Foaming type thermoplastic polyurethane particles and preparation method thereof

A thermoplastic polyurethane, foaming technology, applied in the field of foaming materials and its preparation, can solve the problems of large particle gap, large particle size, difficult feeding, etc., and achieves low dimensional shrinkage, excellent dimensional stability, and easy feeding. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

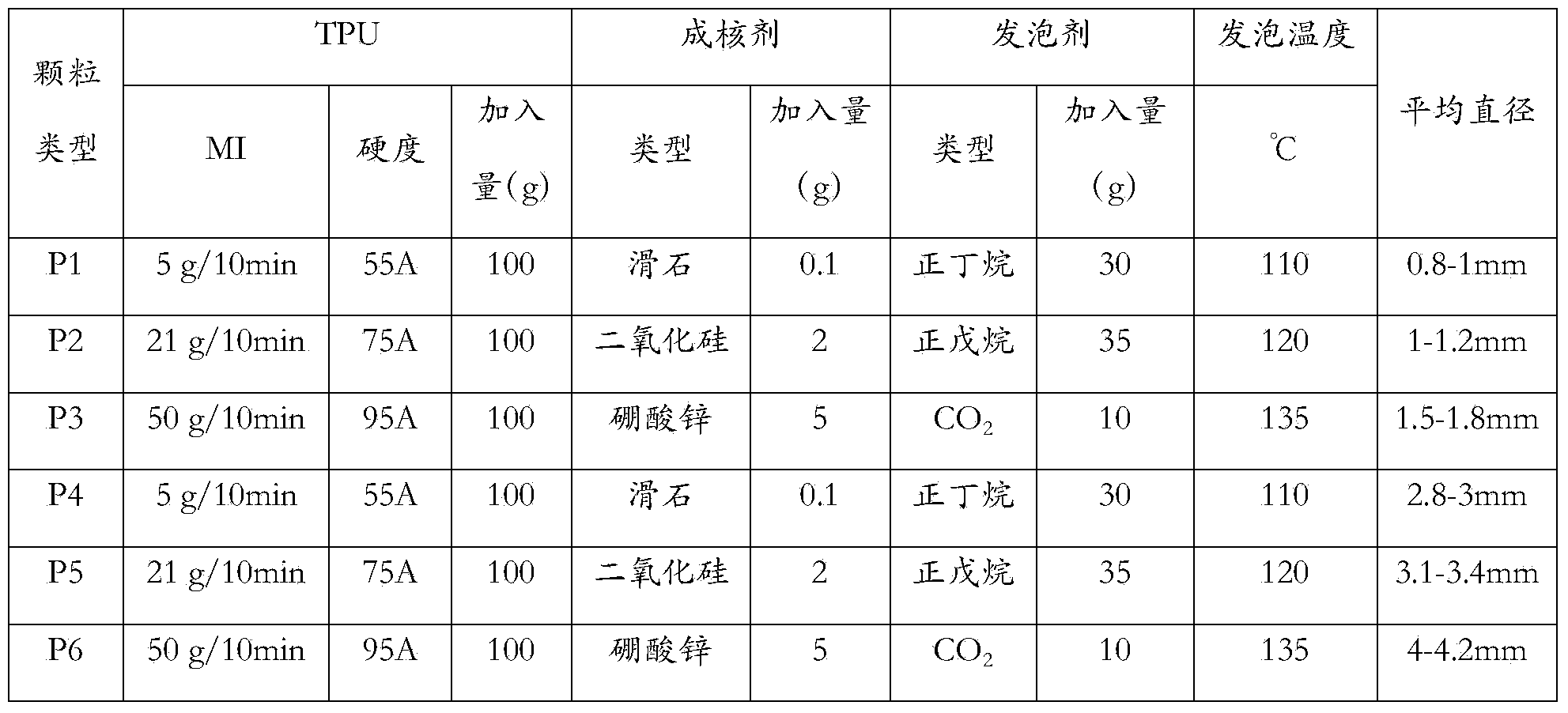

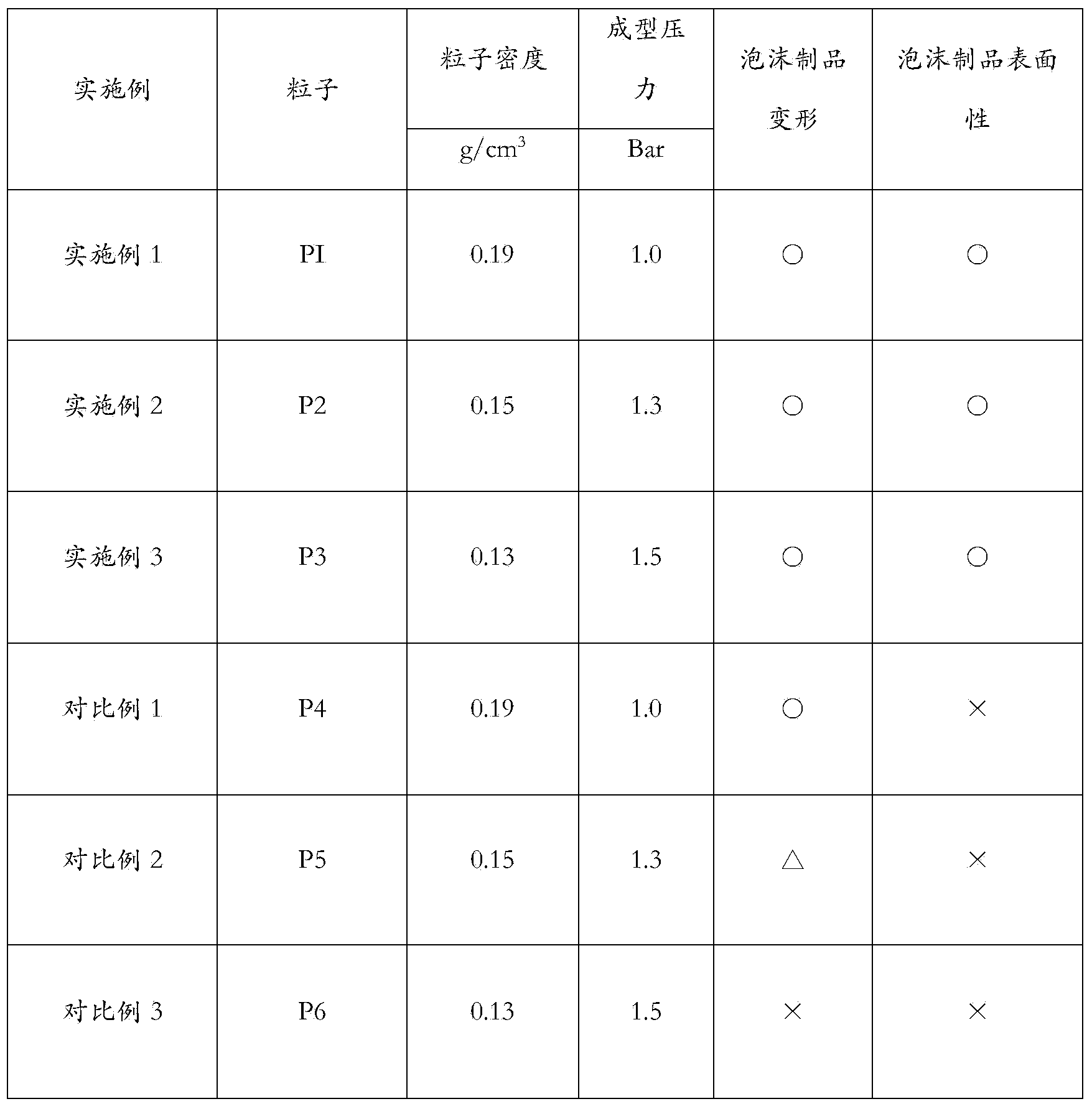

[0033] Mix 100 parts of TPU particles with a MI of 5g / 10min and a hardness of 55A and 0.1g of talc through a high-speed mixer and put them into a twin-screw extrusion for melt mixing. MI is the melt index. The molten kneaded product was extruded from the die head of the extruder and subjected to underwater granulation to obtain thermoplastic polyurethane beads. The die used had 12 holes, each with a diameter of 0.6 mm, and the resulting thermoplastic polyurethane beads had an average diameter of 0.8-1.0 mm.

[0034] 100g of thermoplastic polyurethane beads and 400g of water were added to a 10L autoclave, and 30g of n-butane blowing agent was added while stirring. The autoclave was heated to 110°C, and then kept at this temperature for 20 minutes, the discharge valve at the bottom of the autoclave was opened, and the mixed liquid in the autoclave was discharged into the atmosphere, thereby obtaining foamed thermoplastic polyurethane particles P1. The obtained foamed thermoplas...

Embodiment 2

[0037] 100 parts of TPU granules with an MI of 21g / 10min and a hardness of 75A and 2g of silicon dioxide were uniformly mixed by a high-speed mixer and then put into twin-screw extrusion for melt mixing. The molten kneaded product was extruded from the die head of the extruder for underwater granulation to obtain thermoplastic polyurethane beads. The die used had 12 holes, each with a diameter of 0.8 mm, and the resulting thermoplastic polyurethane beads had a diameter of 1.0-1.2 m.

