Liquefied soil foundation quake-proof road-bridge transition section structure of ballastless track of high-speed railway

A ballastless track and high-speed railway technology, applied in the direction of tracks, roads, bridges, etc., can solve the problems affecting the high-speed, safe and comfortable running state of the train, the increase of the interaction force between the train and the line structure, and the inconsistent settlement of the embankment and the abutment, etc. problems, to achieve the effect of reducing poor mechanical properties, comfortable driving goals, and smooth driving goals

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

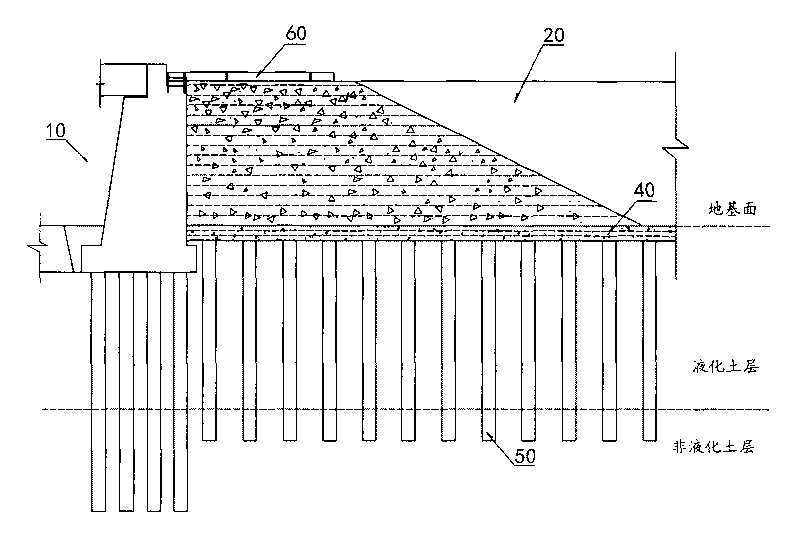

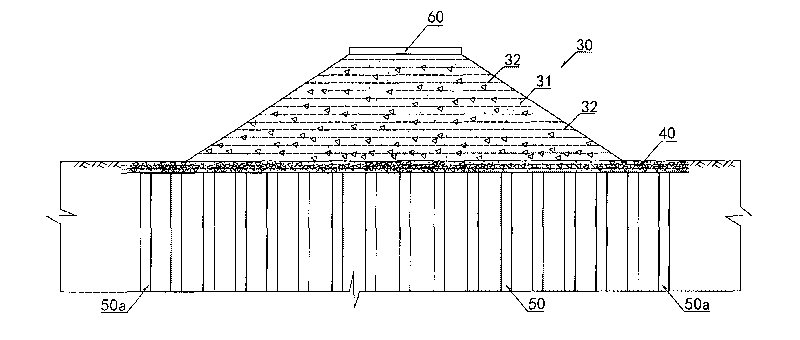

[0018] refer to figure 1 and figure 2 , the structure of the seismic road-bridge transition section of the liquefied soil foundation of the ballastless track of the high-speed railway, including a concrete abutment 10 and an earthen roadbed 20, and between the concrete abutment 10 and the earthen roadbed 20, there is a wedge-shaped longitudinal section and a regular trapezoidal cross-section. Reinforced graded crushed stone transition section 30. Rows of reinforcement piles 50 are arranged vertically and horizontally in the liquefied soil foundation below, and the pile ends of each reinforcement pile 50 go through the liquefied soil layer of the foundation and go deep into the non-liquefied soil layer. Between the foundation surface and the top of the reinforced pile 50, a cement-graded crushed stone reinforced cushion 40 is laid. refer to figure 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com