Control method for forward slipping coefficient of hot rolled silicon steel

A control method and forward sliding technology, applied in the rolling mill control device, metal rolling, metal rolling, etc., can solve the problems of steel drawing, poor rolling adaptability, strip stacking, etc., to reduce the accumulation of loopers, solve the The effect of rolling instability and improved adaptability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

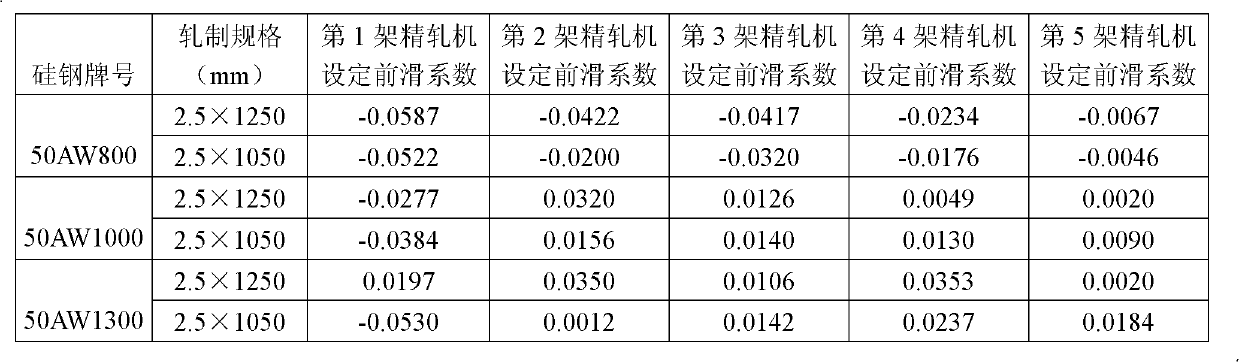

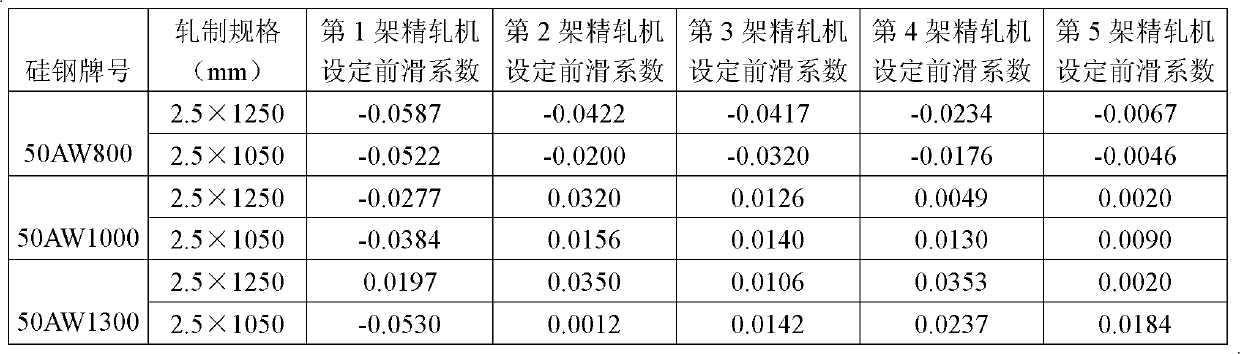

Embodiment 1

[0020] The grade of silicon steel is 50AW800, and the rolling specification is 2.5×1050mm. F1 sets the forward slip coefficient to -0.0522, F2 sets the forward slip coefficient to -0.0200, F3 sets the forward slip coefficient to -0.0320, F4 sets the forward slip coefficient to -0.0176, and F5 sets the forward slip coefficient to -0.0046.

[0021] Input the set forward slip coefficient of each finishing mill into the finishing rolling model control program respectively. When the finishing mill rolls the first piece of silicon steel, the finishing mills of each stand use the set forward slip coefficient, and the forward slide coefficient used for the silicon steel of the brand and specification rolled later is determined according to the actual loop condition of the previous piece of silicon steel. Adjustment, the model self-learning program automatically uses the adjusted forward slip coefficient of the previous silicon steel as the forward slip coefficient of the next silicon ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com