A method of thread processing using a two-for-one twister

A technology of double twisting machine and silk thread, applied in the field of textile processing, can solve the problems of the appearance and style of the fabric failing to meet customer or design requirements, the rising cost of the fabric, and the difference in the twist of the double twist design.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0029] The technical solution of the present invention will be described in further detail below in conjunction with the accompanying drawings and embodiments, and the following embodiments do not constitute a limitation of the present invention.

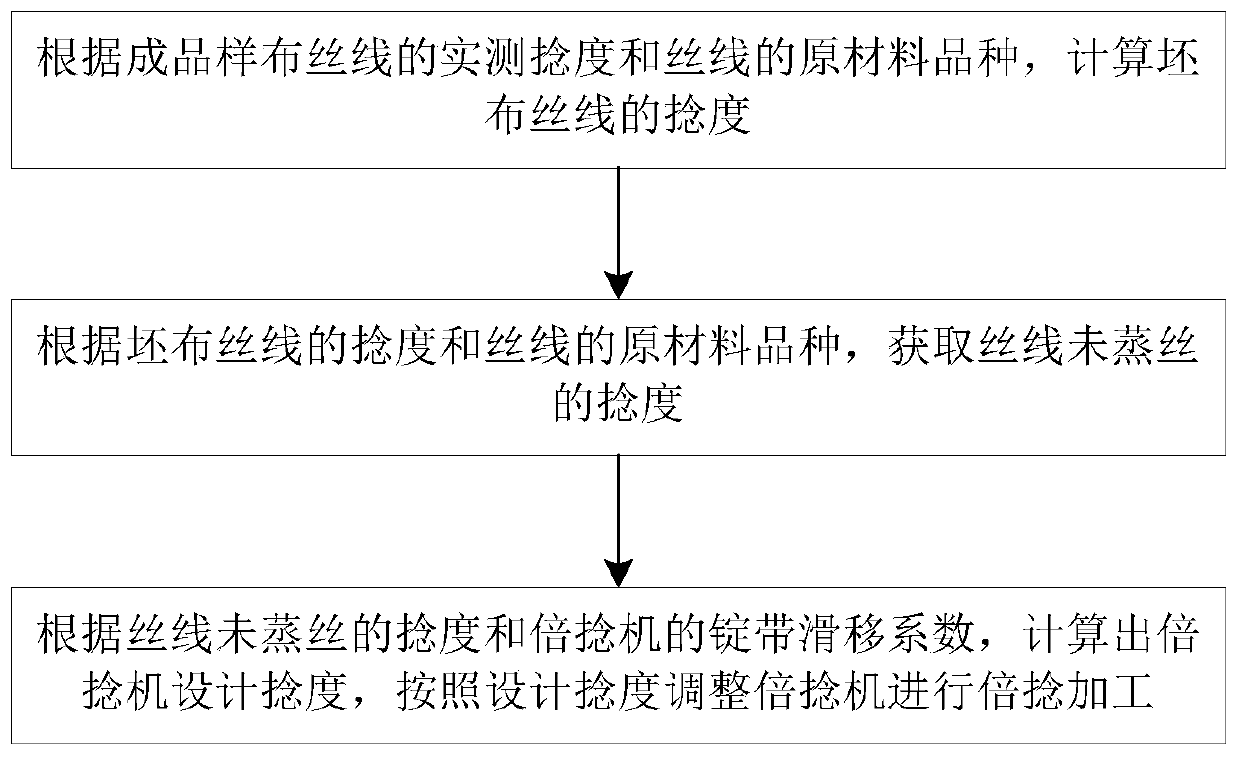

[0030] Such as figure 1 As shown, this technical solution proposes a kind of embodiment that adopts two-for-one twister to carry out the method for thread processing, comprises the steps:

[0031] Step 1. Calculate the twist of the gray cloth silk thread according to the measured twist of the finished sample cloth silk thread and the raw material type of the silk thread.

[0032] In engineering practice, the measured twist of the finished sample cloth thread is related to the twist of the gray cloth thread. The gray cloth can only be called a finished product after printing and dyeing. There is a printing and dyeing shrinkage in the printing and dyeing process, which will cause the measured twist of the finished product to be differ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com