Steel trestle provided with steel anchor pile and construction method of steel trestle

A construction method and technology for steel trestle bridges, which are applied to bridges, sheet pile walls, truss bridges, etc., can solve the problems of easy curling of pile bottoms, poor foundation stability, and difficult construction of steel pipe piles, and improve structural stability. Sex, the effect of large promotion value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

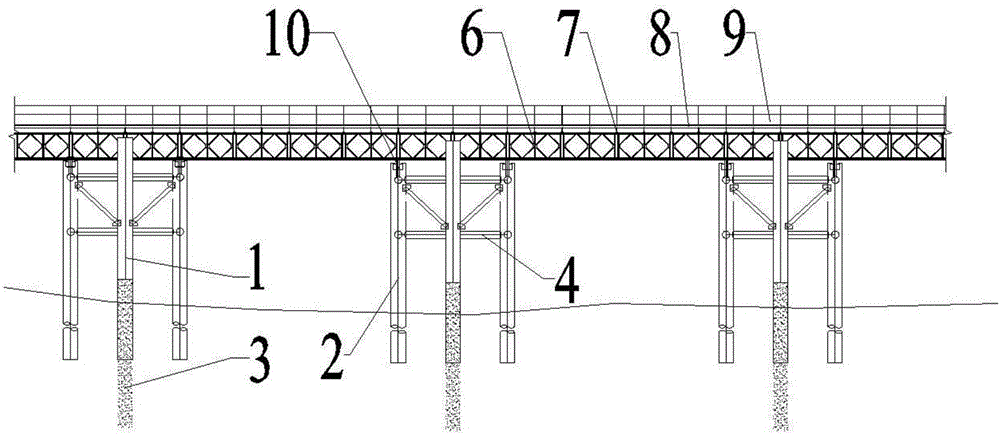

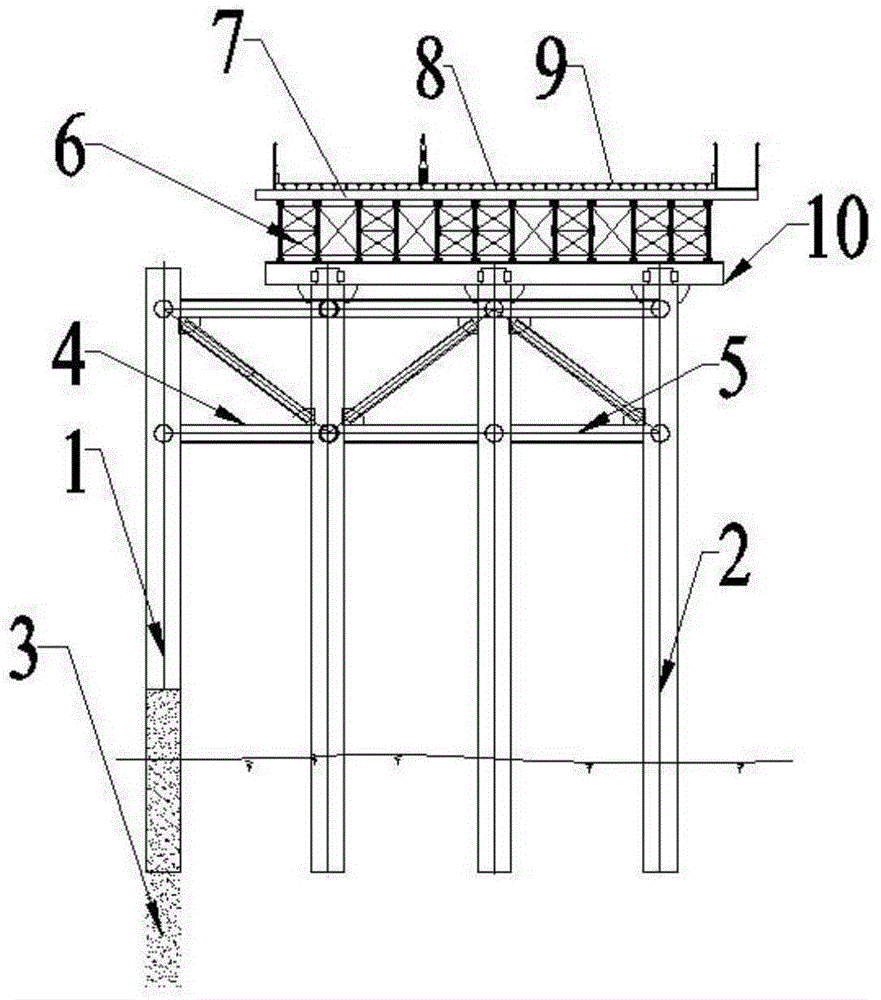

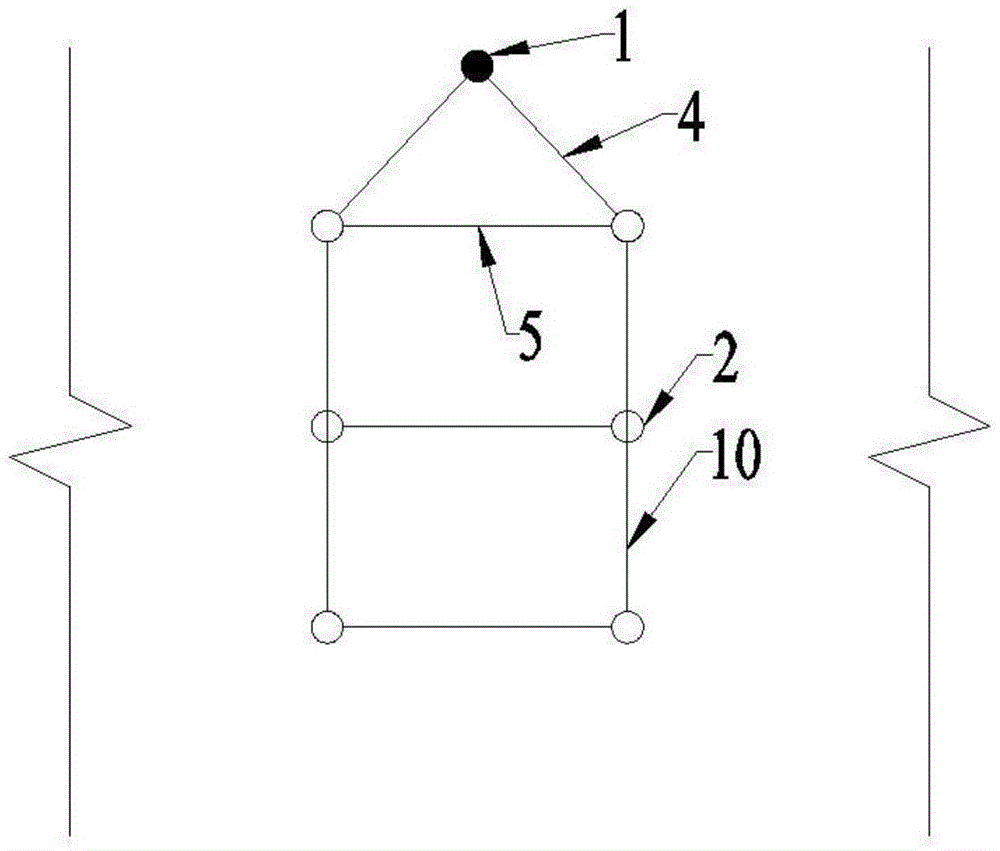

[0016] Such as Figure 1~3 , a steel trestle with steel anchor piles, the steel trestle supports the bridge deck through steel pipe piles 2 anchored on the river bed, the structure of the steel pipe piles 2 adopted in the present invention is a multi-row parallel formation group, by setting no less than two Multiple groups of steel pipe support structures support the bridge deck. The specific number needs to be determined according to the width of the river or the size of the bridge. The steel pipe support structure includes at least two rows of steel pipe piles. Three steel pipe piles 2 arranged in the direction of the bridge, such as image 3 As shown, the preferred scheme can be provided with three steel pipe piles 2, and the steel pipe piles 2 between the rows are connected as a whole using the second truss structure 5. The crossbeam 10 connects each row of steel pipe piles 2 into a whole, so that each group of steel pipe support structures forms a complete stressed overa...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com