[0038] 100g of thermoplastic polyurethane beads and 400g of water were added to a 10L autoclave, and 35g of n-pentane blowing agent was added while stirring. Raise the temperature of the autoclave to 120°C and keep it at this temperature for 20 minutes, open the discharge valve at the bottom of the autoclave, and discharge the mixed liquid in the autoclave to the atmosphere, thereby obtaining foamable thermoplastic polyurethane particles P2. The particle density of foamed thermoplastic polyureth...

Embodiment 3

[0041] 100 parts of TPU granules with an MI of 50g / 10min and a hardness of 95A and 5g of zinc borate were mixed uniformly by a high-speed mixer and then put into a twin-screw extrusion for melt mixing. The molten kneaded product was extruded from the die head of the extruder for underwater granulation to obtain thermoplastic polyurethane beads. The die used had 12 holes each with a diameter of 1.2 mm, resulting in thermoplastic polyurethane beads with a diameter of 1.5-1.8 mm.

[0042] 100g of thermoplastic polyurethane beads and 400g of water were added into a 10L autoclave, and 10g of carbon dioxide blowing agent was added while stirring. The autoclave was heated to 135°C, and then kept at this temperature for 20 minutes, the discharge valve at the bottom of the autoclave was opened, and the mixed liquid in the autoclave was discharged into the atmosphere, thereby obtaining foamed thermoplastic polyurethane particles P3. The obtained expanded thermoplastic polyurethane part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| The average diameter | aaaaa | aaaaa |

| Density | aaaaa | aaaaa |

| The average diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com