Ferrite stainless steel with good polishing performance and manufacturing method thereof

A manufacturing method and ferrite technology, which is applied in the field of ferritic stainless steel, can solve the problems of few studies on the polishing properties of ferritic stainless steel

Active Publication Date: 2014-04-23

BAOSTEEL DESHENG STAINLESS STEEL

View PDF6 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

However, for applications that require surface decoration such as BA and high-grade mirror abrasives, the existing Ti, Nb double-stabilized or Ti single-stabilized ferritic stainless steel

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Login to View More

Login to View More PUM

Login to View More

Login to View More Abstract

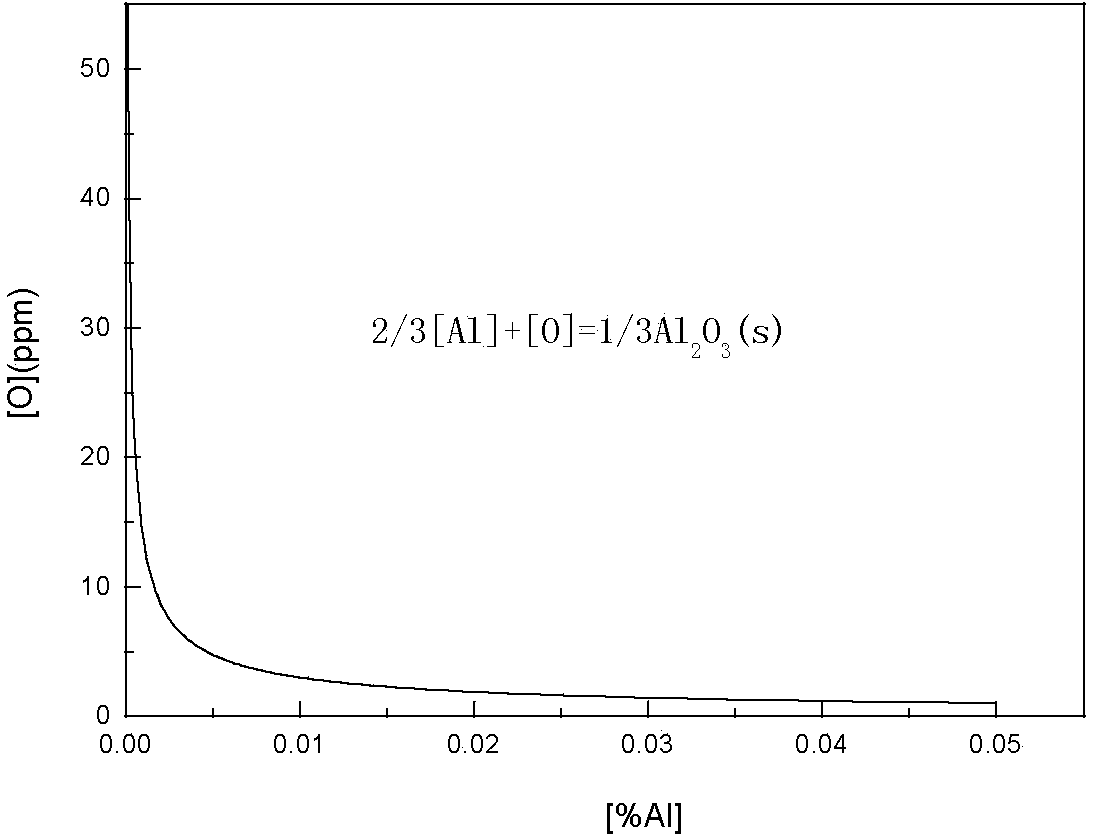

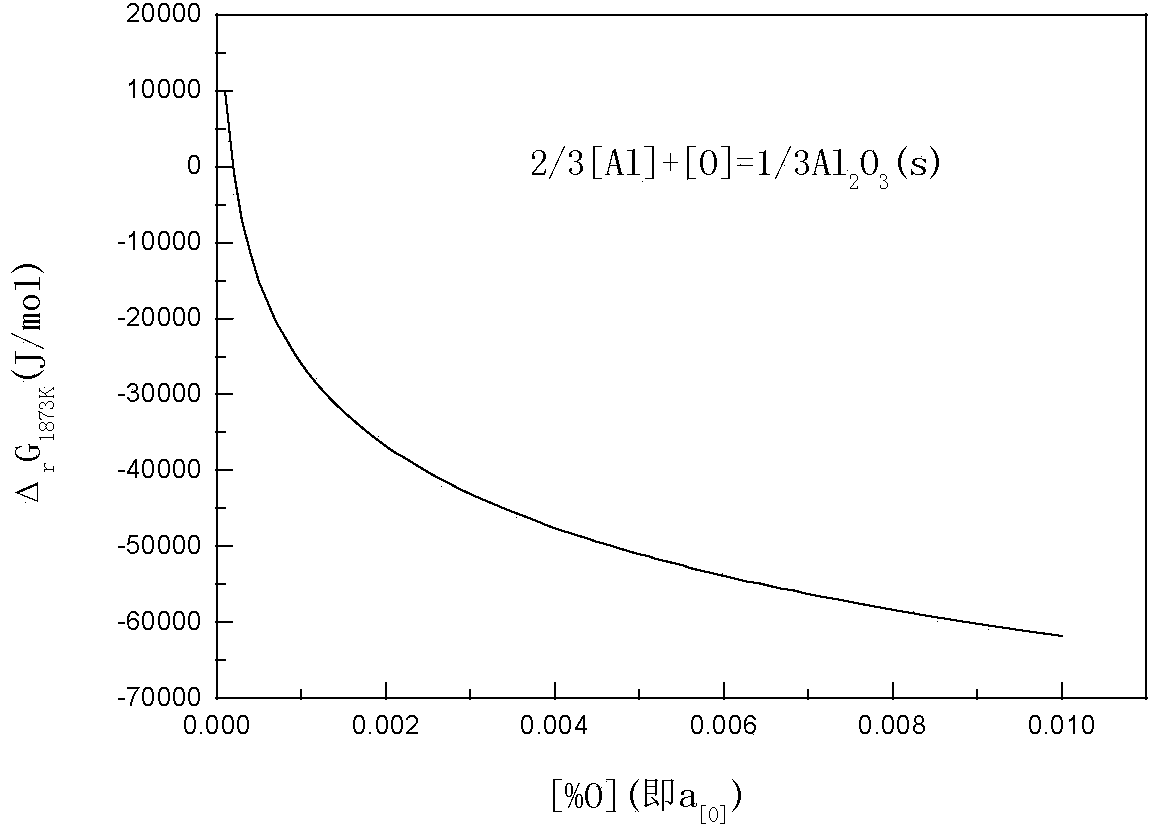

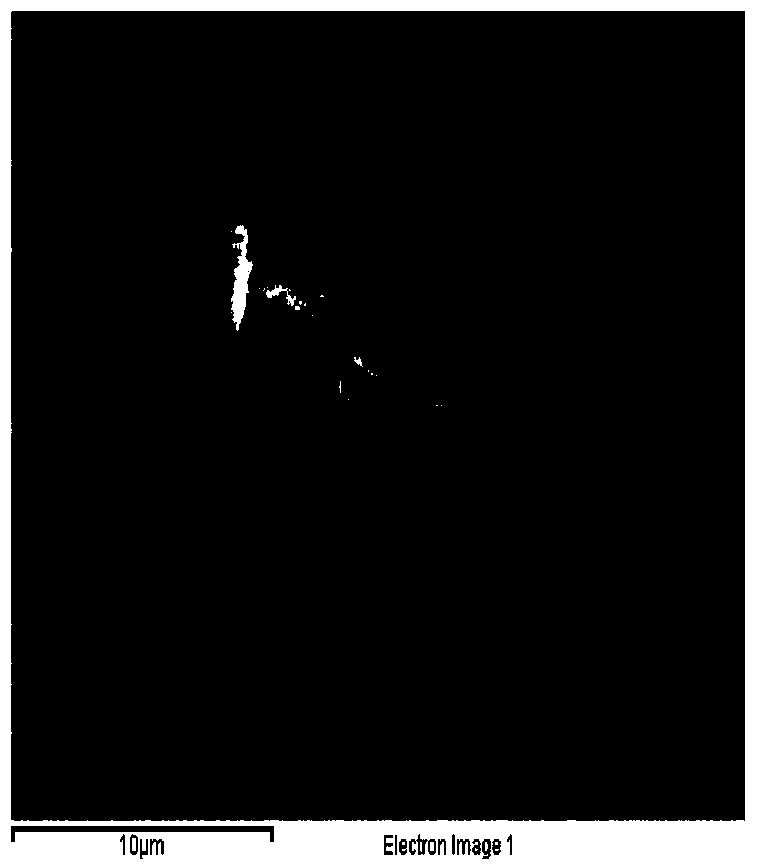

The invention relates to ferrite stainless steel with good polishing performance and a manufacturing method thereof. The ferrite stainless steel comprises the following components in percentage by weight: not more than 0.015% of C, not more than 0.020% of N, not more than 0.5% of Si, not more than 0.5% of Mn, not more than 0.030% of P, not more than 0.010% of S, 18-22% of Cr, 0.30-0.50% of Cu, not more than 0.30% of Ni, 0.3-0.5% of Nb, not more than 0.002% of Al, not more than 0.005% of O and the balance of Fe and inevitable impurities. According to the manufacturing method provided by the invention, by using Nb for stabilization and controlling the oxygen content and the type of inclusions in the steel, the precipitation of a micro-sized second phase and the generation of brittle inclusions can be avoided, so that the polishing performance of the ferrite stainless steel can be ensured.

Description

technical field [0001] The invention relates to a ferritic stainless steel, in particular to a ferritic stainless steel with good polishing performance and a manufacturing method thereof. Background technique [0002] Ferritic stainless steel, especially ferritic stainless steel containing carbon and very low nitrogen, has excellent corrosion resistance, formability and weldability, and has high product cost performance. It is the world's key resource for developing and replacing austenitic stainless steel Energy-saving products can be widely used in construction, home appliances, kitchen utensils, products and other fields. However, for applications that require surface decoration such as BA and high-grade mirror abrasives, the existing Ti, Nb double-stabilized or Ti single-stabilized ferritic stainless steel is not suitable. [0003] Much research has been done on improving the formability of ferritic stainless steels, but little research has been done on the polishing pr...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More IPC IPC(8): C22C38/48C22C38/26C21C7/06

Inventor 董文卜马立袁龙杨智辉

Owner BAOSTEEL DESHENG STAINLESS STEEL

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com