High chromium content ferrite stainless steel and manufacturing method thereof

A technology of high-chromium ferrite and manufacturing method, which is applied in the direction of manufacturing tools, metal rolling, metal rolling, etc., can solve the problems of increasing manufacturing costs, and achieve the goal of reducing grinding intensity, reducing smelting intensity, and reducing smelting costs Effect

Inactive Publication Date: 2010-12-01

BAOSHAN IRON & STEEL CO LTD

View PDF5 Cites 0 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, adding Mo will significantly increase the manufacturing cost of steel

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

Login to View More

Login to View More Abstract

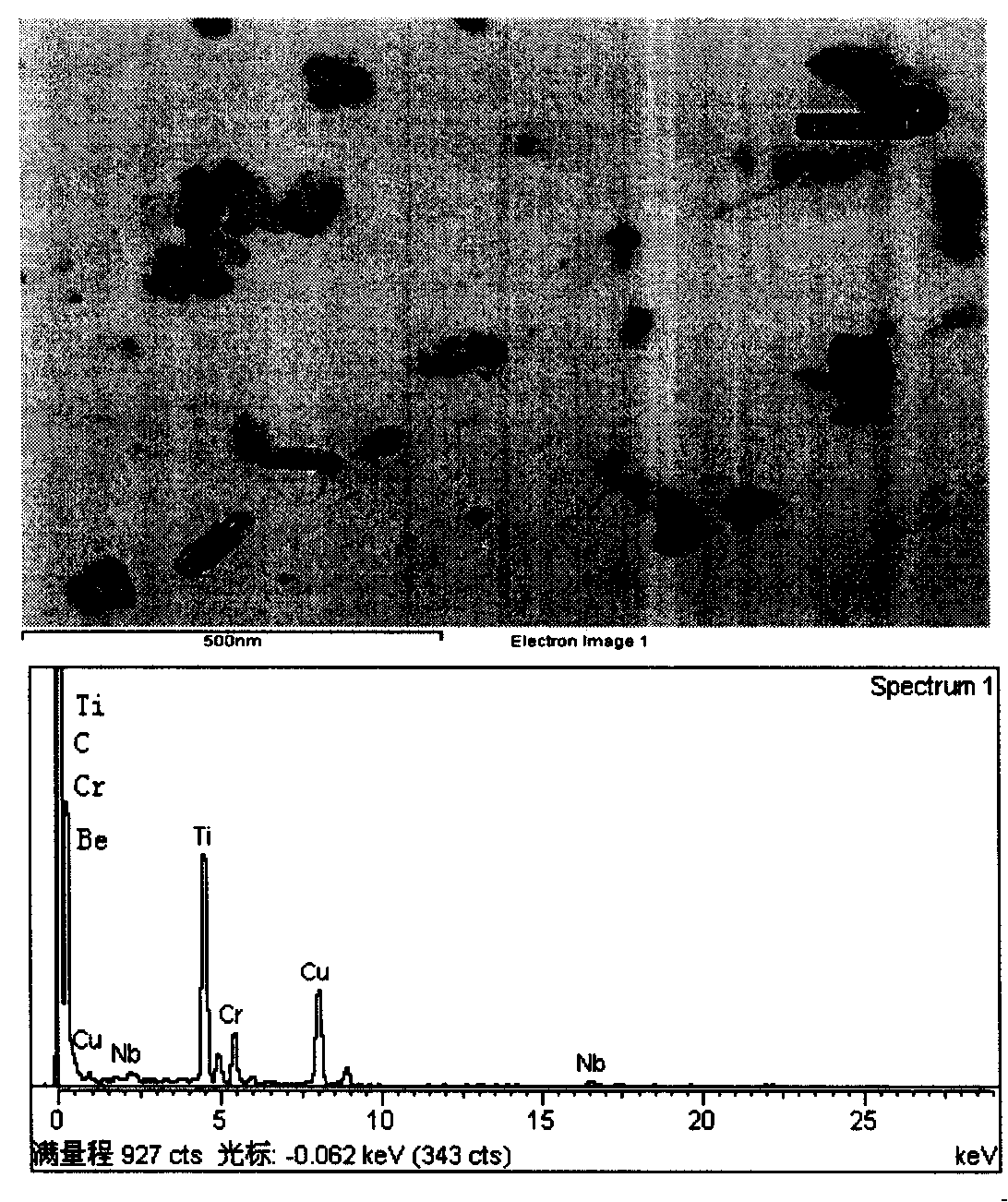

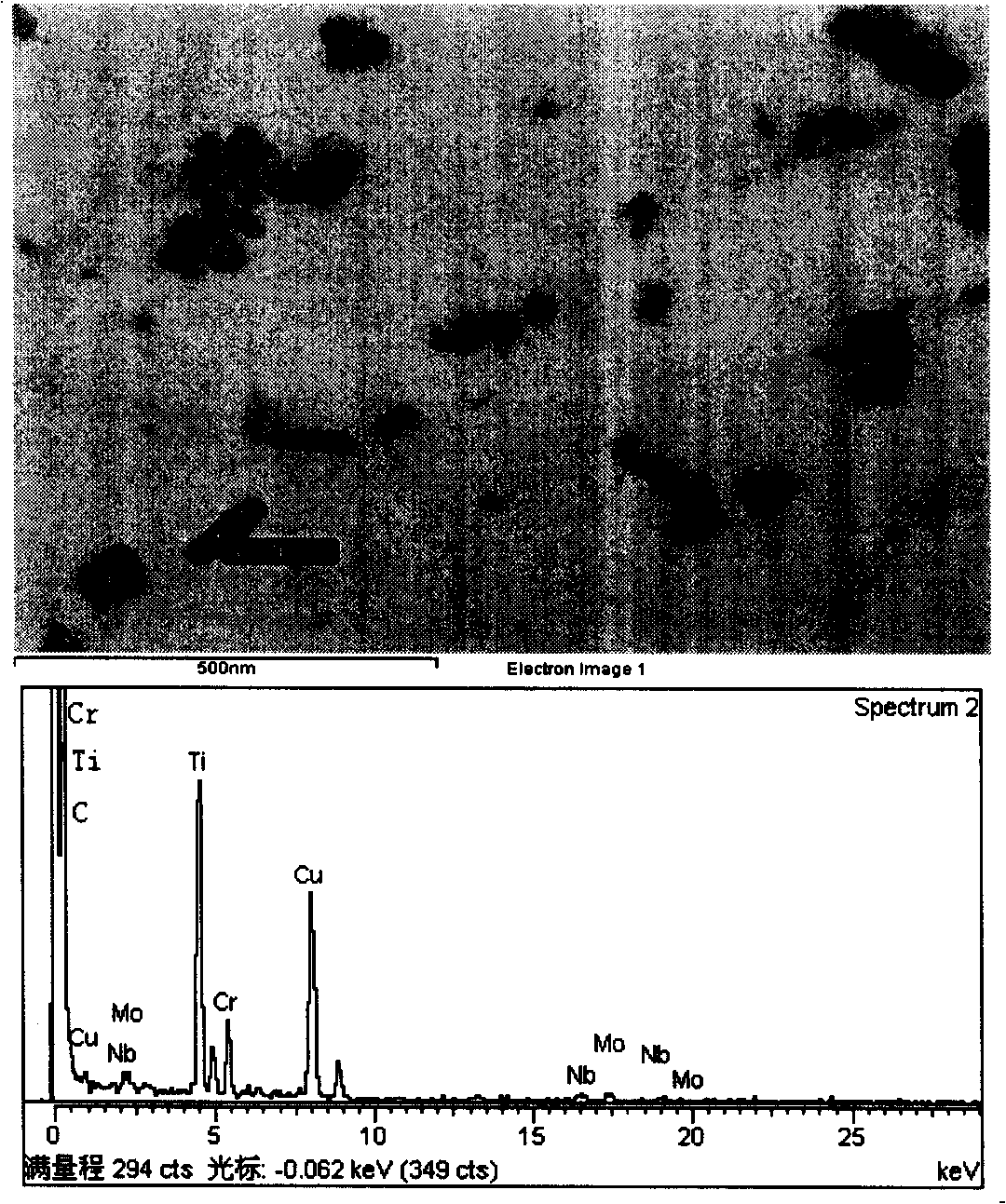

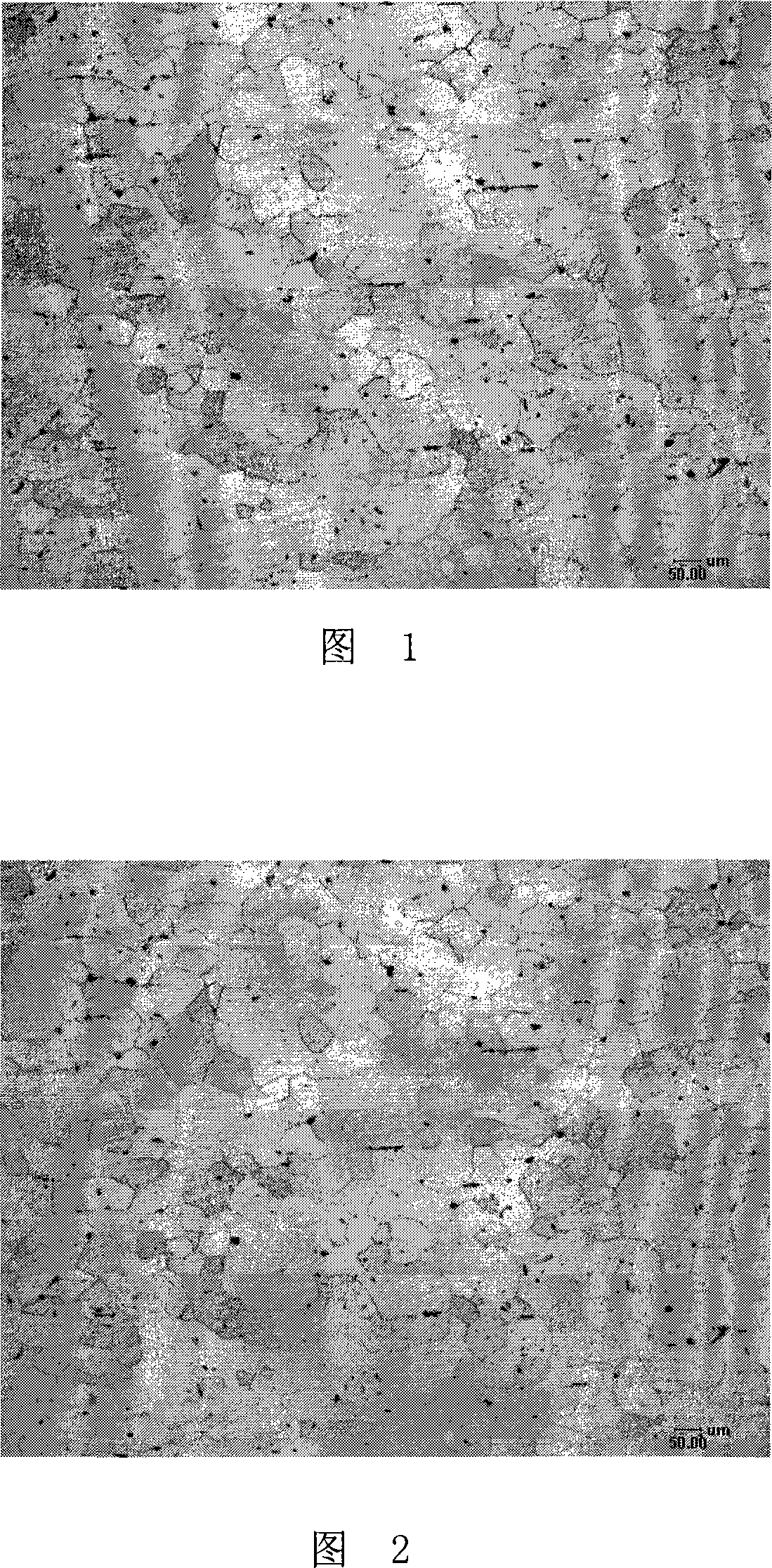

The invention discloses high chromium ferritic stainless steel and a manufacturing method thereof. The high chromium ferritic stainless steel is characterized in that the high chromium ferritic stainless steel comprises chemical elements according to the following weight percentage: less than or equal to 0.015 percent of C, less