Opposite pulling type anchor rods for gob-side entrydriving small coal pillar and support method thereof

A technology for small coal pillars and bolts, which is used in the installation of bolts, earth-moving drilling, mining equipment, etc., can solve the inconsistency between the support system and the deformation of the coal pillar, the large deformation characteristics are not considered, and the failure of the support structure is broken. and other issues, to achieve the effect of strong promotion and application value, strong practicability, and ensuring safety and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

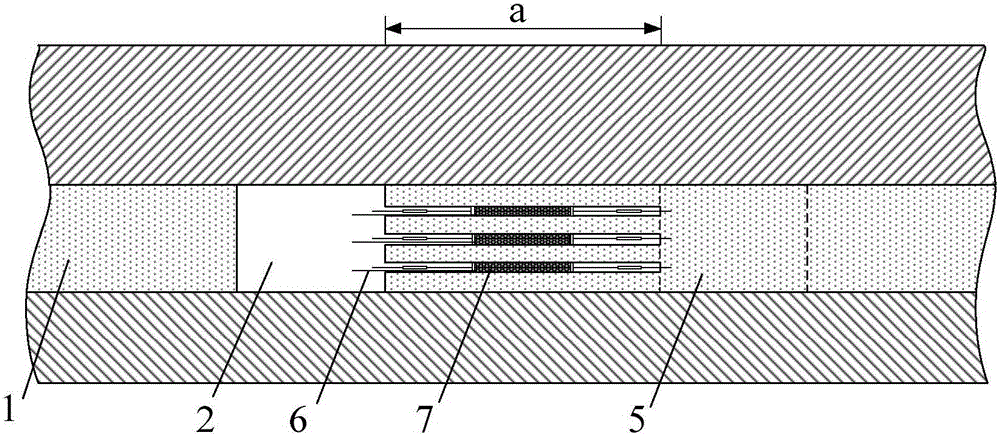

[0020] like Figure 5 As shown, a pair-pull type bolt used for small coal pillars in goaf excavation, which consists of an intermediate tie rod 15, two rubber stopper valves 17 sleeved on the middle tie rod 15, and symmetrically connected to both ends of the middle tie rod 15. Large deformation device, and supporting nut 9 and tray 10;

[0021] Described large deformation device comprises sleeve 13, high-strength compression spring 16, fastening bolt 12 and connector 14; Image 6 As shown, the bottom end of the above-mentioned sleeve 13 is provided with a back cover with a through hole 18, and the open end is provided with an internal thread; as Figure 7 As shown, one end of the above-mentioned connector 14 is provided with an external thread connected with the open end of the sleeve 13, and the other end is provided with an internal thread connected with the middle tie rod 15; the above-mentioned high-strength compression spring 16 is loaded into the sleeve 13, and then the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com