Method and device for compensating cold continuous rolling forward slip value

A technology of forward slip value and compensation value, applied in the field of cold continuous rolling production, can solve the problems of inaccurate forward slip value, inability to guarantee the stability of the rolling process, affecting the quality of strip steel products, etc. The effect of improving calculation accuracy and ensuring the quality of strip steel products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

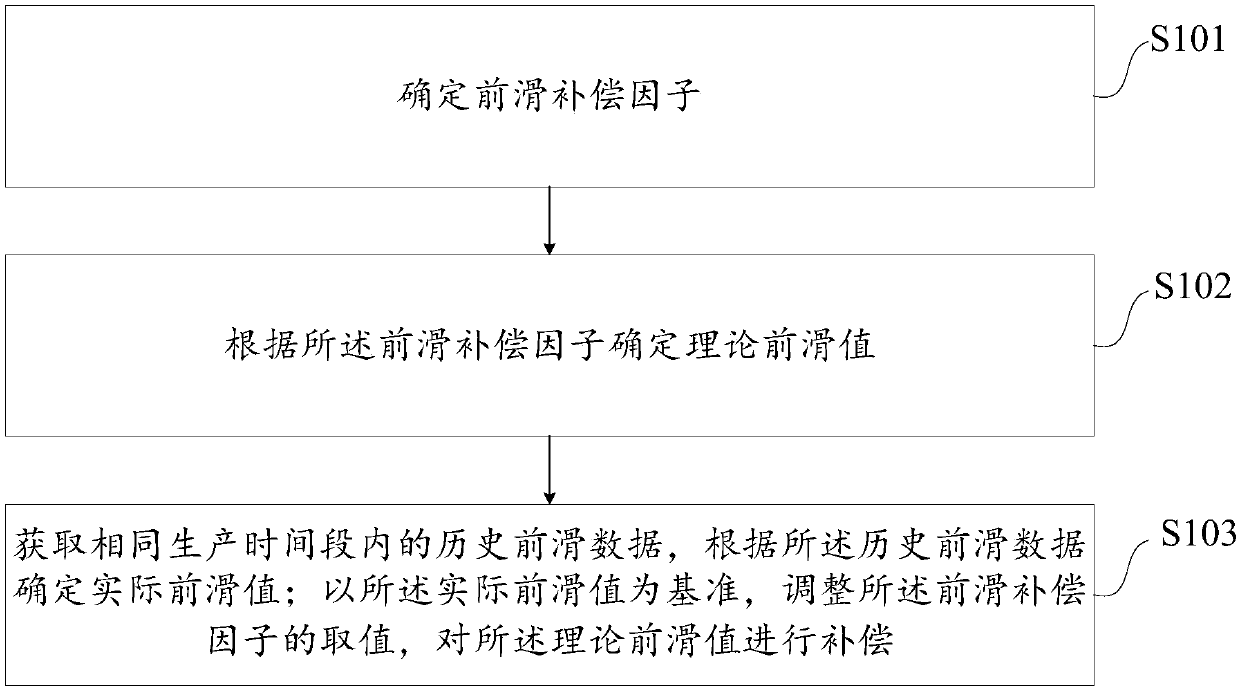

[0040] This embodiment provides a method for compensating the slip value before tandem cold rolling, such as figure 1 As shown, the method includes:

[0041] S101, determine the forward slip compensation factor;

[0042] In this step, in order to be able to perform online compensation for the forward slip model in the cold rolling process control system and improve the accuracy of the forward slip model, it is first necessary to determine the forward slip compensation factor. The forward slip compensation factor includes: the forward slip coefficient of each stand Base a b[i] And the adjustment factor an[i] of the number of rolled coils. After determining the front slip compensation factor, it is also necessary to determine the roll shape of the last frame of the current production line. The roll shape of the last frame includes: wool roller and bachelor.

[0043] S102: Determine a theoretical forward slip value according to the forward slip compensation factor;

[0044] After the f...

