Window frame section integrally welded with single push-pull window frame

A frame profile and window frame technology, which is applied to windows/doors, leaf frames, door/window protection devices, etc., can solve the problems of poor heat insulation performance, low wind pressure resistance level, and not firmness, etc., to improve the overall Strength and wind pressure resistance level, improved sealing effect, low cost effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

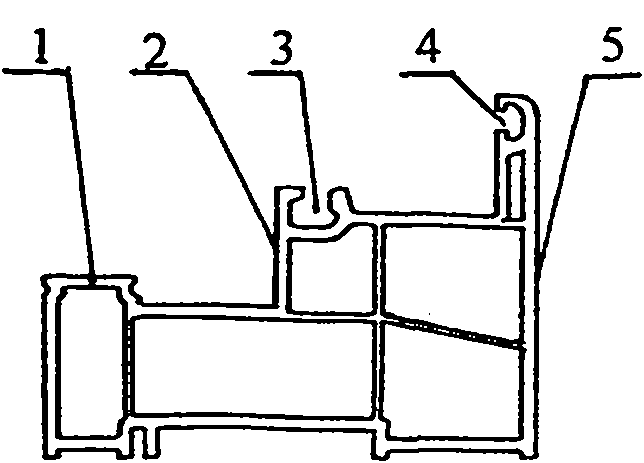

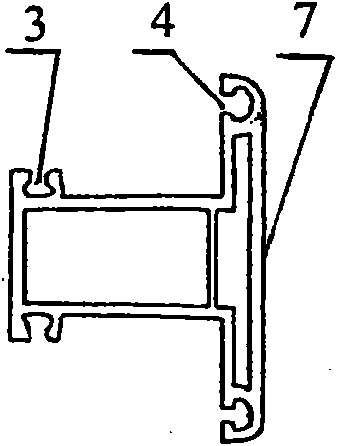

[0048] Embodiment 1, with reference to attached Figure 1-9, the single push-pull window frame is welded into an integrated window frame profile, and the profiles required to make the window frame 15 include frame profile 5, stile frame profile 6, small stile profile 7, and sealing strip 8. The processing process is to press the frame profile 5 according to the required Cut out the upper and lower frames and two vertical frames according to the required size, and cut out the V-shaped hole 13 for welding with the middle frame 6 at the required position and size of the two vertical frames 5, and cut out the V-shaped hole 13 for welding with the middle frame 6 at the required position and size of the lower frame 5. The small V-shaped hole 13-1 for the welding of the middle stile profile 7 is to cut the middle stile frame 6 into the shape of V tenon 14 at the two ends according to the required length, and cut out the welding with the small middle stile section 7 at the required pos...

Embodiment 2

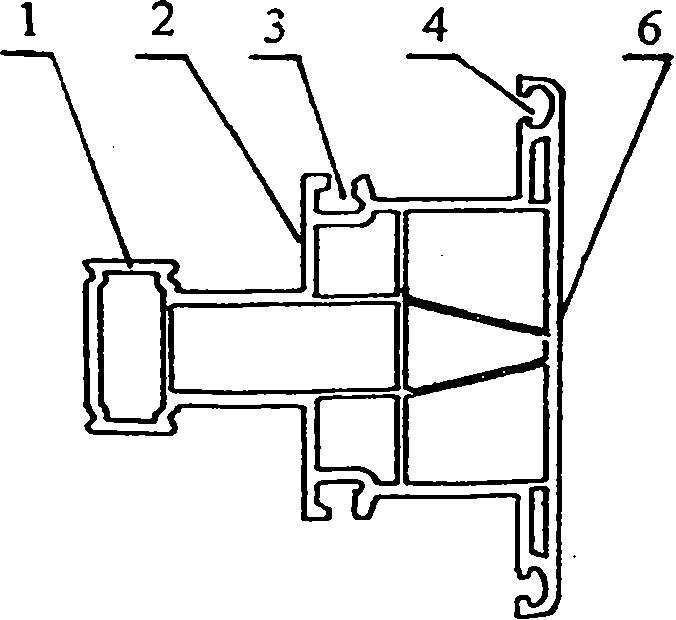

[0049] Embodiment 2, with reference to attached Figure 3-5 , 10 to 15, which can realize the single push-pull window frame welded into an integrated window frame profile. The difference from Example 1 is that the profile structure of the frame 5 and the stile frame 6 is equipped with a heat insulation curtain 21 for connection. The curtain connection groove 20, the heat insulation curtain 21 is connected with the frame 5 and the stile frame 6 through the side heat insulation curtain connection groove 20, forming the overall heat insulation and sealing structure of the window frame 15.

Embodiment 3

[0050] Embodiment 3, with reference to attached Figure 3-4 , 16-22, can realize the single push-pull window frame welded into an integral window frame profile, and the difference from embodiment 1 is: the profile structure of the frame 5 and the stile frame 6 has a glideway 1-1, the window frame 15 The glide path 1-1 on the lower frame 5 directly does the glide path of the window sash 18. The glide path 1-1 of the middle stile frame 6 in the downward direction in the window frame 15 is assembled with the upper slide path heightening bar 11-1 to form the upper slide path of the window sash 18.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com