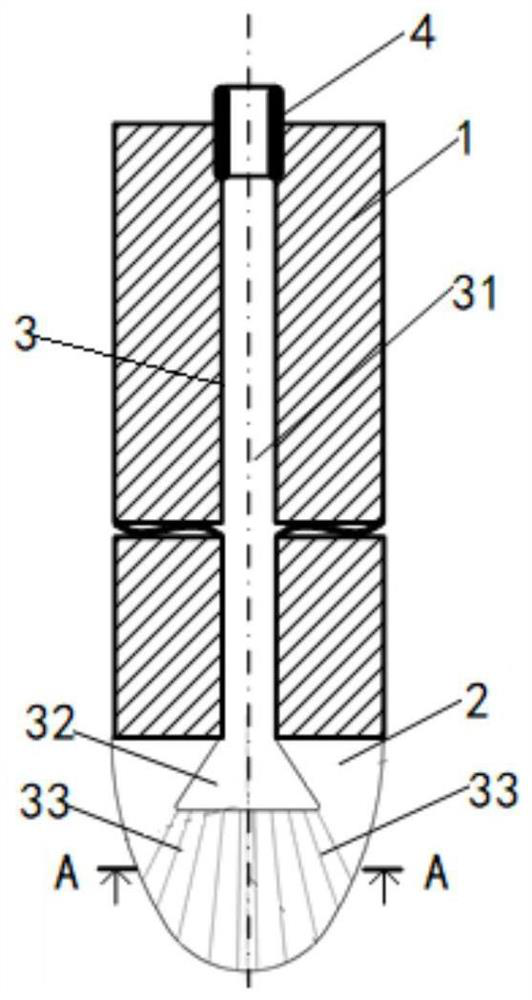

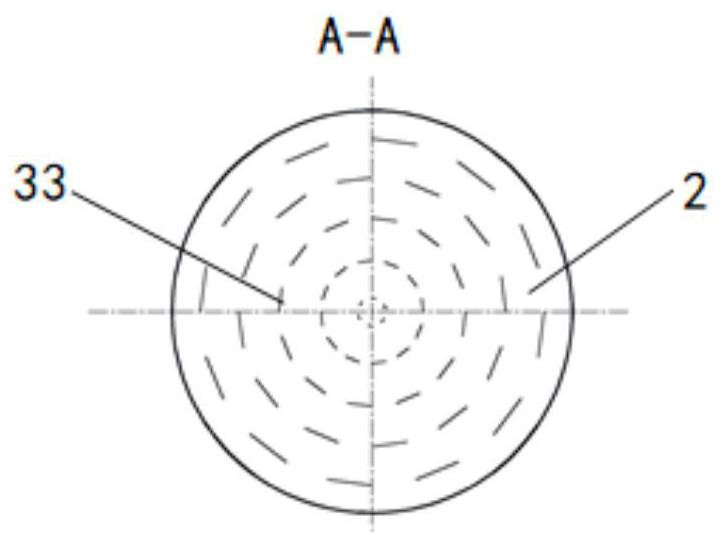

A high-quality steel continuous casting argon blowing stopper, stopper argon blowing system and argon blowing method

A high-quality stopper technology, applied in casting equipment, casting melt containers, manufacturing tools, etc., can solve problems such as argon blowing flow rate not suitable for casting conditions, fluctuations and tumbling of steel slag interface in mold, secondary oxidation of molten steel, etc. To achieve the effect of preventing severe fluctuations and tumbling of steel slag interface, improving size and distribution state, and preventing secondary oxidation of molten steel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0039] Embodiment 1: Taking sulfur-free high-quality steel with an aluminum content of 0.025% as an example, the method of continuously casting argon-blowing high-quality steel using the above-mentioned argon blowing system and the resulting effect will be described in detail. The method of continuous casting argon blowing comprises the following steps:

[0040] 1) Before continuous casting, when the molten steel flows into the tundish 6, the source of argon is turned on, and argon is supplied to the gas channel 3 of the continuous casting argon-blowing stopper rod, and the pressure of the argon supply is kept at 0.3Mpa. The flow rate is 2.0L / min, and the flow is continued for 10 minutes to keep the gas channel 3 unblocked;

[0041] 2) The continuous casting argon blowing stopper rod is lifted to make the molten steel enter the crystallizer 8, keep the argon gas supply pressure at 0.3Mpa, increase the argon gas flow rate to 4.0L / min, and continue to feed it for 15 minutes, and...

Embodiment 2

[0044] Example 2: Taking sulfur-containing aluminum-containing high-quality steel with an aluminum content of 0.025% and a sulfur content of 0.020% as an example, the method of continuously casting argon-blowing high-quality steel using the above-mentioned argon blowing system and the resulting effect will be explained in detail . The method of continuous casting argon blowing comprises the following steps:

[0045] 1) Before continuous casting, when the molten steel flows into the tundish 6, the source of argon is turned on, and argon is supplied to the gas channel 3 of the continuous casting argon-blowing stopper rod, and the pressure of the argon supply is maintained at 0.4Mpa. The flow rate is 3.0L / min, and it is continuously fed for 10 minutes to keep the gas channel 3 unblocked;

[0046] 2) The continuous casting argon blowing stopper rod is lifted to make the molten steel enter the crystallizer 8, keep the argon gas supply pressure at 0.4Mpa, increase the flow rate of ...

Embodiment 3

[0049] Example 3: Taking high-sulfur, high-aluminum high-quality steel with an aluminum content of 0.040% and a sulfur content of 0.025% as an example, the method of continuously casting and blowing argon on high-quality steel using the above-mentioned argon blowing system and the resulting effects . The method for continuous casting argon blowing comprises the following steps:

[0050] 1) Before continuous casting, when the molten steel flows into the tundish 6, the source of argon is turned on, and argon is supplied to the gas channel 3 of the continuous casting argon-blowing stopper rod, and the pressure of the argon supply is maintained at 0.5Mpa, and the argon The flow rate is 3.0L / min, and it is continuously fed for 10 minutes to keep the gas channel 3 unblocked;

[0051] 2) The continuous casting argon blowing stopper rod is lifted to make the molten steel enter the crystallizer 8, keep the argon gas supply pressure at 0.5Mpa, increase the flow rate of the argon gas to...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com