Vector distribution control method for torque of distributed-driven electric automobile

An electric vehicle and torque vector technology, applied in electric vehicles, control drive, power management, etc., can solve problems such as inability to meet control requirements, limited drive torque output range, and increased driver manipulation burden.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0098] Embodiment: The distributed drive electric vehicle torque vector distribution control method is carried out according to the following steps:

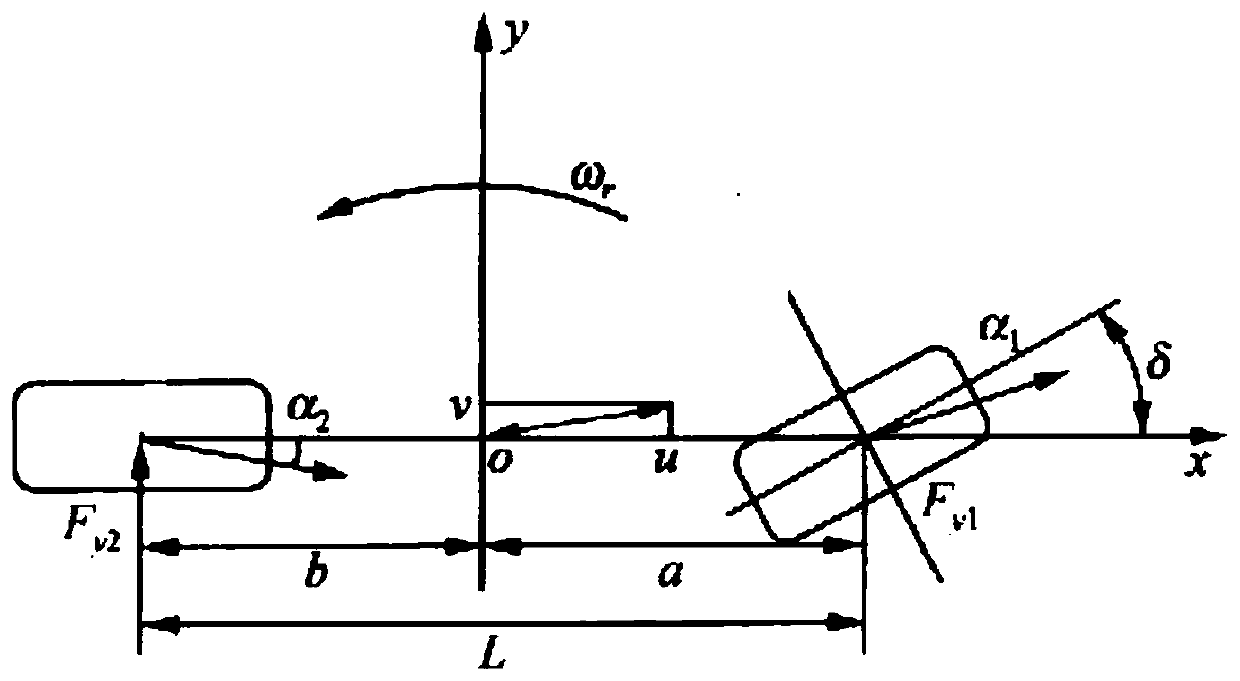

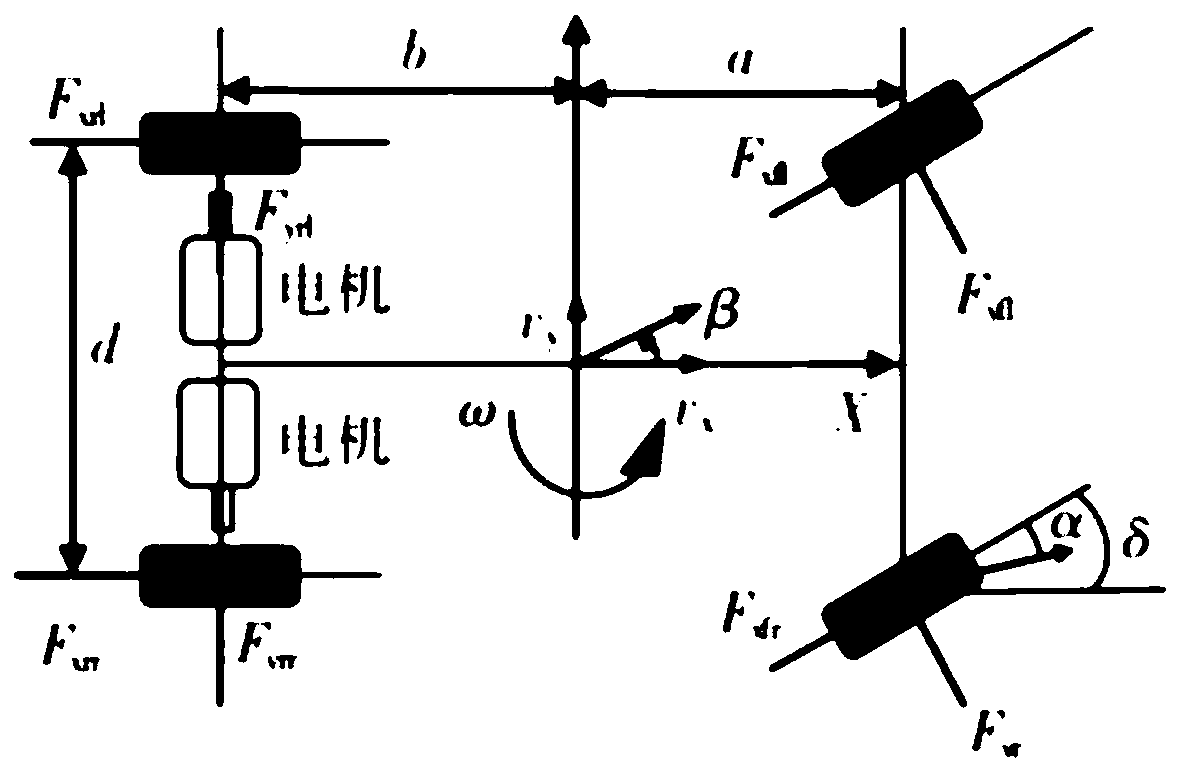

[0099] a. Establish a vehicle dynamics model to represent the relationship between the stability of the vehicle's driving state and the desired yaw rate, and use the Dugoff tire model to calculate the tire longitudinal slip rate;

