Component pressing and twisting experimental device and method thereof

A technology of components and jacks, which is applied in the field of building structure tests, can solve the problems of complex experimental methods, unscientific experimental devices, and difficulty in studying the compression and torsion states of components.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0033] The present invention will be further described below in conjunction with accompanying drawing:

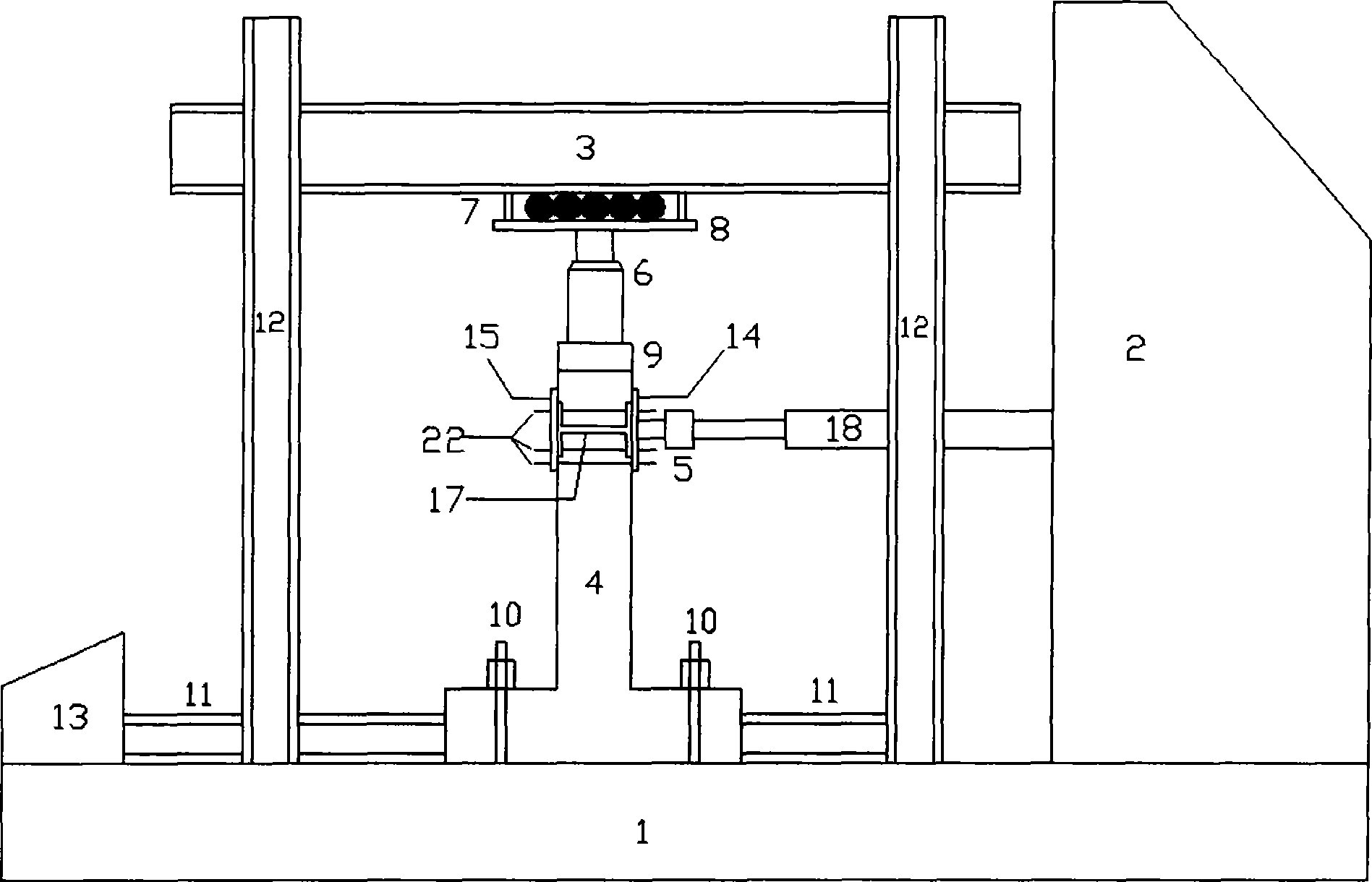

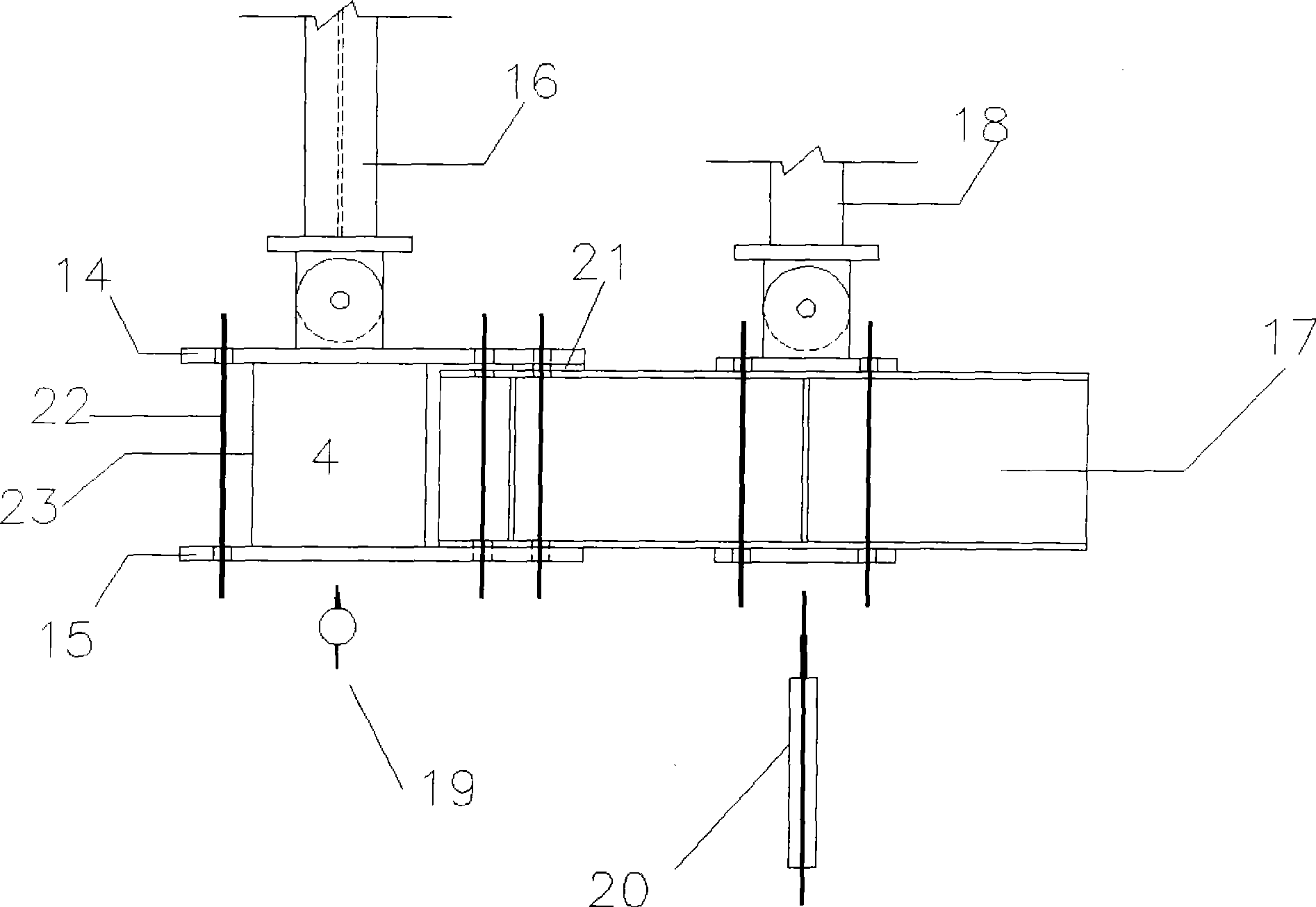

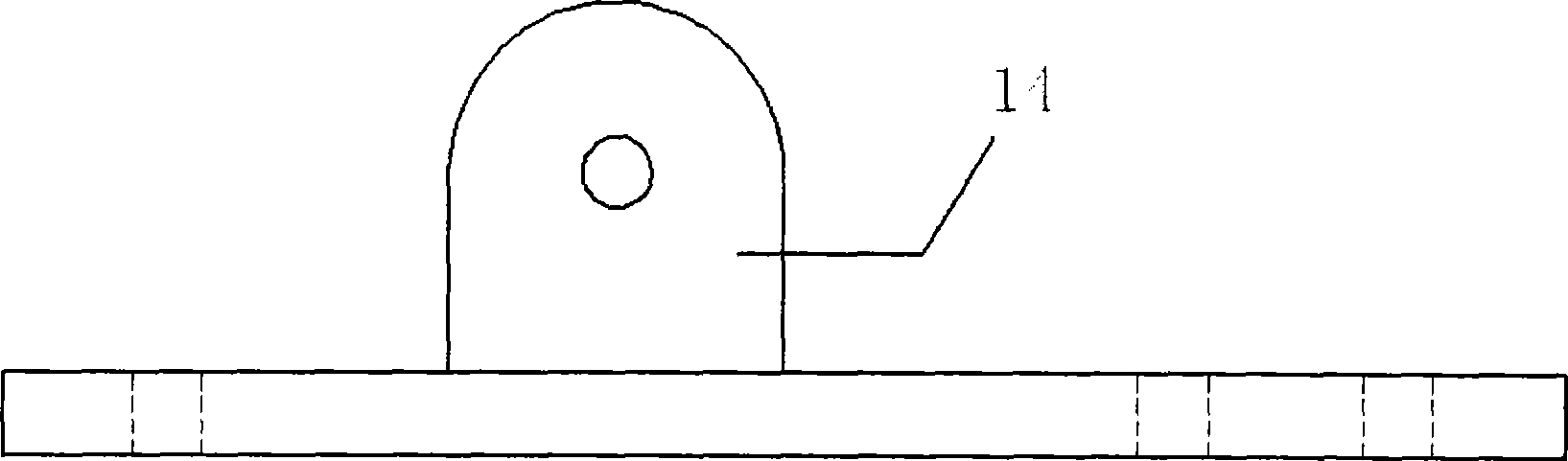

[0034] This embodiment provides an experimental device for this type of compression-twisting mixed action or pure torsion action, its structure is as follows figure 1 , figure 2 As shown, it includes pedestal 1, reaction wall 2, reaction beam 3, force sensor 5, vertical hydraulic jack 6, ball 7, steel plate 8, loading pad 9, ground anchor bolt 10, supporting steel beam 11, bracket 12, Baffle plate 13, front splint 14, rear splint 15, pure torsion loaded steel beam 16, loaded steel beam 17, horizontal force hydraulic jack 18, dial gauge 19, displacement gauge 20, and necessary data acquisition equipment for structural tests, etc. .

[0035] Such as figure 1 As shown, the reaction force beam 3 is fixed above the pedestal 1 through the bracket 12 , the right side of the pedestal is fixed by the reaction force wall 2 , and the component 4 is fixed on the pedestal 1 . One e...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com