Super-hard anti-slip terrace material

A floor material, ultra-hard anti-slip technology, applied in anti-corrosion coatings, polyester coatings, epoxy resin coatings, etc., can solve the problems of easy agglomeration, drying time, poor hardness, etc., and achieve good anti-slip and simple construction technology.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

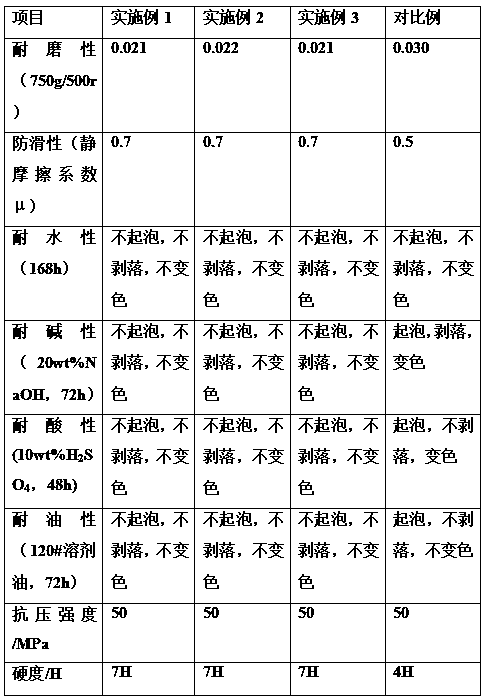

Embodiment 1

[0013] The superhard non-slip floor material, the coating is composed of component A and component B, and component A includes the following raw materials: in parts by weight, 40 parts of bisphenol A epoxy resin, 1 part of color paste, 15 parts of 600 mesh heavy calcium powder, 15 parts of 600 mesh quartz powder, 5 parts of 600 mesh mica powder, 5 parts of phenyl glycidyl ether, 5 parts of butyl glycidyl ether, 0.5 part of salicylic acid, 0.1 part of 300 mesh zirconium dioxide 1 part, EFKA2040: 0.1 part, EFKA 3650: 0.2 part, EFKA 4330: 0.2 part; Component B includes the following raw materials: by weight, 40 parts of modified polyamide, 1 part of methyldiethanolamine;

[0014] The mass ratio of the A component to the B component is 5:1.

Embodiment 2

[0016] The superhard non-slip floor material, the coating is composed of component A and component B, component A includes the following raw materials: in parts by weight, 45 parts of bisphenol A epoxy resin, 3 parts of color paste, 18 parts of 600 mesh heavy calcium powder, 18 parts of 600 mesh quartz powder, 7 parts of 600 mesh mica powder, 7 parts of phenyl glycidyl ether, 7 parts of butyl glycidyl ether, 1 part of salicylic acid, 0.3 parts of 300 mesh zirconium dioxide 0.2 parts of EFKA2040, 0.3 parts of EFKA 3650, 0.3 parts of EFKA 4330, 20 parts of short-oil alkyd resin, 0.2 parts of BYK 9077 dispersant; component B includes the following raw materials: by weight, 45 parts of modified polyamide , 2 parts of methyldiethanolamine;

[0017] The mass ratio of the A component to the B component is 5:1.

Embodiment 3

[0019] The superhard non-slip floor material, the coating is composed of component A and component B, component A includes the following raw materials: in parts by weight, 50 parts of bisphenol A epoxy resin, 5 parts of color paste, 20 parts of 600 mesh heavy calcium powder, 20 parts of 600 mesh quartz powder, 10 parts of 600 mesh mica powder, 10 parts of phenyl glycidyl ether, 10 parts of butyl glycidyl ether, 3 parts of salicylic acid, 0.5 parts of 300 mesh zirconium dioxide 0.3 parts of EFKA 2040, 0.5 parts of EFKA 3650, 0.6 parts of EFKA 4330, 25 parts of short oil alkyd resin, 0.5 parts of BYK 9077 dispersant; component B includes the following raw materials: by weight, modified polyamide 50 part, 3 parts of methyldiethanolamine;

[0020] The mass ratio of the A component to the B component is 5:1.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com