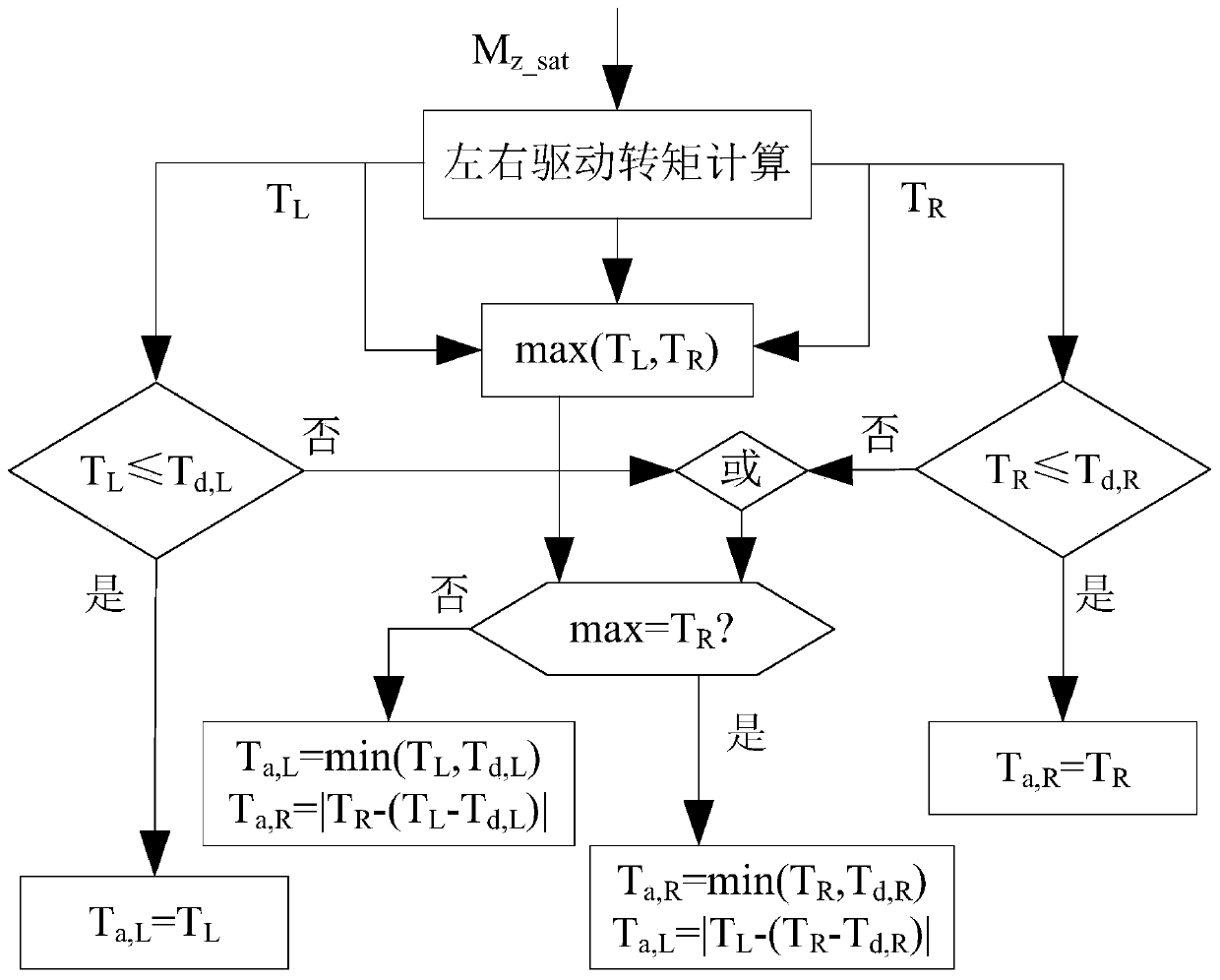

[0100] b. Use the vehicle dynamics model to design the yaw moment controller, and input the expected yaw angular velocity into the yaw moment controller to calculate the additional yaw moment; The minimum value between the maximum value of the moment and the additional yaw moment, specifically M z_sat =min(M z , M max ),Formula 1)

[0101] In the formula: M z_sat is the generalized additional yaw moment; M z Additional yaw moment; M max is the maximum value of driving torque that can be generated by the driving wheel motor;

[0102]c. According to the accelerator pedal opening and steering whee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com