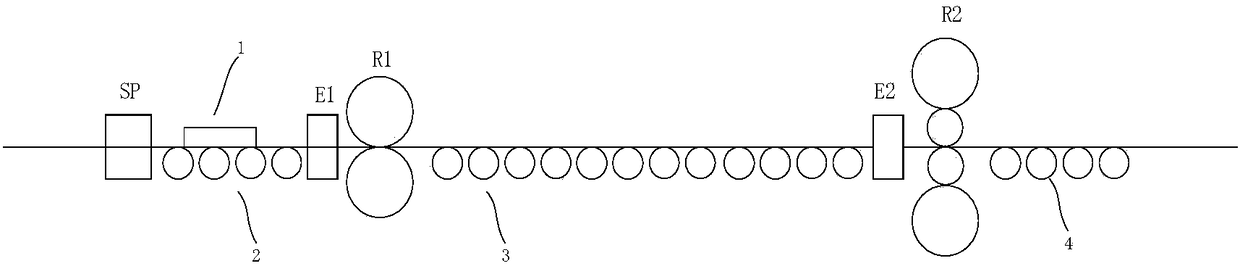

Optimizing setting method for speed of vertical roll in hot continuous rolling and rough rolling forward pass rolling process

A rolling process, optimized setting technology, applied in metal rolling, roll speed control, metal rolling and other directions, can solve the problems of slab edge cracks, vertical roll mill power outages, etc., to prevent power outages and improve initial performance. Effects of speed matching, improved stability and product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

