Coordinated Speed Control Method of Plate Mill and Conical Roller Table

A synergistic control, tapered roller technology, applied in the field of metal pressure processing, can solve the problems affecting the surface quality of the plate surface, such as the service life of the roller table and the difference in linear speed, and achieve the effect of improving the surface quality, increasing the service life and reducing the workload.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0051] According to the rolling schedule set by the two-level model system of the rolling mill, it can be known that the parameters of the 10th pass of rolling a certain rolling stock are as follows:

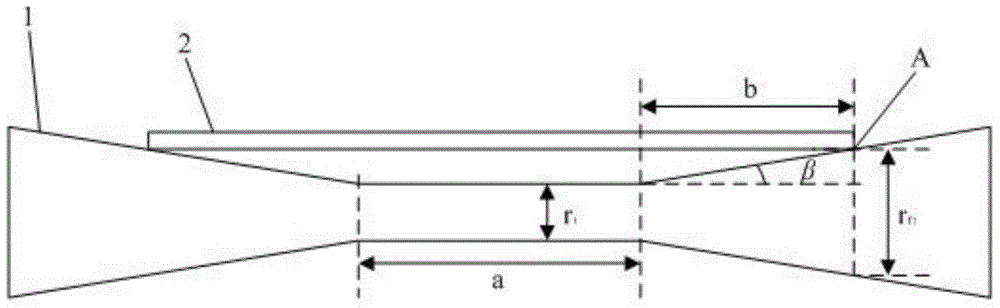

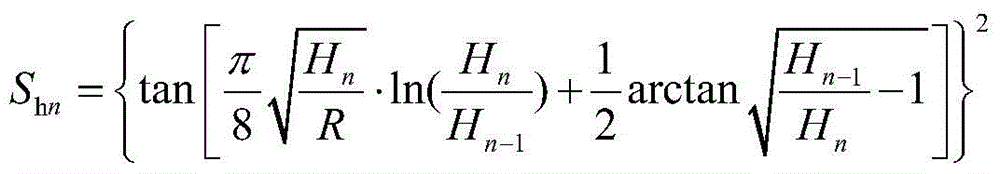

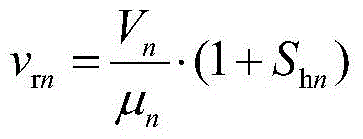

[0052] The entrance thickness of the 10th rolling pass is H 9 =193.4 mm; the exit thickness of the 10th pass of rolling is H 10 =161.6 mm; the length of the entrance of the 10th pass of rolling is L 9 =10900 mm; the exit length of the 10th pass of rolling is L 10 = 13000 mm; the entrance width of the 10th pass of rolling is W 9 =1715 mm; the exit width of the 10th pass of rolling is W 10 = 1727mm; the line speed of the work roll of the rolling mill in the 10th pass is V 10 =2000 mm / s, this value is a changing value within one pass, the PLC control system real-time according to V 10 Calculate the speed of the tapered roller, when V 10 When changing, the speed of the tapered roller table also changes accordingly. Here, for the convenience of calculation, it is set as a fixe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com