Ceramic tile adhesive and preparation method thereof

A technology for tile adhesive and bio-adhesive, applied in the field of building materials, can solve the problems that rarely meet the construction conditions of the thin-layer method, high requirements on the flatness of the base layer, and high cost, achieve excellent anti-slip performance, improve anti-slip ability, enhance The effect of adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

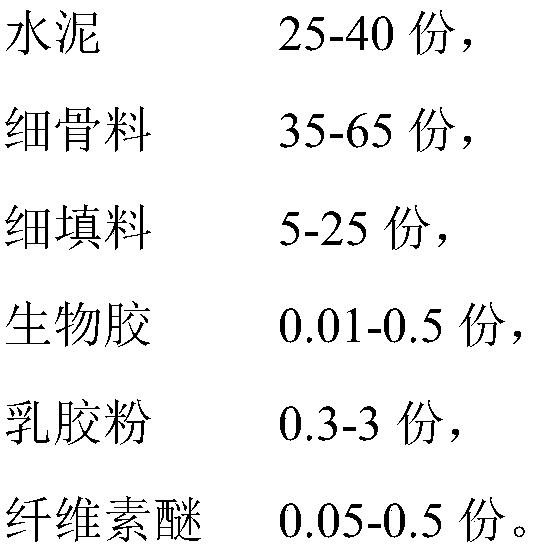

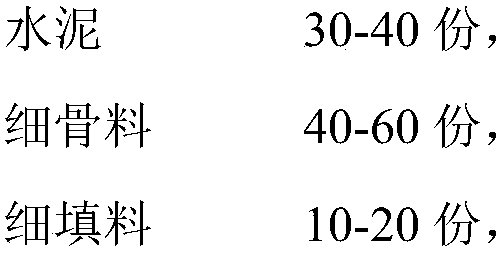

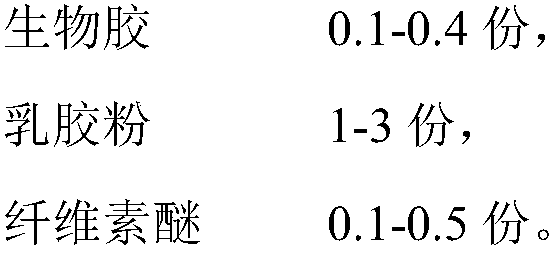

Method used

Image

Examples

Embodiment 1

[0034] Prepare the raw materials according to the following formula: Ordinary Portland cement 300g, 50-100 mesh river sand 500g, 800 mesh mineral powder 80, 200 mesh stone powder 100g, Diutin 0.2g, latex powder 10g, cellulose ether (viscosity 10W) 2g, 4g of inorganic fiber, 3.8g of calcium formate; mix and stir the above-mentioned raw materials to obtain tile adhesive.

Embodiment 2

[0036] Prepare each raw material according to the following formula: Portland cement 340g, 50-100 mesh river sand 400g, 80-120 mesh machine-made sand 200g, 800 mesh mineral powder 45g, xanthan gum 0.3g, latex powder 7.7g, cellulose ether ( Viscosity (10W) 3g, inorganic fiber 3g, calcium formate 1g; mix and stir the above-mentioned raw materials to obtain tile adhesive.

Embodiment 3

[0038] Prepare the raw materials according to the following formula: Portland cement 250g, 80-120 mesh machine-made sand 150g, secondary fly ash 80g, Brunei gum 0.1g, Wenlun gum 0.1g, latex powder 15g, cellulose ether (viscosity 10W ) 2g, inorganic fiber 2.6g; the tile adhesive is obtained after mixing and stirring the above-mentioned raw materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com