Embodiment 2

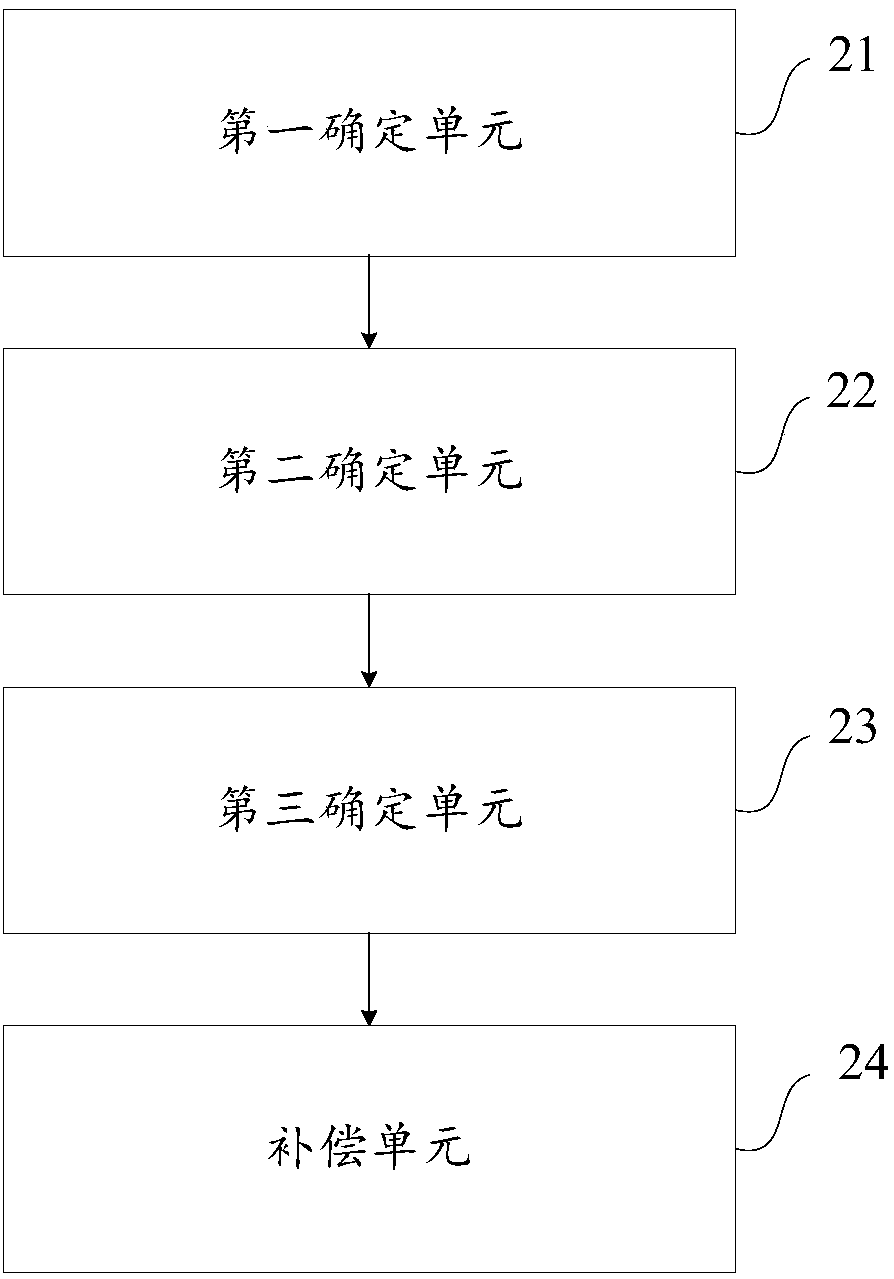

[0066] Corresponding to the first embodiment, this embodiment provides a device for compensating the slip value before tandem cold rolling, such as figure 2 As shown, the device includes: a first determining unit 21, a second determining unit 22, a third determining unit 23, and a compensation unit 24; wherein,

[0067] In order to make online compensation for the forward slip model in the cold rolling process control system and improve the accuracy of the forward slip model, the first determining unit 21 is used to determine the forward slip compensation factor, and the forward slip compensation factor includes: The base of the coefficient and the adjustment factor of the number of rolled coils.

[0068] After determining the front slip compensation factor, it is also necessary to determine the roll shape of the last frame of the current production line. The roll shape of the last frame includes: wool roller and bachelor.

[0069] After the roller type of the final frame is determ...

Embodiment 3

[0089] In actual applications, when using the method provided in the first embodiment and the device provided in the second embodiment to compensate the forward slip value of a tandem cold rolling mill #1 and #2, the details are as follows:

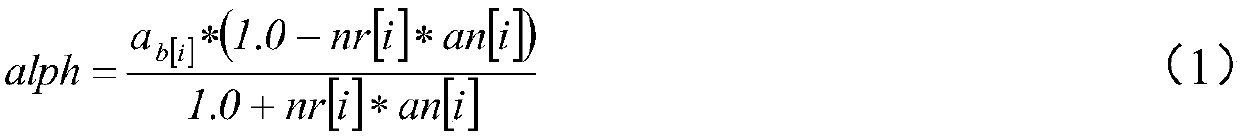

[0090] In order to make online compensation for the forward slip model in the cold rolling process control system and improve the accuracy of the forward slip model, it is first necessary to determine the forward slip compensation factor, and then determine the roll shape of the last stand of the current production line. Roll types include: wool roller and bachelor. The forward slip compensation factor includes: the base a of the forward slip coefficient of each frame b[i] And the adjustment factor an[i] of the number of rolled coils.

[0091] After the forward slip compensation factor is determined, the theoretical forward slip value is determined according to the forward slip compensation factor.

[0092] Specifically, the forward slip compen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com