embodiment, the viscoelastic anti-mildew and anti-corrosion adhesive tape used for buried pipelines (structural schematic diagram is as follows fi...

Embodiment 2

[0060] The viscoelastic anti-mildew and anti-corrosion glue used for buried pipelines in this embodiment consists of the following components in parts by mass:

[0061]

[0062] The preparation method of the viscoelastic anti-mildew and anti-corrosion adhesive used for buried pipelines in this embodiment is the same as that in Embodiment 1.

[0063] The viscoelastic anti-mildew and anti-corrosion adhesive tape (the same structure as in Example 1) used for buried pipelines in this embodiment includes a base film layer, on which a glue layer is provided, and the base film layer adopts high-density polyethylene The thickness of the material is 50 μm, and the adhesive layer adopts the above-mentioned viscoelastic anti-mold and anti-corrosion adhesive material with a thickness of 0.5 mm; an isolation layer is provided on the other side of the adhesive layer, and the isolation layer adopts a PET release film with a thickness of 50 μm.

[0064] The preparation method of the viscoe...

Embodiment 3

[0066] The viscoelastic anti-mildew and anti-corrosion glue used for buried pipelines in this embodiment consists of the following components in parts by mass:

[0067]

[0068] The preparation method of the viscoelastic anti-mildew and anti-corrosion adhesive used for buried pipelines in this embodiment is the same as that in Embodiment 1.

[0069] The viscoelastic anti-mildew and anti-corrosion adhesive tape (the same structure as in Example 1) used for buried pipelines in this embodiment includes a base film layer, on which a glue layer is provided, and the base film layer adopts high-density polyethylene The thickness of the material is 50 μm, and the adhesive layer adopts the above-mentioned viscoelastic anti-mildew and anti-corrosion adhesive material with a thickness of 2 mm; an isolation layer is provided on the other side of the adhesive layer, and the isolation layer adopts a PET release film with a thickness of 80 μm.

[0070] The preparation method of the viscoe...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| shear strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com