Glass masking method using lasers

a laser and glass technology, applied in the field of glass windows and doors, can solve the problems of additional labor and additional opportunities, glass pane damage, and glass major surfaces may also be damaged, and achieve the effect of rapid scoring

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The following detailed description should be read with reference to the drawings, in which like elements in different drawings are numbered identically. The drawings, which are not necessarily to scale, depict selected embodiments and are not intended to limit the scope of the invention. Several forms of invention have been shown and described, and other forms will now be apparent to those skilled in art. It will be understood that embodiments shown in drawings and described above are merely for illustrative purposes, and are not intended to limit scope of the invention as defined in the claims which follow.

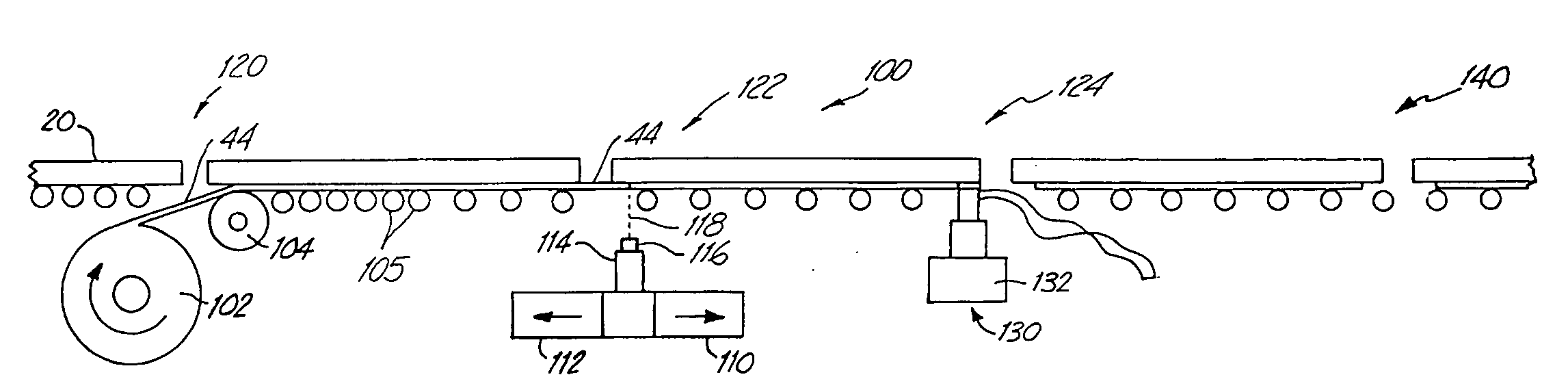

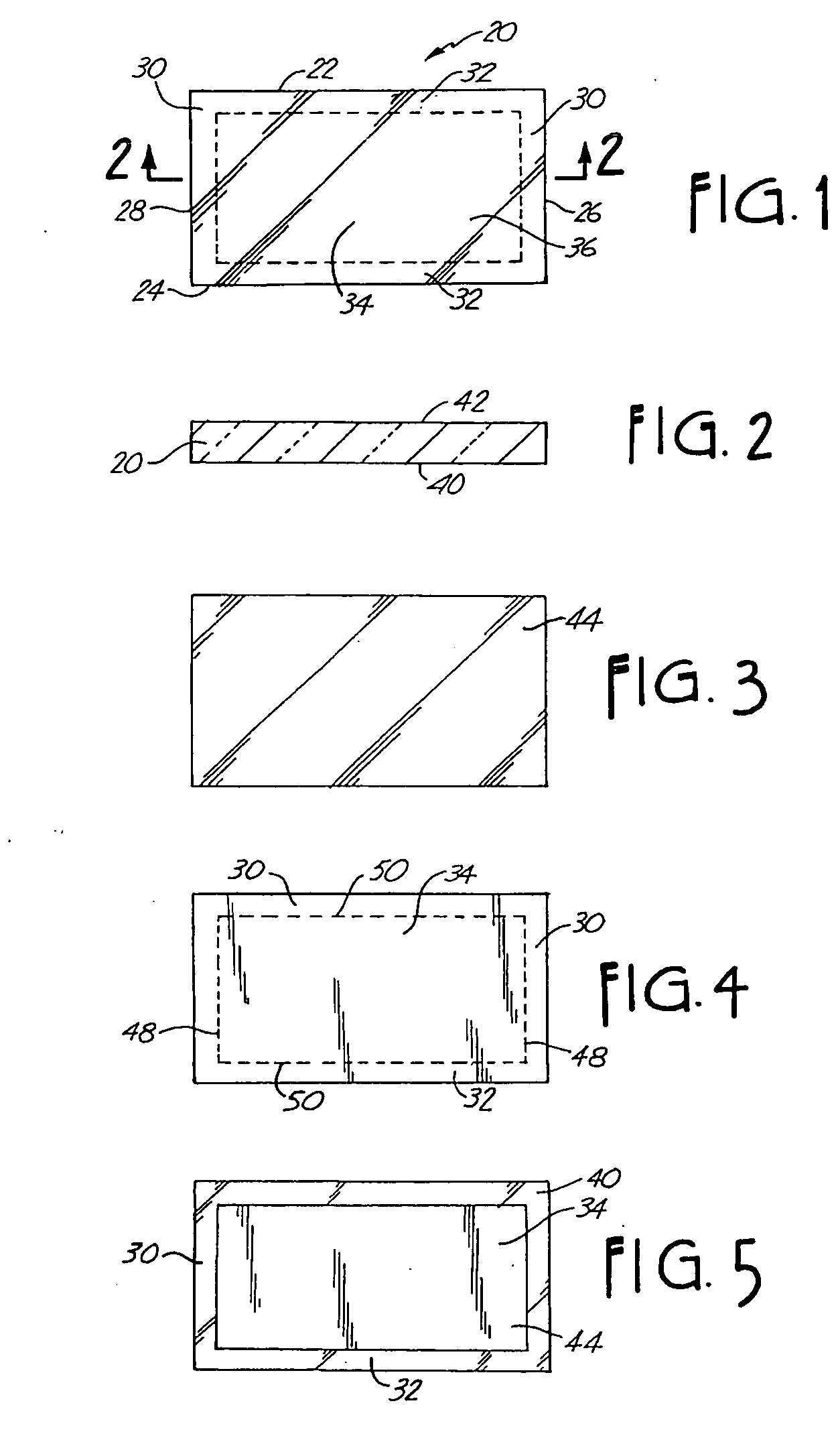

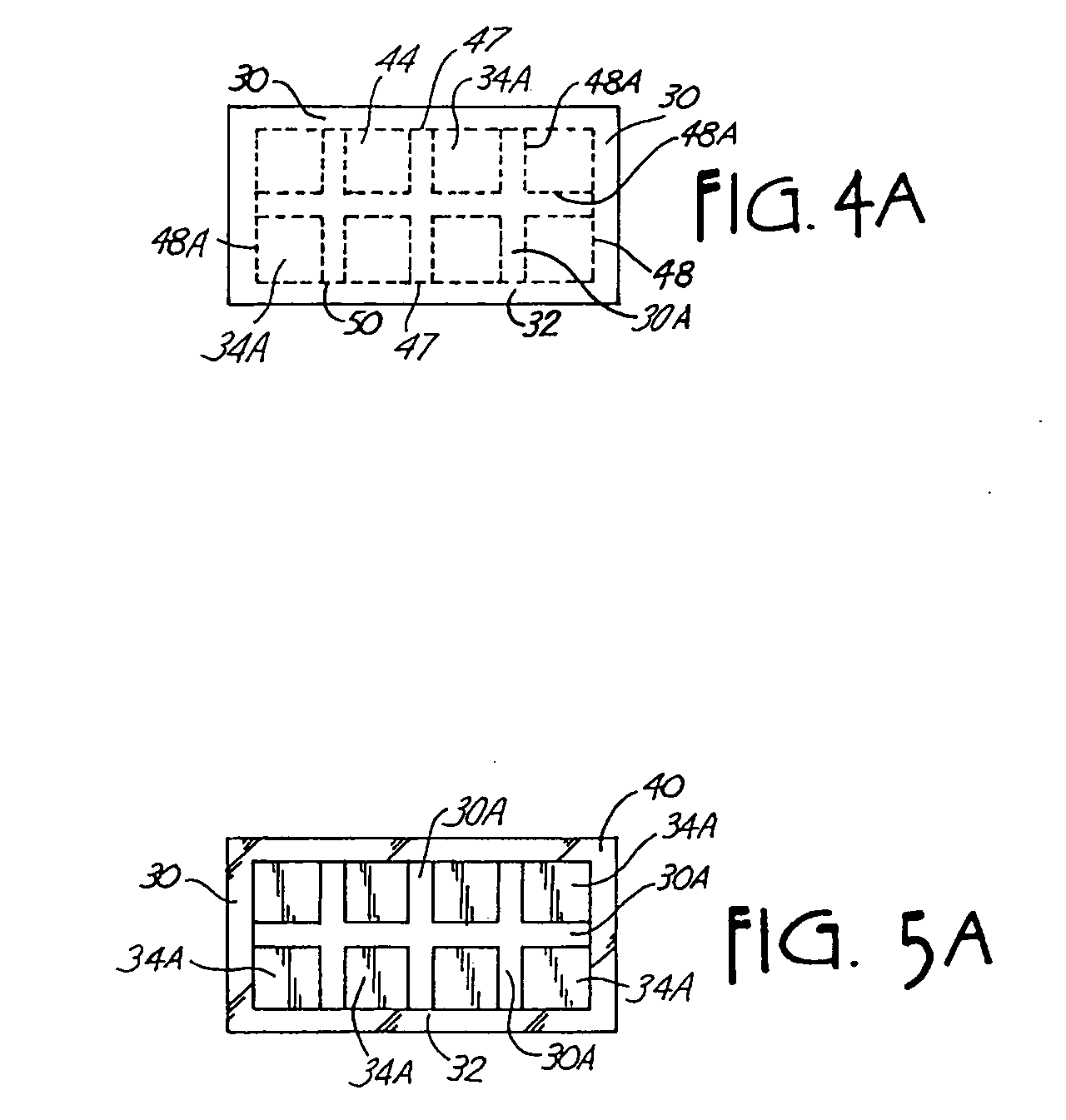

[0033] Referring now to FIG. 1, a glazing panel 20 is illustrated. Glazing panel 20 can be a single glass pane or an insulating glass unit including multiple glass panes separated by spacers. Glazing panel 20 includes generally a top edge 22, a bottom edge 24, a right side edge 26, and a left side edge 28. Glazing panel 20 includes generally a central region 34 surrounded...

PUM

| Property | Measurement | Unit |

|---|---|---|

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

| width | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com