than or equal to 0.020 percent of N, less than or equal to 1.0 percent of Si, less than or equal to 1.0 percent of Mn, less than or equal to 0.035 percent of P, less than or equal to 0.010 percent of S, 20 to 25 percent of Cr, 0.30 to 0.50 percent of Cu, less than or equal to 0. 5 percent of Ti and Nb, and the balance being Fe, wherein (Ti / 48+Nb / 93) / (C / 12+N / 14) is more than 1.5. The manufacturing method comprises the: 1) a step of continuous casting or die casting, in which raw materials are primarily rolled into steel billets after the die casting; 2) a step of rolling, in which the final rolling temperature of steel plates is between 800 and 950 DEG C, and the gradual cooling is performed after the rolling; 3) a step of continuous annealing, in which the temperature is between 850 and 950 DEG C; 4) a step of the removal of oxide coating; 5) a step of cold rolling; and 6) a step of continuous annealing after the recrystallization. The ferritic stainless steel has the advantages of stronger corrosion resistance, higher plasticity and good deep drawability.

Description

A kind of high chromium ferritic stainless steel and its manufacturing method technical field The invention relates to a stainless steel, in particular to a ferritic stainless steel. Background technique With the soaring price of metal Ni, the price of austenitic stainless steel is also rising. The development of ferritic stainless steel with low cost and excellent corrosion resistance and cold formability has become an important topic for stainless steel manufacturers. Ferritic stainless steel does not contain Ni or only contains a small amount of Ni, and the price is low. In addition to being stainless and general corrosion resistance, it has excellent local corrosion resistance such as chloride stress corrosion resistance, pitting corrosion resistance, and crevice corrosion resistance. It is widely used in household appliances. It has a wide range of applications and broad development prospects in the fields of industry, automobile industry, housing construction, petroc...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Patents(China)

IPC IPC(8): C22C38/20C22C38/26C22C38/28C22C33/04C21D8/00C21D1/26B21B37/00B21D5/00B21B45/04C23G1/08

Inventor 董文卜马立

Owner BAOSHAN IRON & STEEL CO LTD

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com