Production technology of oblique tooth-shaped edge-cut triangular belt

A production process and V-belt technology, which is applied to V-belts, belts/chains/gears, mechanical equipment, etc., can solve problems such as poor fatigue resistance, shortened service life, and easy damage of V-belts. Good elongation resistance, increased service life, and improved service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

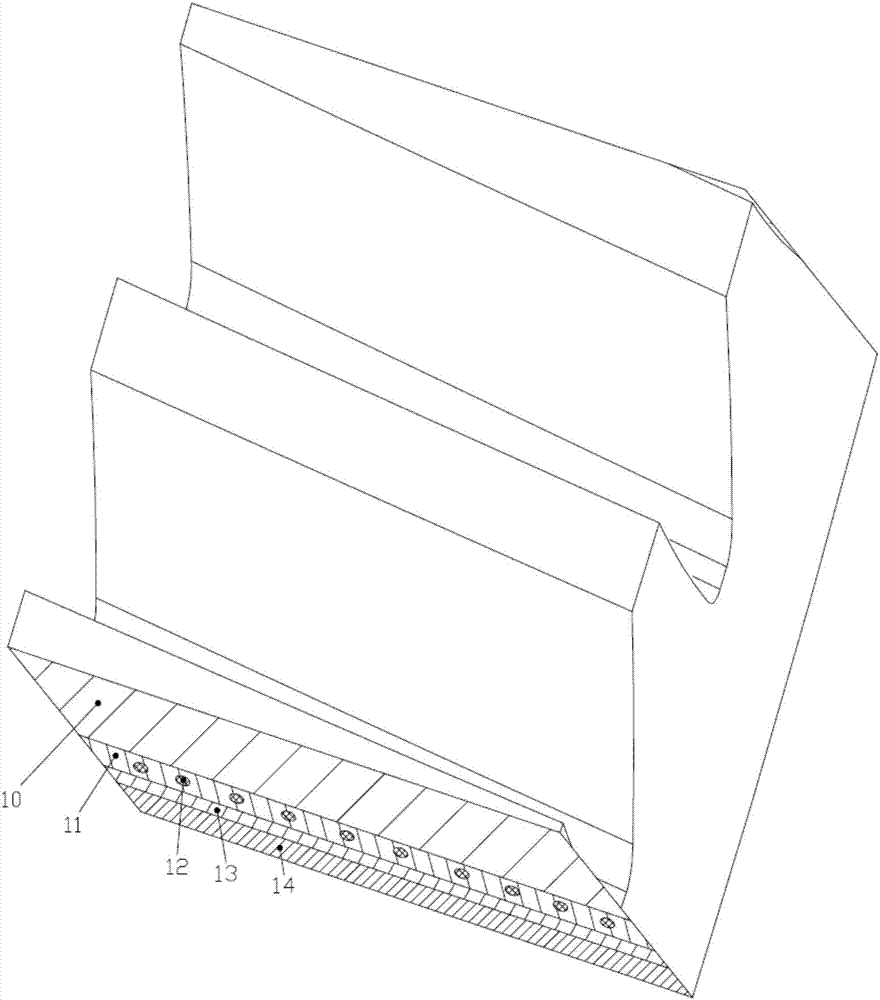

[0022] Below in conjunction with accompanying drawing, the present invention will be further described with specific embodiment, see figure 1 : The production process of the helical-shaped trimmed V-belt, comprising the following steps:

[0023] a, batching: prepare viscose glue, viscose glue, polyester hard cord 12, buffer glue and dipped canvas, described viscose glue and buffer glue adopt the rubber film that this area is conventional and can realize, and wherein the raw material of viscose glue is made of Neoprene, styrene-butadiene rubber, butadiene rubber, magnesium oxide, zinc oxide, carbon black, silica, calcium carbonate, aromatic oil, dibutyl ester, N-isopropyl-N'-phenylene diamine , 2,2,4-trimethyl-1,2-dihydroquinoline, stearic acid, dibenzothiazole disulfide, N-cyclohexylthiophthalimide, cotton powder and polyester fiber composition;

[0024] The parts by weight of each component in the viscose are: neoprene: 85, styrene-butadiene rubber: 10, butadiene rubber: 5,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com