Low-carbon environment-friendly flexible large-plate ceramic tile adhesive

A low-carbon, environmentally friendly, tile adhesive technology, applied in the field of building materials, to achieve strong water resistance, low price, improved water resistance and flexibility

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

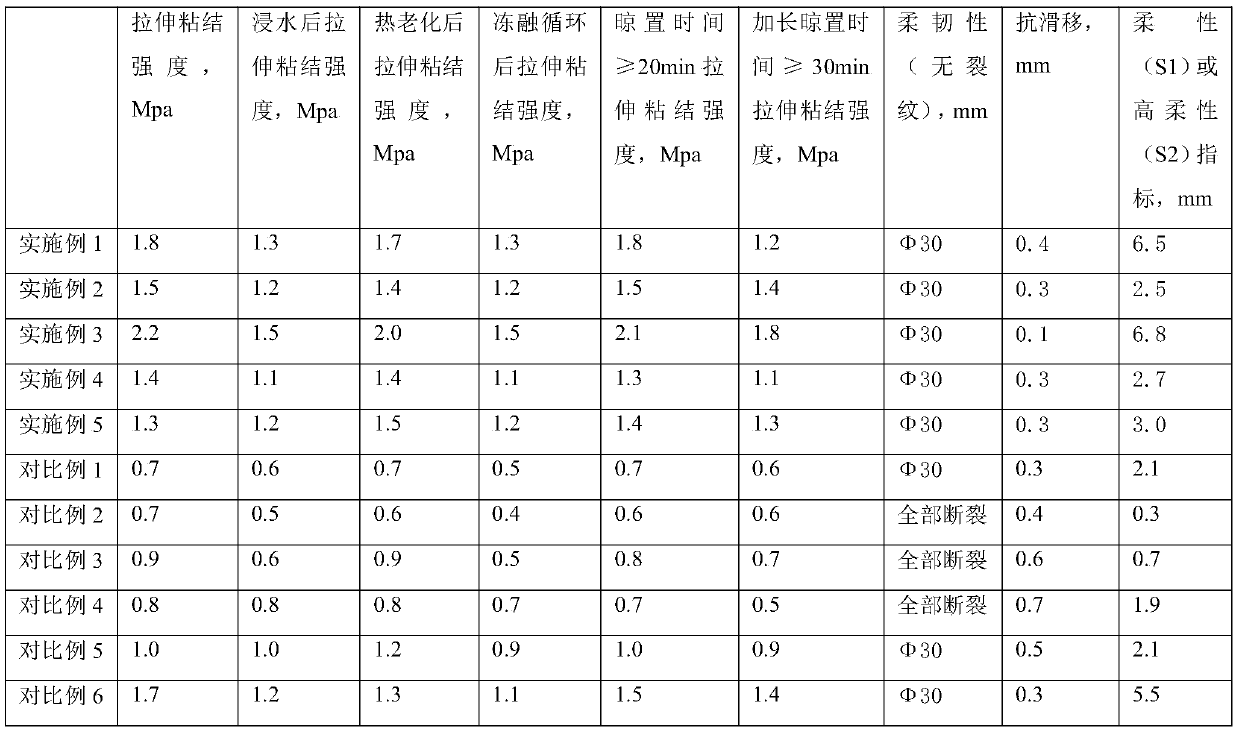

Examples

Embodiment 1

[0029] A low-carbon environment-friendly flexible large-slab tile adhesive, comprising the following components by weight: 10 parts of pII52.5 ordinary silicon cement, 30 parts of mineral powder, 20 parts of coarse quartz sand, 15 parts of fine quartz sand, and 2 parts of negative ion powder , 15 parts of modified redispersible latex powder, 3 parts of VAE redispersible latex powder, 0.36 part of modified cellulose ether, 0.04 part of starch ether, 1 part of calcium silicate, 0.6 part of metakaolin, Na 2 SO 4 3 copies.

[0030] In this embodiment, the particle size of the mineral powder is 4 μm, the specification of the coarse quartz sand is 30-70 mesh, and the specification of the fine quartz sand is 70-180 mesh.

[0031] The modified redispersible latex powder is prepared by the following method: Weigh the emulsifier OP-10 and polyvinyl alcohol in water to form a uniform solution according to the weight ratio, add calcium carbonate and zinc oxide while vigorously stirring, ...

Embodiment 2

[0035] A low-carbon environment-friendly flexible large-slab tile adhesive, comprising the following components by weight: 25 parts of pII52.5 ordinary silicon cement, 15 parts of mineral powder, 23.04 parts of coarse quartz sand, 15 parts of fine quartz sand, and 1 part of negative ion powder , 2 parts of modified redispersible latex powder, 15 parts of VAE redispersible latex powder, 0.9 part of modified cellulose ether, 0.06 part of starch ether, 0.5 part of triisopropanolamine, 1.5 parts of bentonite, Ca(OH) 2 1 serving.

[0036] In this embodiment, the particle size of the mineral powder is 1 μm.

[0037] The modified redispersible latex powder is prepared by the following method: Weigh the emulsifier OP-10 and polyvinyl alcohol in water to form a uniform solution according to the weight ratio, add calcium carbonate and zinc oxide while vigorously stirring, and spray dry to make a modified As a modifier, the modifier and the redispersible latex powder are uniformly mixed...

Embodiment 3

[0041] A low-carbon environment-friendly flexible large-slab tile adhesive, comprising the following components by weight: 15 parts of pII52.5 ordinary silicon cement, 25 parts of mineral powder, 22.92 parts of coarse quartz sand, 18.8 parts of fine quartz sand, and 1.5 parts of negative ion powder , 10 parts of modified redispersible latex powder, 2 parts of VAE redispersible latex powder, 0.6 part of modified cellulose ether, 0.08 part of starch ether, 0.8 part of calcium formate, 1.3 part of metakaolin, NaHCO 3 2 servings.

[0042] In this embodiment, the particle size of the mineral powder is 3 μm.

[0043] The modified redispersible latex powder is prepared by the following method: Weigh the emulsifier OP-10 and polyvinyl alcohol in water to form a uniform solution according to the mass ratio, add calcium carbonate and zinc oxide while vigorously stirring, and spray dry to make a modified As a modifier, the modifier and the redispersible latex powder are uniformly mixed ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com