Niobium-containing alloying hot-galvanizing steel for automobile outer cover part and manufacturing method of steel

A technology of niobium alloying and outer covering parts, which is applied in the field of steel manufacturing, can solve problems such as unsatisfactory corrosion resistance, and achieve the effects of good isotropy, good corrosion resistance, and long service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

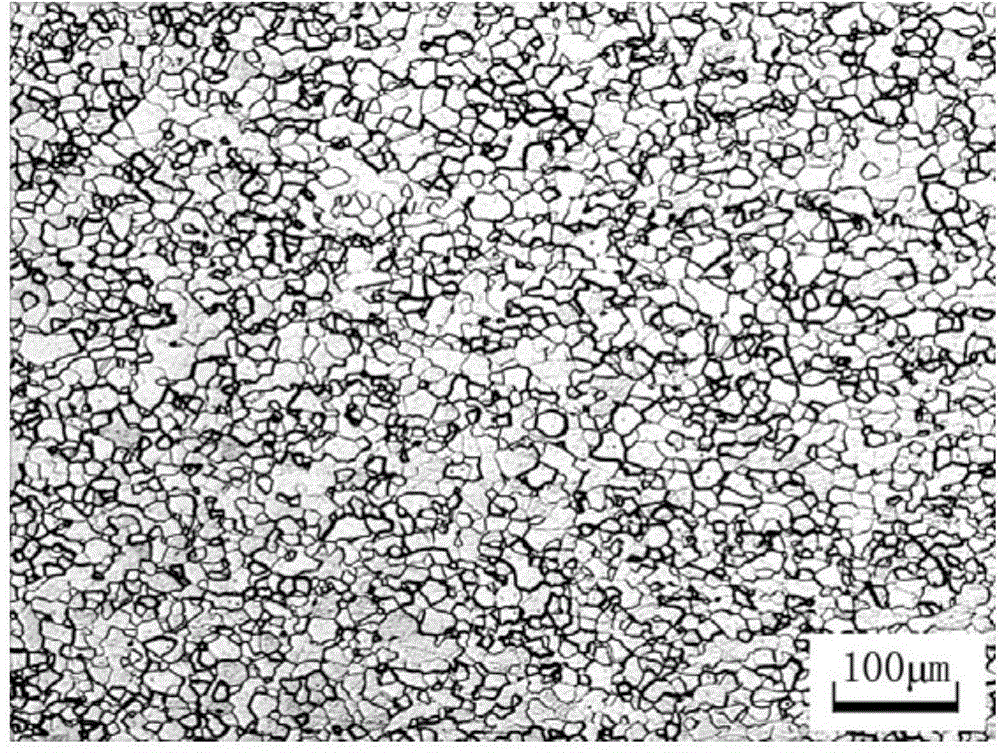

[0023] Below in conjunction with accompanying drawing and specific embodiment the present invention will be described in further detail:

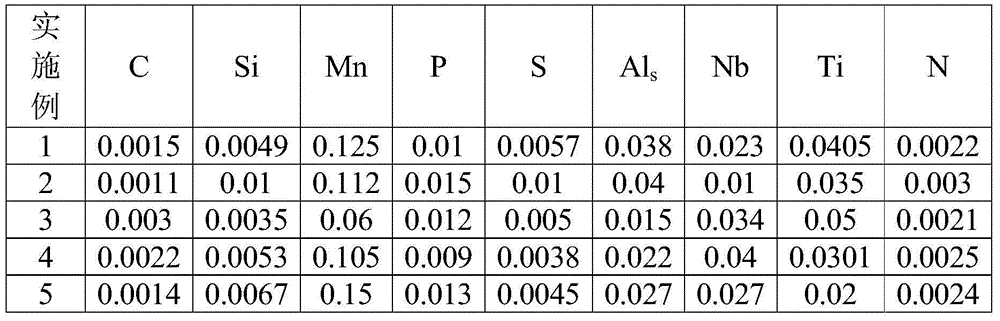

[0024] Examples 1 to 5 The niobium-containing alloyed hot-dip galvanized steel for the outer cover of automobiles, the chemical composition and weight percentage in the steel are designed according to Table 1 respectively.

[0025] Chemical composition design in each embodiment steel of table 1

[0026]

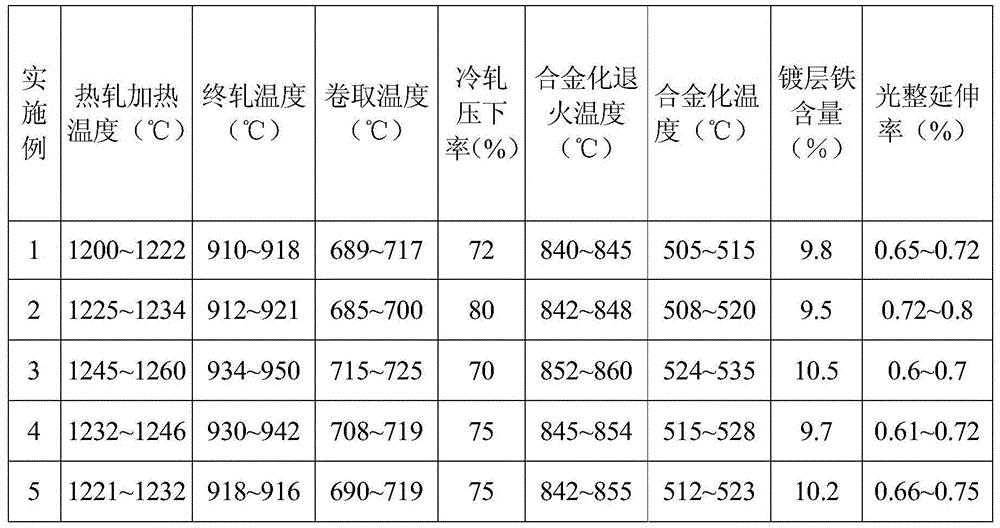

[0027] Embodiments 1 to 5 The manufacturing methods of steels for alloyed hot-dip galvanized automobile outer coverings containing niobium all include steelmaking, hot rolling, cold rolling, continuous annealing and alloying galvanizing processes in sequence, and the difference is that in the manufacturing process The process parameters involved in different processes are designed differently, and the specific process parameters are designed in Table 2 below.

[0028] The processing parameters of each embodiment of table 2

[0029] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com