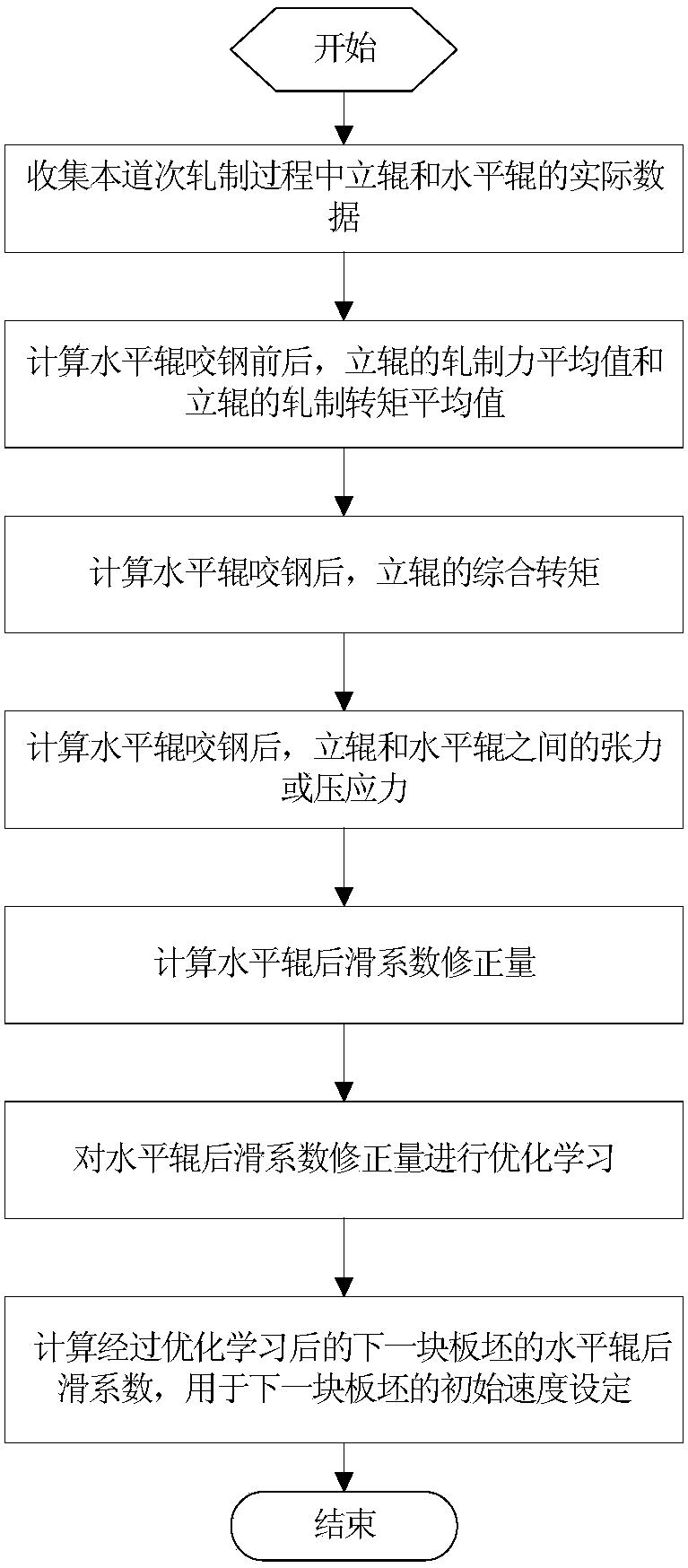

Method used

Image

Examples

Embodiment 1

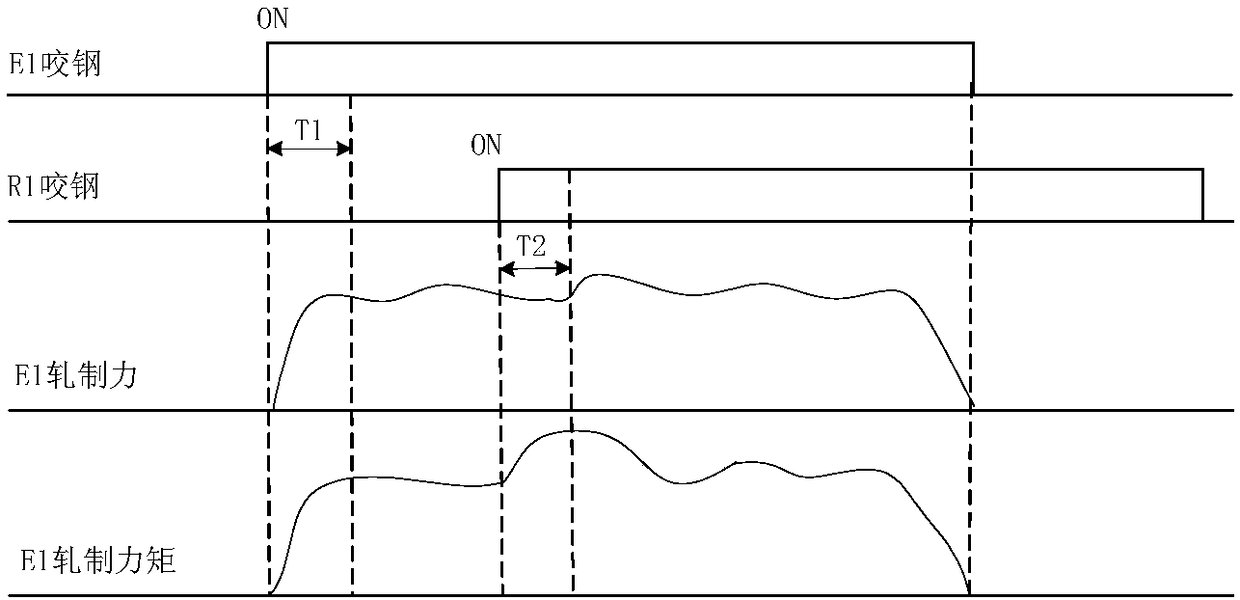

[0076] Such as Figure 5a As shown, when E1-R1 is rolling for the first pass, the learning function of horizontal roll back slip is not put into use. It can be seen from the figure that after the horizontal roll bites the steel, the torque of the vertical roll increases gradually, with a maximum increase of 67.46kNm. According to the above steps, the learning of the backslip coefficient of the horizontal roller is carried out, and the specific implementation is as follows:

[0077] (1) Collect the actual data of rolling in this pass.

[0078] (2) T1 is taken as 1.4, and the average value F of E1 rolling force between E1 biting steel T1 second and R1 biting steel is calculated AVE1 3102kN, average rolling torque G AVE1 is 87.4kNm; T2 is taken as 1.2, and the average rolling force F of E1 within T2 seconds after R1 bites the steel is calculated AVE2 3095kN, average rolling torque G AVE2 It is 125.8kNm.

[0079] (3) due to G AVE2 >G AVE1 , then calculate the maximum value...

Embodiment 2

[0086] Such as Figure 6a As shown, during the third rolling pass of E1-R1, the learning function of backslip of the horizontal roll was not put into use. It can be seen from the figure that after the horizontal roll bites the steel, the torque of the vertical roll decreases gradually, the maximum reduction is 121kNm, and the minimum torque of the vertical roll is -70kNm, that is, the horizontal roll is dragging the vertical roll. According to the above steps, the corrected value of the backslip coefficient of the horizontal roller is calculated to be 0.026, and the new backslip coefficient value is 0.859.

[0087] The backsliding coefficient value is used for the initial speed setting of the next slab, and the actual rolling data is as follows Figure 6b As shown, after the horizontal roll bites the steel, the maximum torque of the vertical roll is only reduced by 55kNm, and the minimum torque of the vertical roll is 9kNm, which is no longer a negative value, and the steel p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com