Sisal hemp core steel wire rope for high-speed elevator

A sisal core, medium and high-speed technology, applied in the direction of textile cables, textiles and papermaking, elevators, etc., can solve the problems of poor stability, high elongation, short life, etc., to achieve improved anti-rotation performance, improved service life, and improved The effect of service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

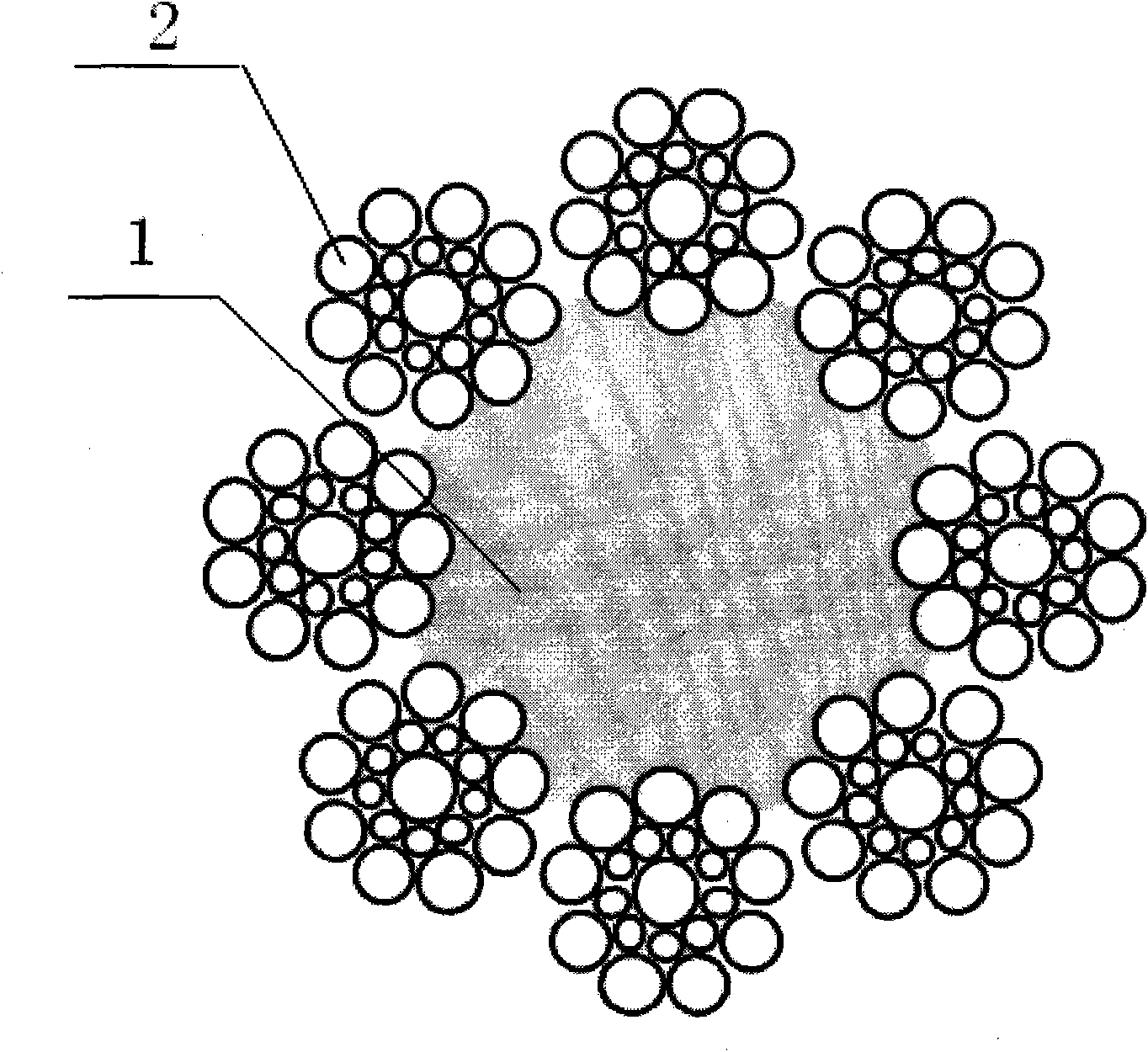

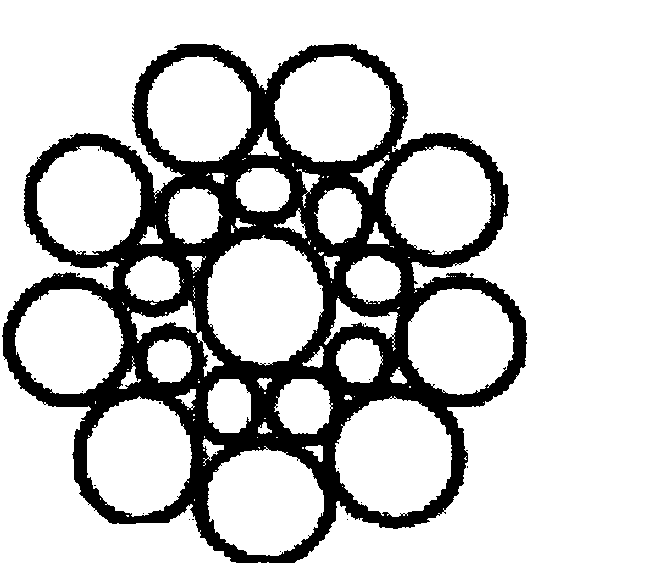

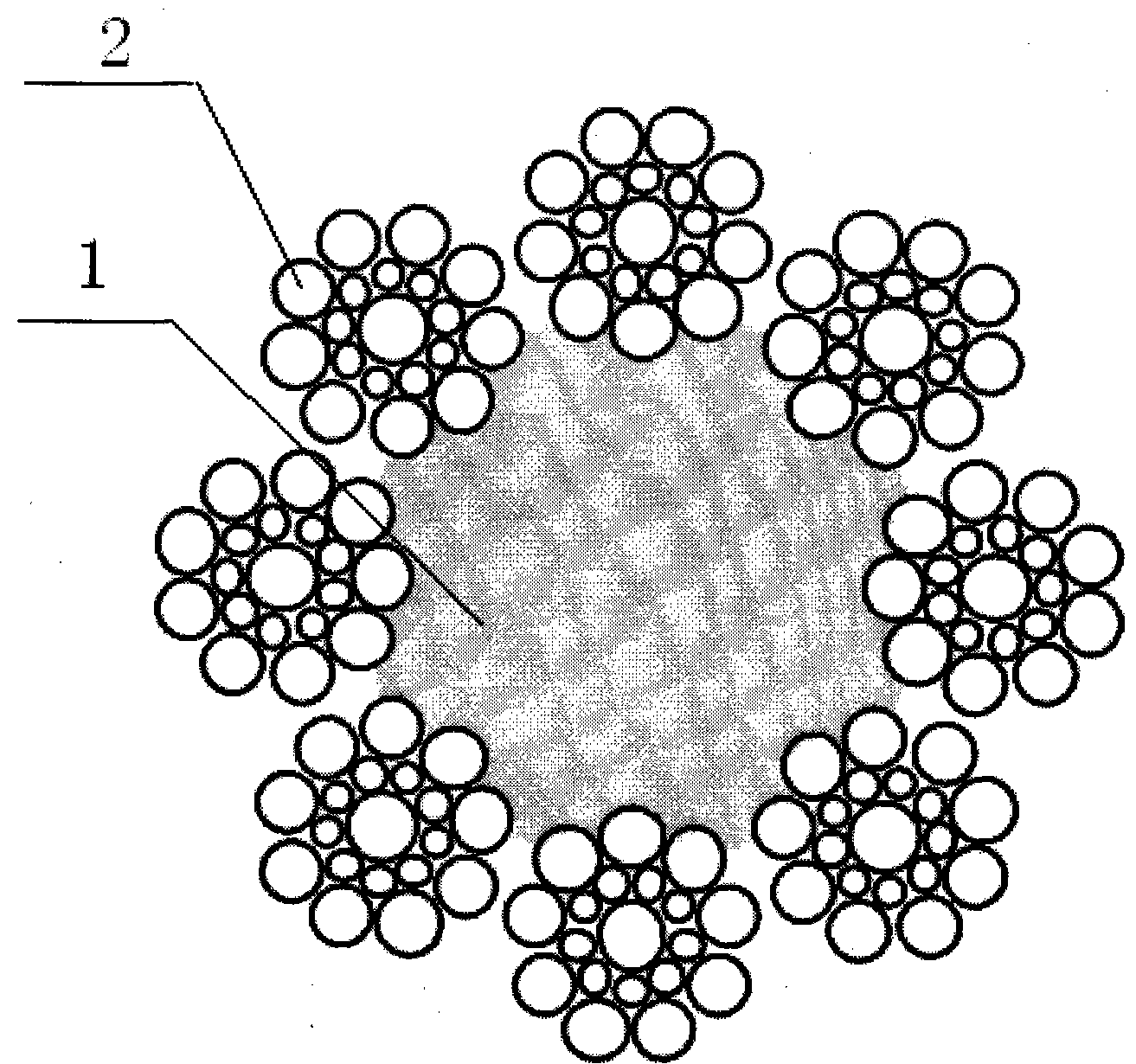

[0024] see figure 1 , figure 2 , a sisal-core steel wire rope for medium and high-speed elevators, comprising a sisal core 1 and an outer layer strand 2, the outer layer strand 2 is evenly wrapped and twisted on the outside of the sisal core 1. The outer layer strand 2 includes 8 steel wire strands, and each steel wire strand of the outer layer strand 2 is a Xilu-style structure, with a central steel wire in the center, and 9 thin steel wires that are evenly wrapped and twisted outside the central steel wire in the inner layer. The layer is 9 thick steel wires that are evenly wrapped and twisted outside the inner layer.

[0025] The preparation method of sisal core steel wire rope for middle and high speed elevator of the present invention comprises the following steps:

[0026] (1) Preparation of the sisal core 1: the hemp yarn is twisted at the same time by a strand to make the sisal core 1;

[0027] (2) Preparation of the outer layer strand 2: Arrange the steel wires on...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com