Rotary electro-osmotic sludge dewatering system and method for oxidative degradation of organic matters

A technology of oxidative degradation and sludge dehydration, which is applied in the direction of oxidation treatment of sludge, dehydration/drying/thickened sludge treatment, etc. It can solve the problems of complicated process flow, uneven water distribution of mud cake cathode and anode, and reduced contact area. , to achieve the effect of improving the degradation effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

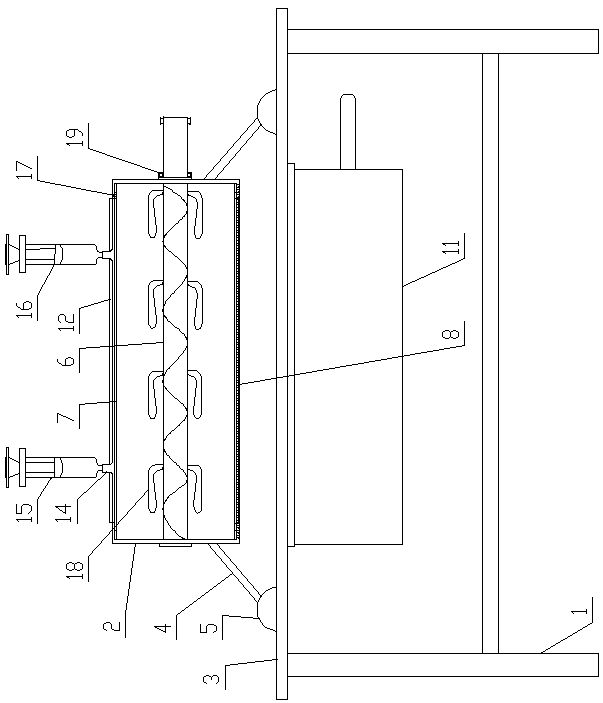

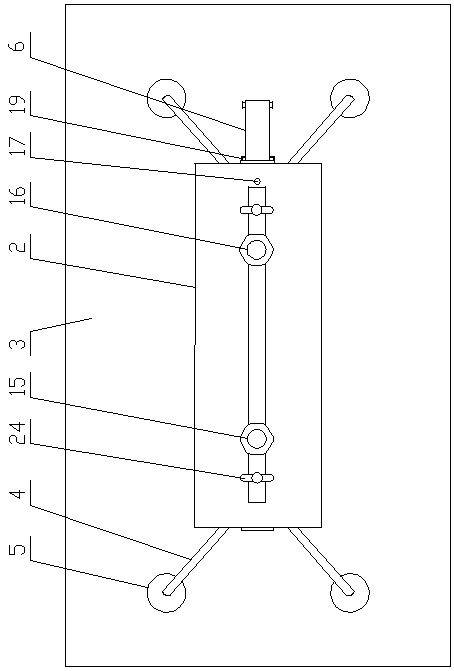

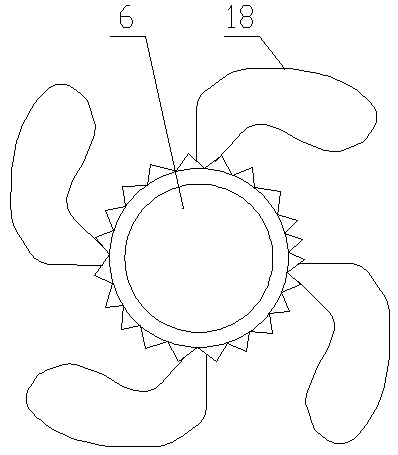

[0050] Such as Figure 1-Figure 5 As shown, the rotary electroosmotic sludge dewatering system for oxidatively degrading organic matter of the present invention includes an automatic reverse polarity constant voltage and constant current power supply, an adjustable speed electric drive device, an underframe 1 and a cylindrical electroosmotic reactor 2, The bottom frame 1 is provided with a platen 3, and the platen 3 is provided with four diagonal struts 4, and the lower ends of the four diagonal struts 4 are hinged on the platen 3 through a detachable hinge 5, and the four detachable hinges 5 Located on the four vertices of a rectangle, the center line of the electroosmotic reactor 2 is horizontally arranged along the left and right directions, and the upper ends of the two diagonal braces 4 on the left are fixedly connected to the left end surface of the electroosmotic reactor 2, and the upper ends of the two diagonal braces 4 on the right The upper ends of the two diagonal s...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com