Environmentally-friendly water-based rusty antirust coating

A rust-proof, environmentally friendly technology, applied in anti-corrosion coatings, coatings, etc., can solve problems such as poor anti-rust performance, and achieve the effects of reducing capillary action, improving anti-corrosion performance, and increasing density

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

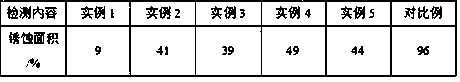

Examples

example 1

[0019] Add polyvinyl alcohol and water into a single-necked flask at a mass ratio of 1:80, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the single-necked flask into a magnetic stirrer with a digital speed measurement and constant temperature at a temperature of 95°C and a speed of Under the condition of 500r / min, heat and stir to dissolve for 50min to obtain polyvinyl alcohol liquid; mix 3-chloro-2 hydroxypropyltrimethylammonium chloride with 20% sodium hydroxide solution in a mass ratio of 1: 1 Place in No. 1 beaker, stir and mix for 60 minutes at a speed of 500r / min to obtain a mixed solution; put xanthate starch and water in a No. 2 beaker at a speed of 500r / min Under the condition of stirring / min, stir and mix for 50min, and then dropwise add a sodium hydroxide solution with a mass fraction of 20% to the No. Add a mixed solution of 0.5 times the mass of xanthate starch, stir and react for 2 hours, then add hydrochloric ...

example 2

[0021]Add polyvinyl alcohol and water into a single-necked flask at a mass ratio of 1:80, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the single-necked flask into a magnetic stirrer with a digital speed measurement and constant temperature at a temperature of 95°C and a speed of Under the condition of 500r / min, heat and stir to dissolve for 50min to obtain polyvinyl alcohol liquid; mix 3-chloro-2 hydroxypropyltrimethylammonium chloride with 20% sodium hydroxide solution in a mass ratio of 1: 1. Place in No. 1 beaker, stir and mix for 60 minutes under the condition of rotating speed of 500r / min to obtain a mixed solution; put diatomaceous earth and tetrabutyl titanate in No. 3 beaker at a mass ratio of 1:40, and Place the No. 3 beaker in an ultrasonic disperser, and under the condition of ultrasonic frequency of 65kHz, mix and ultrasonically soak for 60 minutes to obtain a dispersion, and then filter the dispersion to obtain...

example 3

[0023] Add polyvinyl alcohol and water into a single-necked flask at a mass ratio of 1:80, stir and mix with a glass rod for 30 minutes, let it stand for swelling for 4 hours, and then move the single-necked flask into a magnetic stirrer with a digital speed measurement and constant temperature at a temperature of 95°C and a speed of Under the condition of 500r / min, heat and stir to dissolve for 50min to obtain polyvinyl alcohol liquid; mix 3-chloro-2 hydroxypropyltrimethylammonium chloride with 20% sodium hydroxide solution in a mass ratio of 1: 1 Place in No. 1 beaker, stir and mix for 60 minutes at a speed of 500r / min to obtain a mixed solution; put xanthate starch and water in a No. 2 beaker at a speed of 500r / min Under the condition of stirring / min, stir and mix for 50min, and then dropwise add a sodium hydroxide solution with a mass fraction of 20% to the No. Add a mixed solution of 0.5 times the mass of xanthate starch, stir and react for 2 hours, then add hydrochloric ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

| quality score | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com