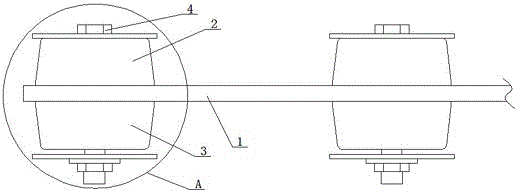

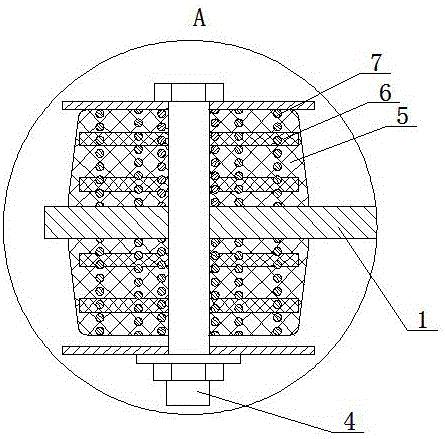

Shock absorber of engine

A technology of shock absorbing device and engine, which is applied in the direction of power device, jet propulsion device, internal combustion propulsion device, etc. It can solve the problems of insufficient hardness of the rubber pad, weak overall, low rigidity, etc., so as to increase the service life and effect, cushioning Good effect and good elasticity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

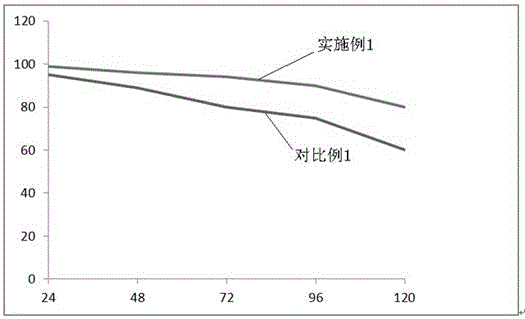

Embodiment 1

[0029] The rubber is mainly prepared from the following raw materials in parts by weight: 100 parts of rubber matrix, 2 parts of accelerator, 12 parts of stearic acid, 8 parts of paraffin, 35 parts of reinforcing agent, 1 part of soap, 2 parts of anti-aging agent, 2 parts of antioxidant, 25 parts of flame retardant, 0.8 part of vulcanizing agent, 4 parts of nano-zinc oxide, 4 parts of nano-silver oxide, 0.8 part of N-(trichloromethylsulfur) phthalimide, polyhexa 0.8 parts of methylene guanidine phosphate, 12 parts of nano-titanium dioxide, 0.3 parts of anti-scorch agent CTP, 0.8 parts of mold release agent, and 1 part of anti-mold agent;

[0030] Wherein the reinforcing agent is composed of the following raw materials in parts by weight: 10 parts of carbon black N330, 12 parts of carbon black N660, 8 parts of hydroxypropyl modified starch / silica composite filler, 5 parts of nano-calcium carbonate;

[0031]The rubber matrix is composed of the following raw materials in parts ...

Embodiment 2

[0041] Another component of rubber is mainly prepared from the following raw materials in parts by weight: 90 parts of rubber matrix, 1.5 parts of accelerator, 10 parts of stearic acid, 7 parts of paraffin, 20 parts of reinforcing agent, 0.5 parts of soap, anti-aging 1 part of antioxidant, 1 part of antioxidant, 20 parts of flame retardant, 0.5 part of vulcanizing agent, 2 parts of nano-zinc oxide, 2 parts of nano-silver oxide, 0.5 part of N-(trichloromethylsulfur) phthalimide part, 0.5 part of polyhexamethylene guanidine phosphate, 10 parts of nano-titanium dioxide, 0.1 part of anti-scorch agent CTP, 0.5 part of release agent, and 0.5 part of fungicide;

[0042] Wherein the reinforcing agent is composed of the following raw materials in parts by weight: 5 parts of carbon black N330, 10 parts of carbon black N660, 5 parts of hydroxypropyl modified starch / silica composite filler;

[0043] The rubber matrix is composed of the following raw materials in parts by weight: 20 part...

Embodiment 3

[0053] The rubber of the third component is mainly prepared from the following raw materials in parts by weight: 110 parts of rubber matrix, 3 parts of accelerator, 15 parts of stearic acid, 10 parts of paraffin, 50 parts of reinforcing agent, 1.5 parts of soap, anti-aging agent 3 parts, 3 parts of antioxidant, 30 parts of flame retardant, 1 part of vulcanizing agent, 6 parts of nano-zinc oxide, 6 parts of nano-silver oxide, 1 part of N-(trichloromethylsulfur) phthalimide , 1 part of polyhexamethylene guanidine phosphate, 15 parts of nano-titanium dioxide, 0.5 part of anti-scorch agent CTP, 1.5 parts of mold release agent, 1.5 parts of anti-mold agent;

[0054] Wherein the reinforcing agent is composed of the following raw materials in parts by weight: 15 parts of carbon black N330, 15 parts of carbon black N660, 10 parts of hydroxypropyl modified starch / silica composite filler, 10 parts of nano calcium carbonate;

[0055] The rubber matrix is composed of the following raw m...

PUM

| Property | Measurement | Unit |

|---|---|---|

| elongation | aaaaa | aaaaa |

| tear strength | aaaaa | aaaaa |

| hardness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com